Continuous reducing die for swelling-pressure-formed axle housings of small and medium-sized automobiles

A small and medium-sized, diameter-reducing technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of small external pulling force of the mandrel, inconvenient replacement of the mandrel, and small diameter-reducing deformation. The effect of easy control of wall thickness and large amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

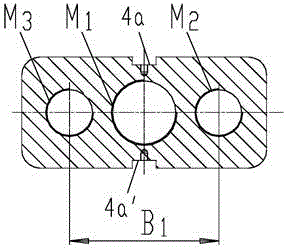

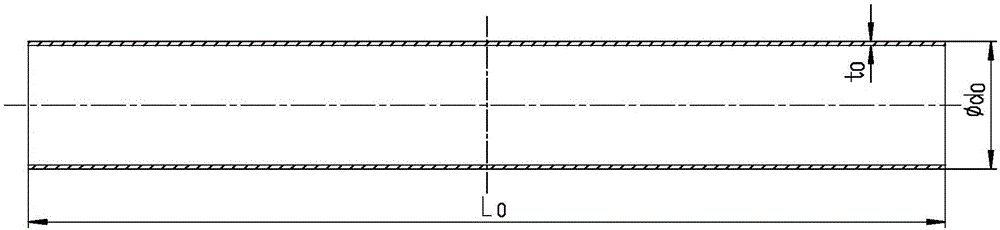

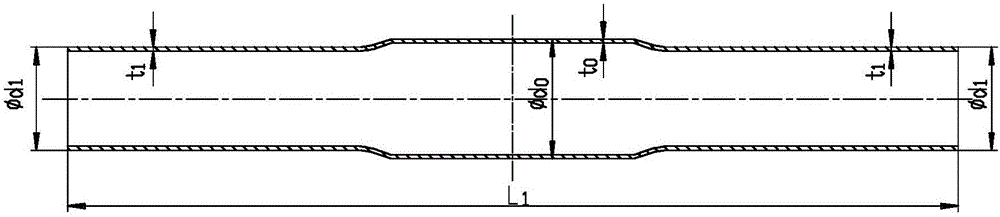

[0031] figure 1 It is a schematic diagram of the initial tube blank in the embodiment of the present invention, and the seamless steel round tube selected has an outer diameter of Wall thickness t 0 =4.5mm, the length is L 0 =1050mm. The diameter is reduced by using the continuous diameter reduction mold, and the outer diameter of both ends of the tube blank is formed by the first diameter reduction station Wall thickness t 1 =4.9mm, length L 1 =1080mm, such as figure 2 Shown; the outer diameter of both ends of the tube blank formed by the second reducing station Wall thickness t 2 =5.4mm, length L 1 =1110mm, such as image 3 shown.

[0032] The continuous diameter-reducing mold for small and medium-sized automobile expansion and compression forming axle housings in this embodiment is used on a three-way hydraulic press, and mainly includes an upper mold plate 11, an upper mold backing plate 16, a lower mold plate 23, an upper mold I15a, an upper mold II19a, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com