Stripping rib rolling head and steel bar thread machine tool

A technology of rolling head and rib stripping, applied in the field of steel bar connection machinery manufacturing, can solve the problems of inability to meet processing requirements, low thread accuracy, high labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in combination with specific implementation methods and accompanying drawings.

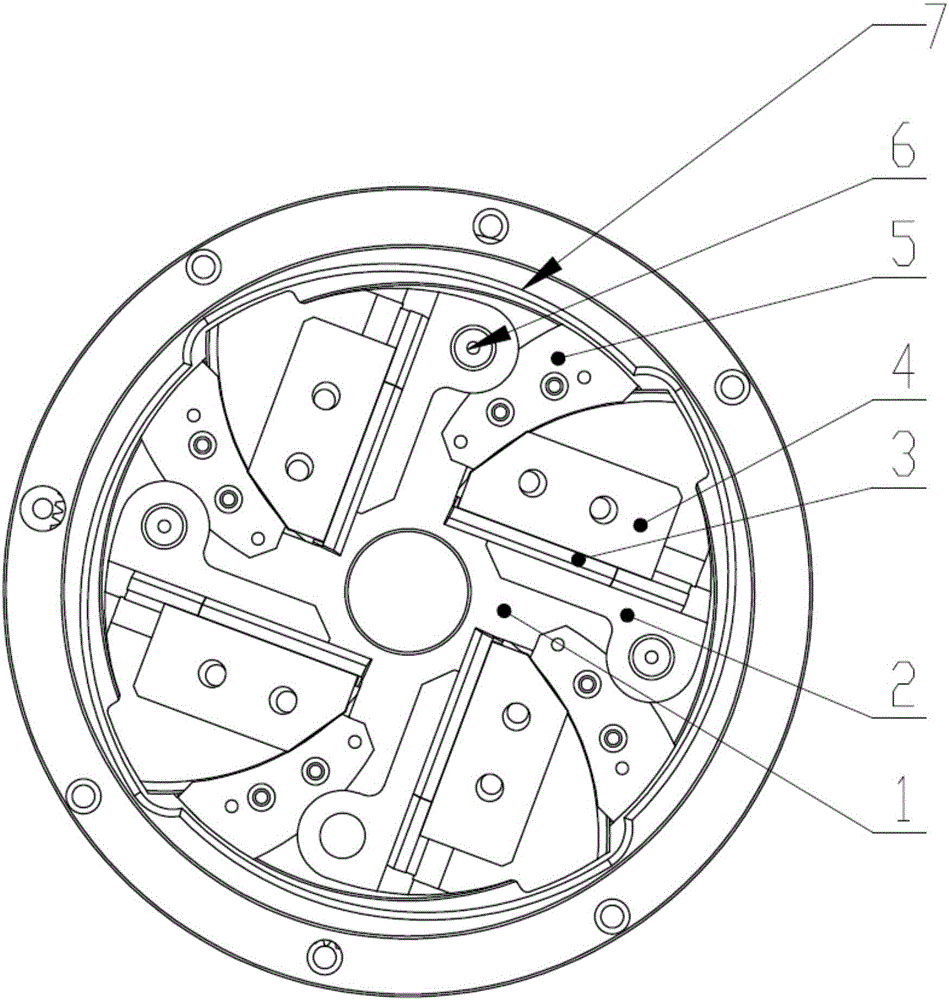

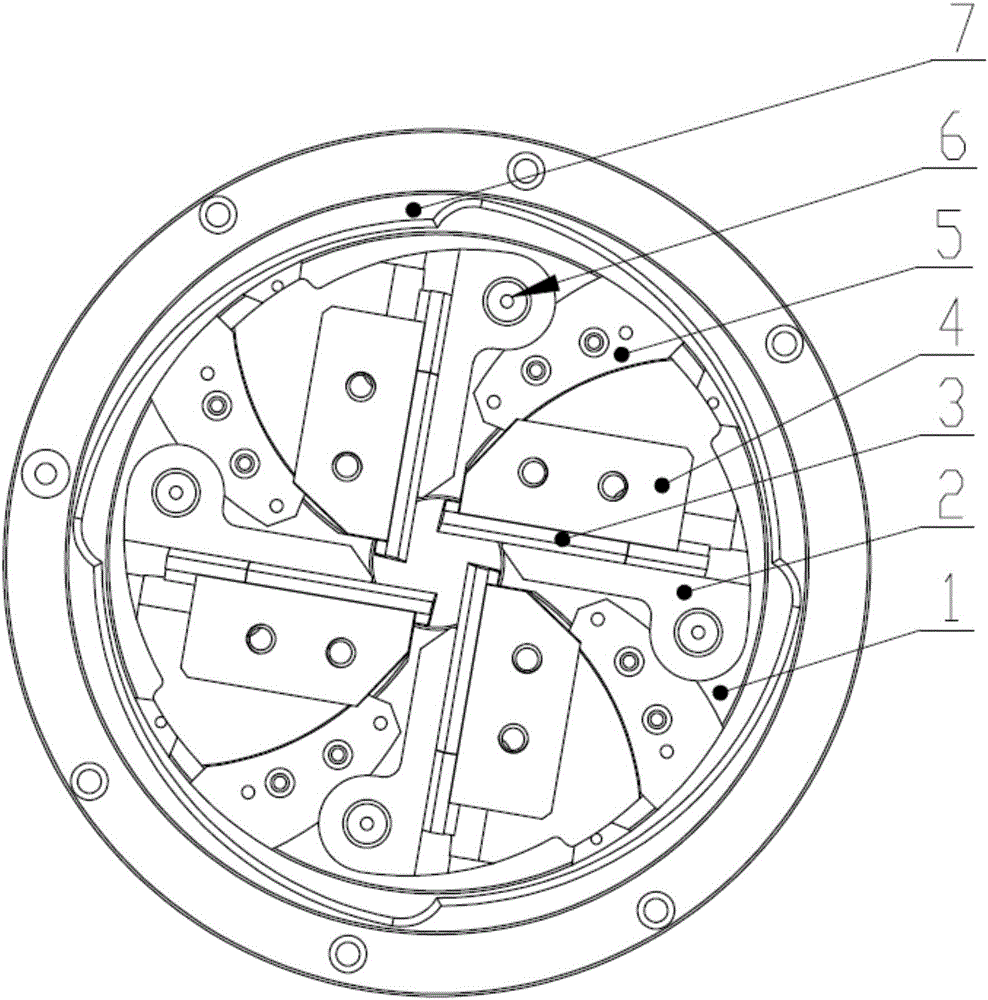

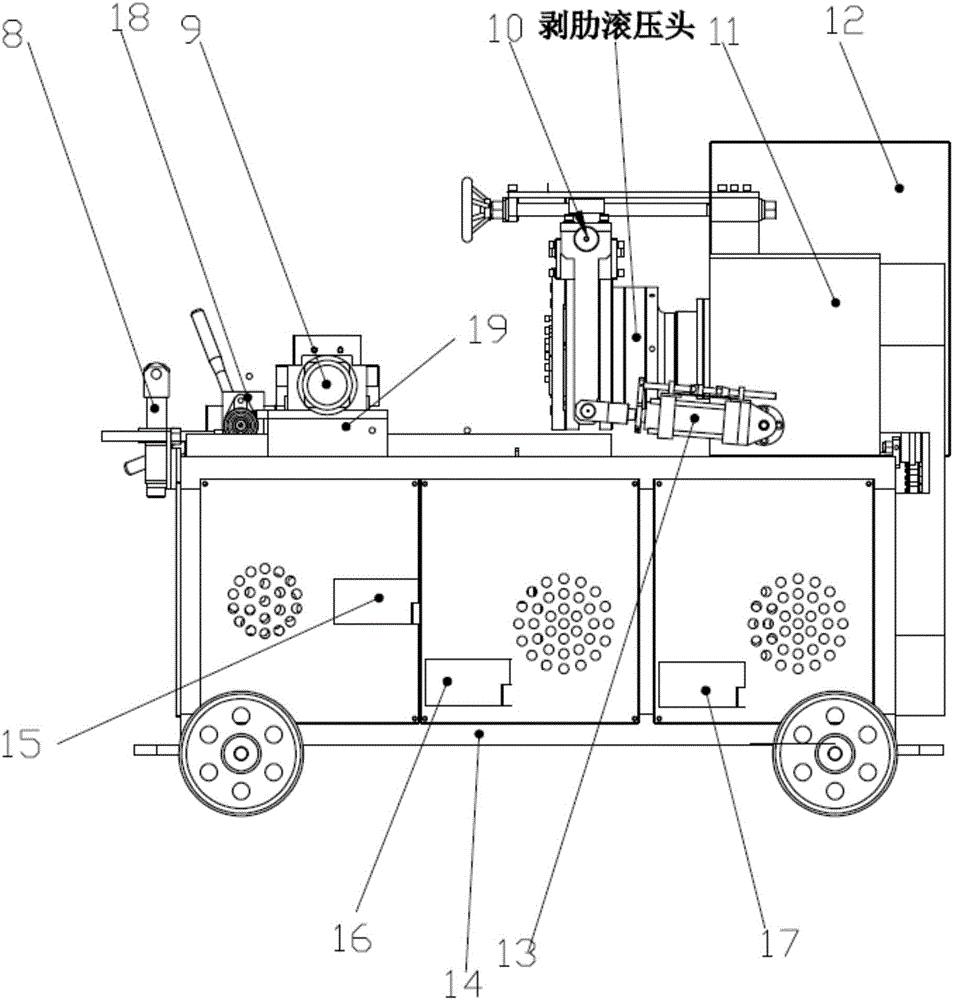

[0012] Such as Figures 1 to 3 As shown, the labels in the figure are: 1. Rib stripping cutter head; 2. Rib stripping knife seat; 3. Rib stripping knife; 4. Pressing knife block; Ring gear; 8. Reinforcement support; 9. Vice slide table; 10. Tool raising mechanism; 11. Spindle box; 12. Electric control box; 13. Hydraulic cylinder; 14. Bed; 15. Hydraulic station; 16. Cooling Liquid tank pump; 17. Motor reducer; 18. Hydraulic vise controlled; 19. Guide rail.

[0013] The rib stripping rolling head of the present invention, the rib stripping rolling head includes a rib stripping cutter head 1, a rib stripping knife seat 2, a rib stripping knife 3, a pressure knife block 4, a knife seat fixing block 5, a rotating shaft 6, an adjustment tooth ring 7; the rib stripping tool holder 2 is arranged on the surface of the rib stripping cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com