Construction concrete mixing tank with double stirring apparatuses

A double-mixing and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, liquid ingredient supply device, etc., can solve the problem of limited mixing area of spiral blade and mixing plate, easy adhesion of concrete on the inner wall of mixing tank, and easy residue of discharge In the middle of the mixing tank, to achieve the effect of easy and efficient mixing, easy to fully contact, expand the spraying area and spraying intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

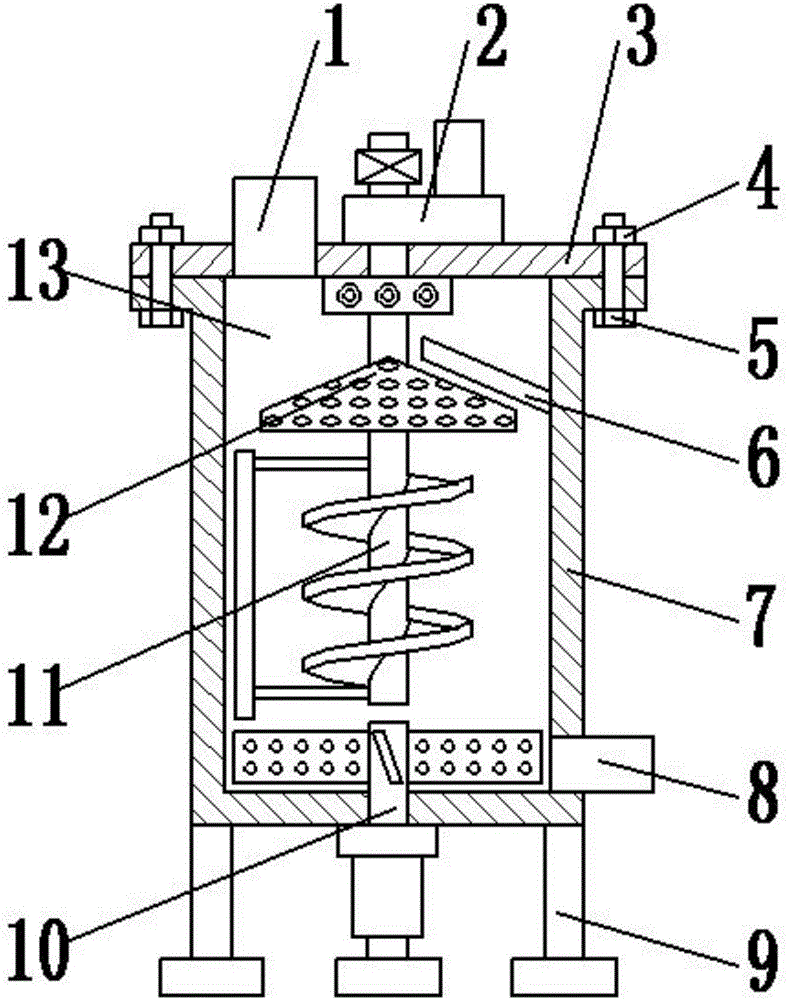

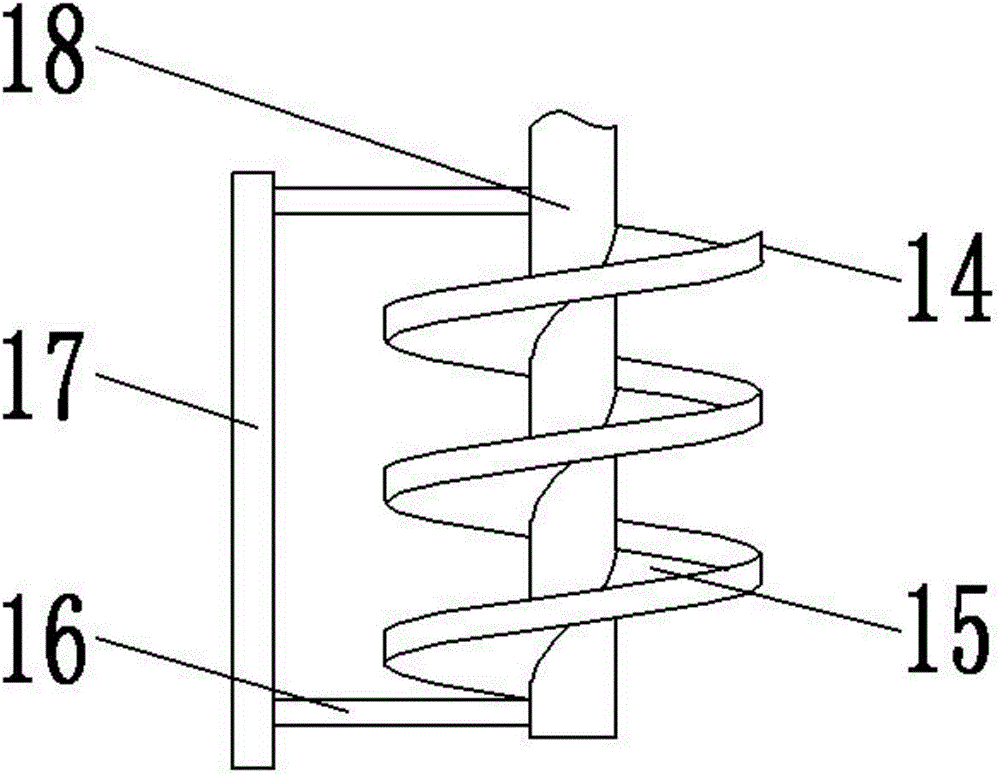

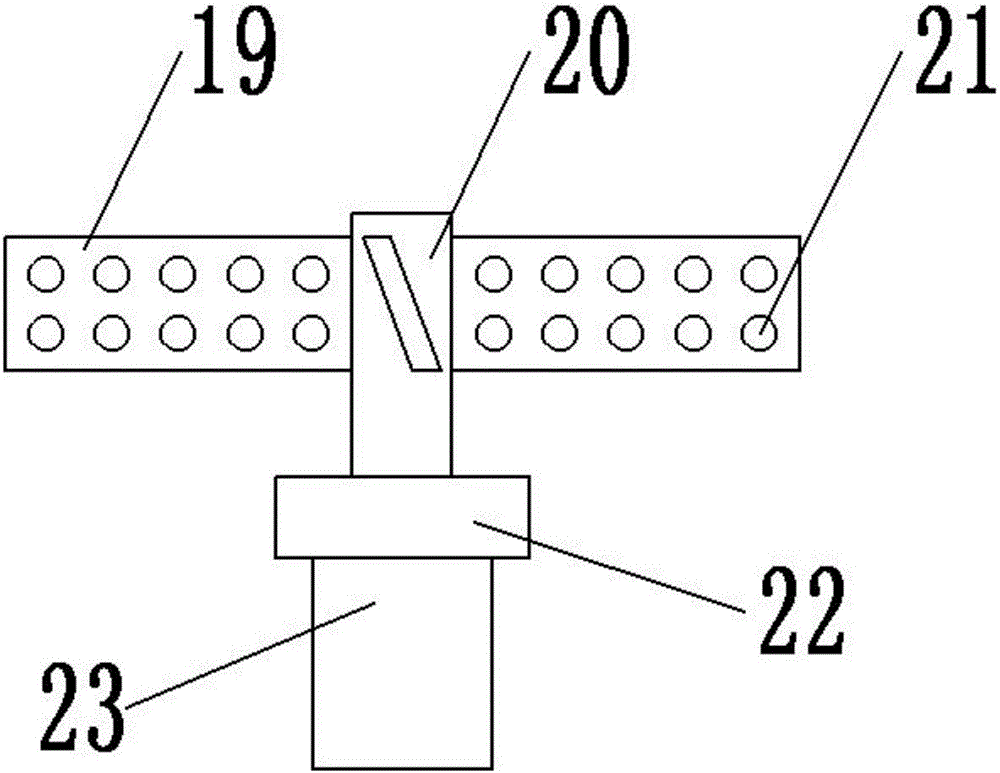

[0019] see Figure 1-4 , a concrete mixing tank for construction with double mixing devices, including a tank body 7; the tank body 7 is set as a hollow cylinder, made of steel, the inside is set as a mixing chamber 13, and the top opening is provided with an upper cover 3; the upper cover 3 is connected with the tank body 7 through the mutual screwing of the bolt 5 and the nut 4, which is convenient for later disassembly for repair and maintenance; the upper cover 3 is provided with a feeding pipe 1 and a water adding and driving device 2; The feed pipe 1 is arranged on the left side of the upper cover 3 for adding concrete ingredients; the water adding and driving device 2 is arranged in the middle of the upper cover 3, and is composed of a transmission box 26, a first motor 25, a water inlet pipe 24 and a rotating spray plate 28; the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com