A kind of aromatic barium mercapto salt, composition and its application as stabilizer in PVC

An aromatic and composition technology, applied in the preparation of organic compounds, carboxylates, carboxylates, etc., can solve the problems of poor stability, affect the colorability and precipitation of PVC films, and achieve good resistance. Oxidation, improving initial coloration and later stability, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

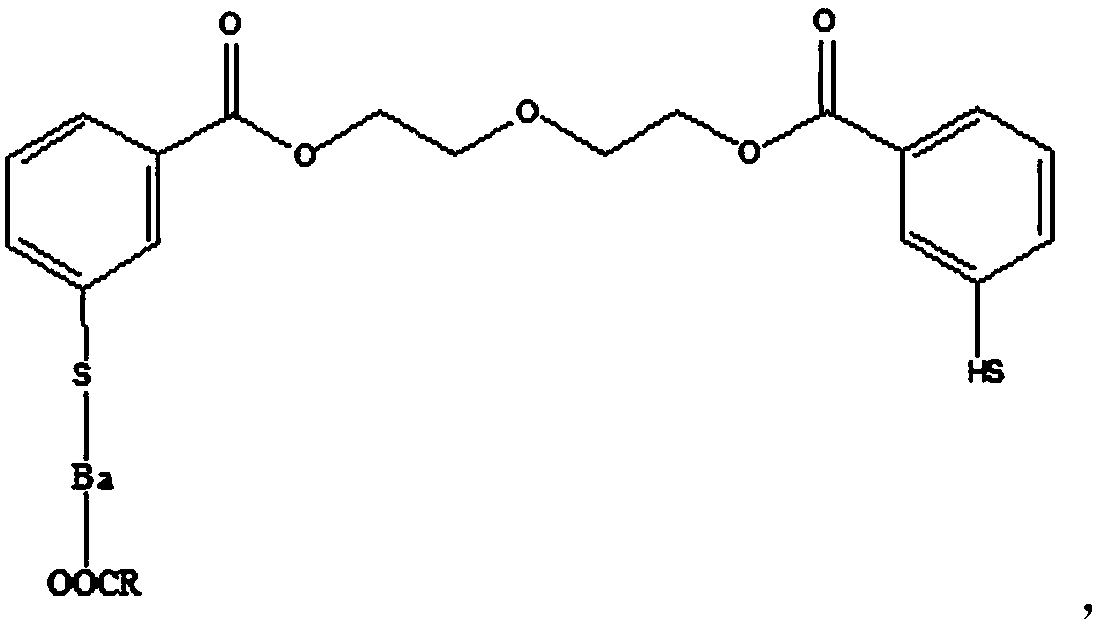

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

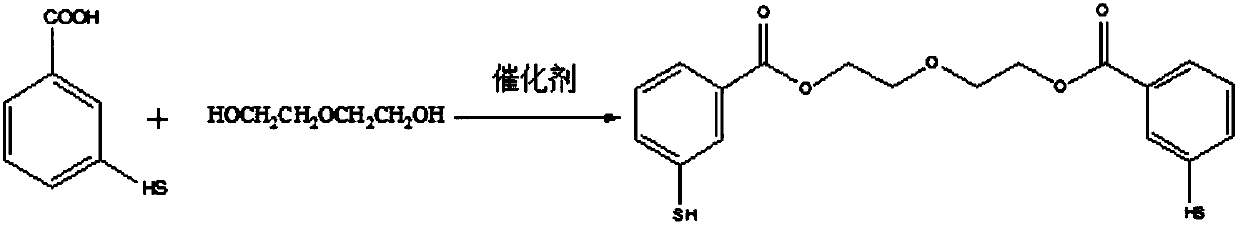

[0039] Put 314g of o-toluic acid, 104g of diethylene glycol, and 1.5g of concentrated sulfuric acid into the reactor, stir, raise the temperature to 110°C, and continue the reaction for 3 hours at a vacuum of -0.06MPa, remove the generated water, and then wash with water. Dehydration obtains dimercaptobenzoic acid ester;

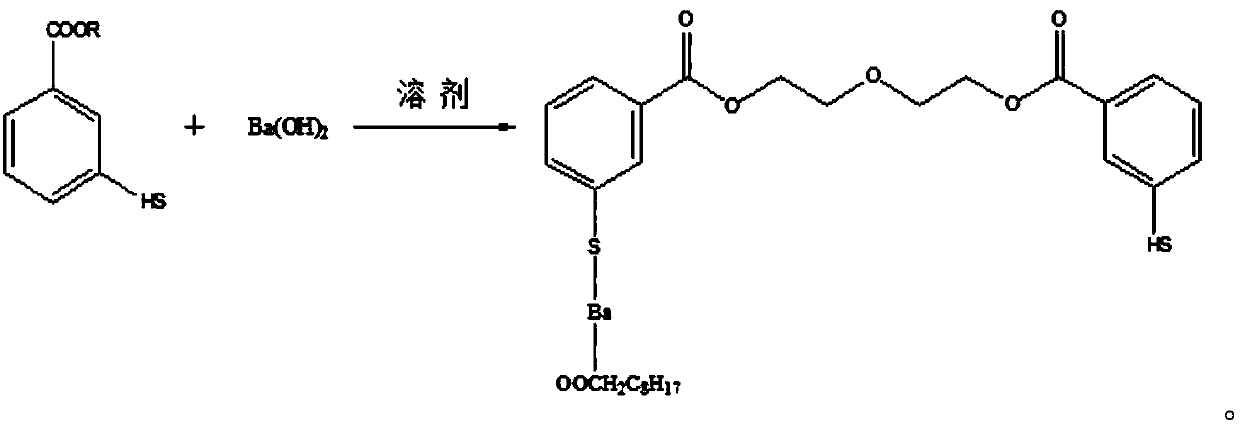

[0040] Mix the intermediate product of the above reaction with 150g of isooctanoic acid and 40g of butanediol methyl ether at 60°C for 40 minutes, add 90g of barium hydroxide, heat up to 110°C, react for 2 hours, dehydrate, and filter to obtain the product aromatic mercapto Barium salt 1#, after determination, the barium content is 10.12%.

Embodiment 2

[0042] Put 283g of p-toluic acid, 93g of diethylene glycol, and 3g of p-toluenesulfonic acid into the reactor, stir, raise the temperature to 115°C, and continue the reaction for 2.5 hours at a vacuum degree of -0.08MPa to remove the generated water. Then wash with water and dehydrate to obtain dimercaptobenzoic acid ester;

[0043] Mix the intermediate product of the above reaction with 163g of n-capric acid and 32g of propylene glycol ethyl ether at 65°C for 45 minutes, add 80g of barium hydroxide, heat up to 105°C, react for 2.5 hours, dehydrate, and filter to obtain the product aromatic mercaptobarium salt 2#, after determination, the barium content is 9.43%.

Embodiment 3

[0045] Put 220g of m-toluic acid, 73g of diethylene glycol, and 1g of sodium bisulfate into the reactor, stir, raise the temperature to 113°C, and continue the reaction for 3.5 hours at a vacuum of -0.07MPa, remove the generated water, and then wash with water. Dehydration obtains dimercaptobenzoic acid ester;

[0046] Mix the intermediate product of the above reaction with 208g of lauric acid and 30g of ethylene glycol butyl ether at 63°C for 50 minutes, add 63g of barium hydroxide, heat up to 107°C, react for 3 hours, dehydrate, and filter to obtain the product aromatic mercapto Barium salt 3#, after determination, the barium content is 9.24%.

[0047] Two, the preparation of aromatic mercapto barium salt composition

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com