Plant oil based polyol as well as preparation method thereof and applications

A vegetable oil-based, polyol-based technology, applied in the direction of organic chemistry, can solve the problems of waste of raw materials, environmental pollution, loss, etc., and achieve the effect of simple preparation process, no need for follow-up treatment, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

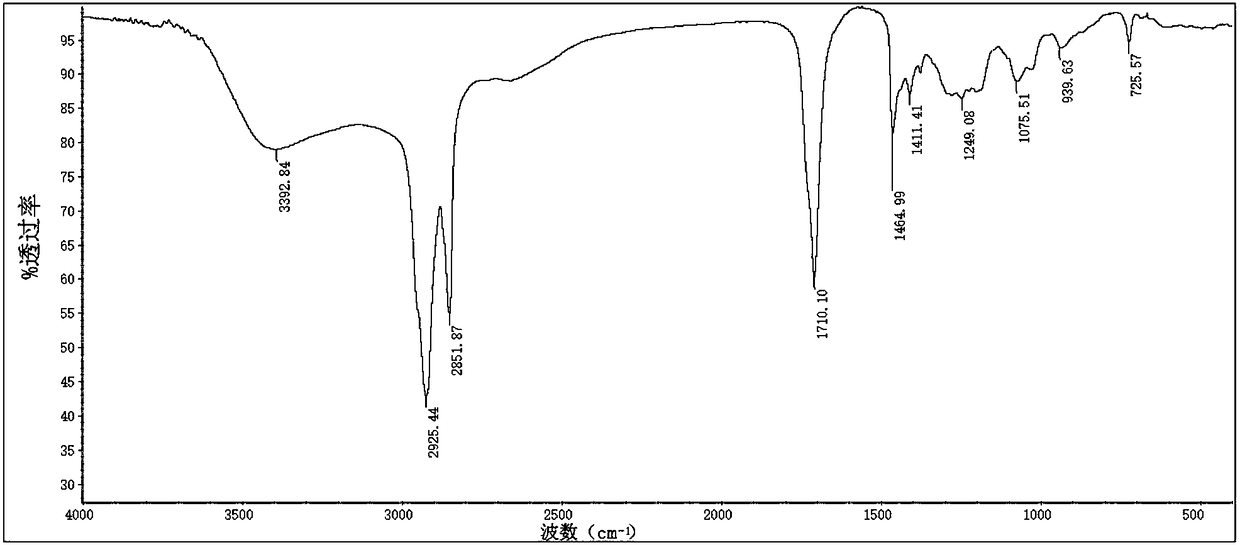

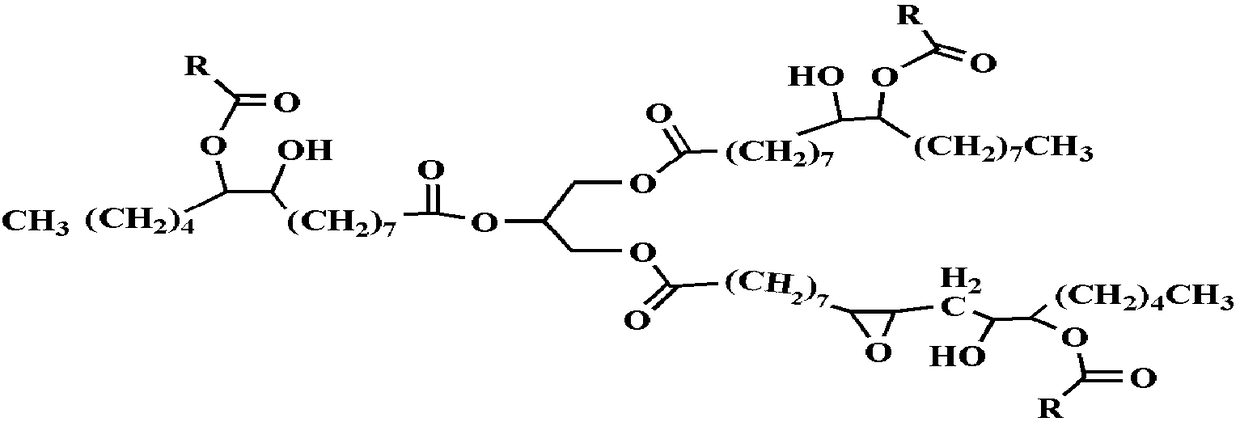

[0040] Weigh 50 g of epoxidized soybean oil (epoxy value 0.425mol / 100g) into a 250ml three-necked bottle, install stirring and a thermometer and ventilate nitrogen, heat to 90°C in an oil bath, and start adding dropwise to the epoxidized soybean oil Concentration is 15% sodium hydroxide solution 33.3g, dropwise is finished within 2h, after continuing to stir and react for 0.5h, then add concentration is 36% hydrochloric acid solution 13.8g to it, after continuing to stir and react for 1.5h, all Transfer to a 250ml pear-shaped separatory funnel for liquid separation to take the oil phase, and wash with deionized water to neutrality, then distill under reduced pressure to obtain 41.0 g of single-chain fatty acids. The acid value of the single-chain fatty acid was determined to be 162.40 mgKOH / g. Infrared spectrum test for single-chain fatty acids, the results are as follows figure 1 shown. Depend on figure 1 It can be seen that 1710.10cm -1 It is the characteristic absorptio...

Embodiment 2

[0043] Weigh 50g of epoxidized soybean oil (epoxy value 0.425mol / 100g) into a 250ml three-necked bottle, install stirring and a thermometer and pass nitrogen, heat to 95°C in an oil bath, and start to dropwise add Concentration is 33.3g of sodium hydroxide solution of 15%, dropwise is finished within 2h, after continuing to stir and react for 1.0h, then add concentration is 36% hydrochloric acid solution 13.8g to it, after continuing to stir and react for 1.5h, all Transfer to a 250ml pear-shaped separatory funnel for liquid separation to take the oil phase, and wash with deionized water to neutrality, then distill under reduced pressure to obtain 42.3g of single-chain fatty acids. The acid value of the single-chain fatty acid was determined to be 157.0 mgKOH / g.

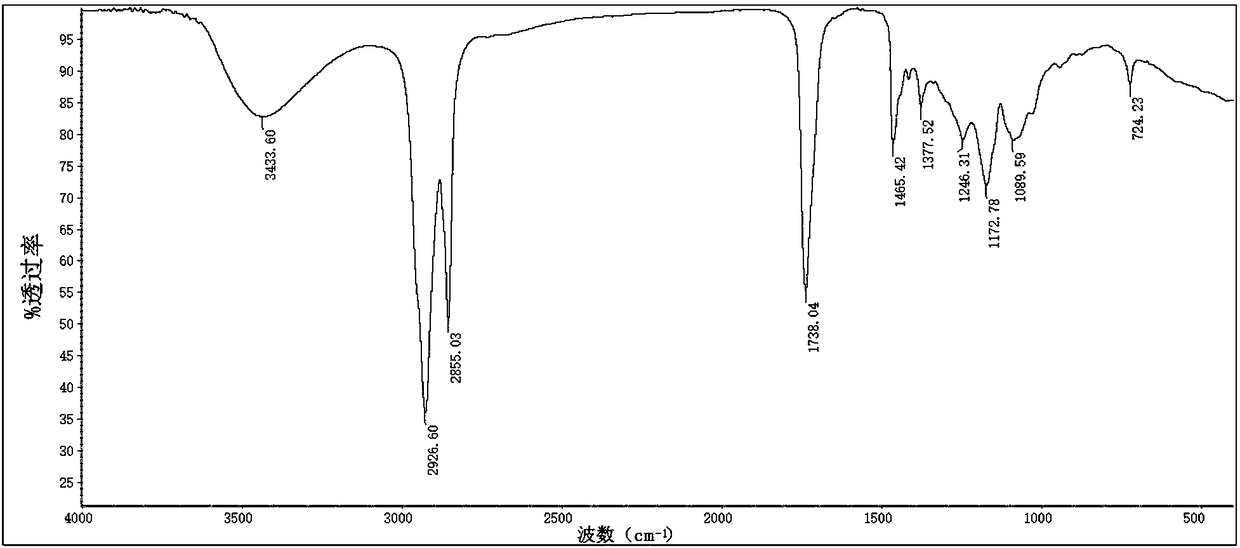

[0044] Take above-mentioned single-chain fatty acid 35.0g and epoxidized soybean oil (epoxy value 0.425mol / 100g) 46.2g in the 250ml there-necked flask, then add catalyst tetrabutylammonium bromide 0.5g wherein, under...

Embodiment 3

[0046] Weigh 50g of epoxidized soybean oil (epoxy value 0.425mol / 100g) into a 250ml three-necked bottle, install stirring and a thermometer and pass nitrogen, heat to 95°C in an oil bath, and start to dropwise add Concentration is 10% potassium hydroxide solution 75.95g, dropwise is completed within 2h, after continuing to stir and react for 0.5h, then add concentration is 36% hydrochloric acid solution 13.8g to it, after continuing to stir and react for 1.5h, all Transfer to a 250ml pear-shaped separatory funnel for liquid separation to get the oil phase, and wash with deionized water to neutrality, then distill under reduced pressure to obtain 40.6g of single-chain fatty acids. The acid value of the single-chain fatty acid was determined to be 156.3 mgKOH / g.

[0047] Take above-mentioned single-chain fatty acid 35.0g and epoxidized soybean oil (epoxy value 0.425mol / 100g) 25.7g in the 250ml there-necked bottle, then add catalyst tetrabutylammonium bromide 0.2g wherein, under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com