Methyl tin reverse thioester and preparation method thereof

A technology of methyl tin and reverse thioester, applied in the direction of tin organic compounds, etc., can solve problems such as insufficient lubricity, and achieve the effects of improving initial coloration, delaying PVC degradation, and improving lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

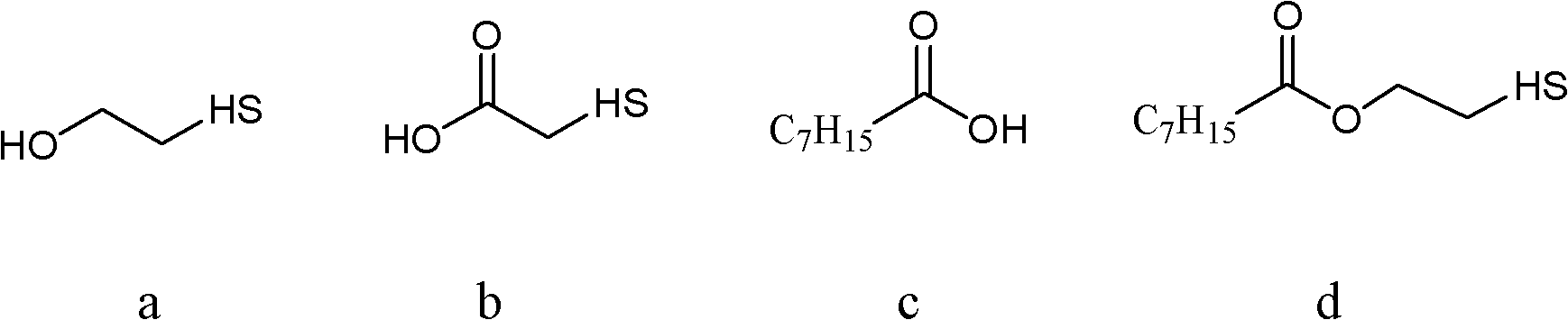

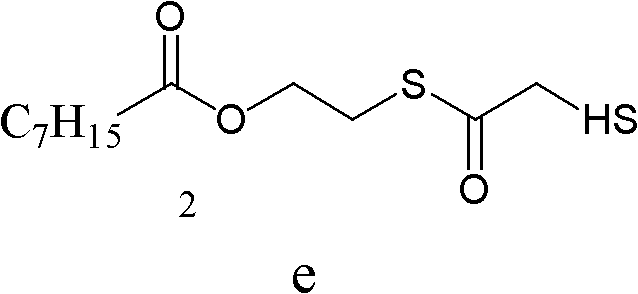

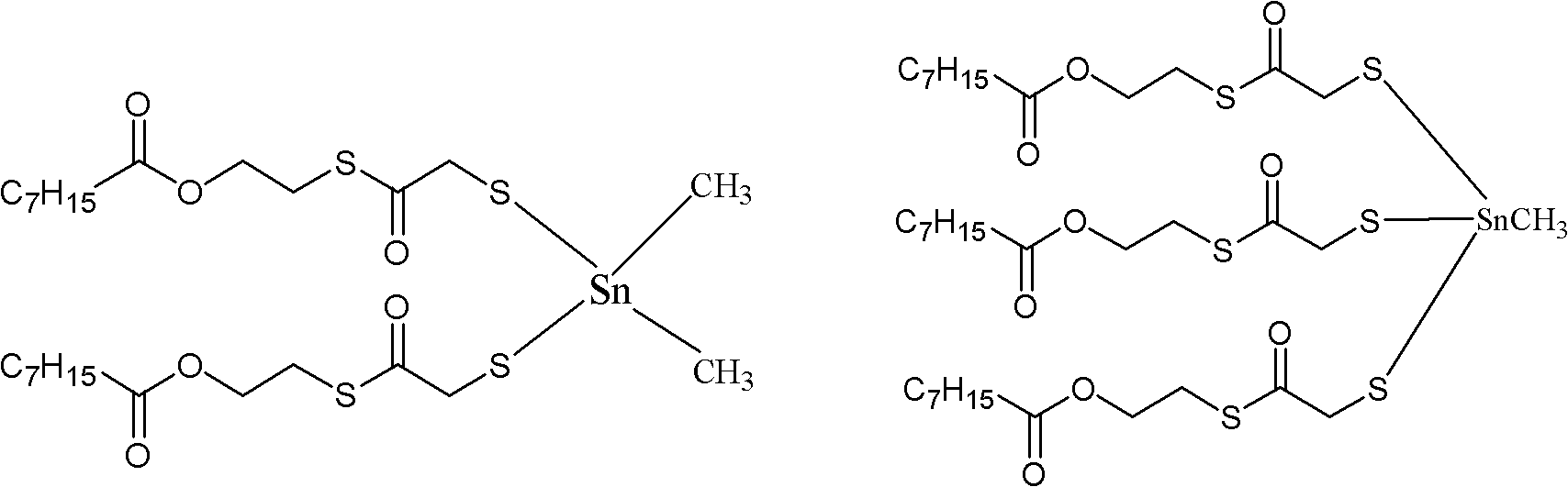

Method used

Image

Examples

Embodiment 1

[0038] 147g of isooctanoic acid, 78g of mercaptoethanol and 140g of hexanaphthene were mixed in a three-necked flask equipped with a thermometer, a stirrer and a reflux device, stirred, heated to 120°C, the reactant began to reflux, and slowly added dropwise 6g of vitriol oil (98.5 wt%), close the separatory funnel after the dropwise addition, reflux until there are no more drops of water hanging on the inner wall of the distillation column, cool to room temperature, then heat to about 80°C to distill off the solvent to obtain 204.2g of mercaptoethyl isooctanoate ;

[0039] In a three-necked flask equipped with a thermometer, a stirrer and a vacuum reflux device, 204.2 g of mercaptoethyl isooctanoate, 6 g of concentrated sulfuric acid (98.5 wt %) and 95 g of mercaptoacetic acid obtained above were mixed, stirred, heated to 70 ° C, and kept The vacuum degree is -0.062~-0.074MPa, react for 2 hours, no more water drips out of the water separator, cool to room temperature, wash wi...

Embodiment 2

[0044] Mix 150g of isooctanoic acid, 79.6g of mercaptoethanol and 150g of xylene in a three-necked flask equipped with a thermometer, a stirrer and a reflux device, stir, heat to 125°C, the reactant starts to reflux, and slowly add 8g of p-toluene dropwise Sulfonic acid, after the dropwise addition, close the separatory funnel, reflux until no more water droplets hang on the inner wall of the distillation column, cool to room temperature, and distill off the solvent at about 140°C to obtain 208.1 g of mercaptoethyl isooctanoate;

[0045] Mix 208.1g of mercaptoethyl isooctanoate, 8g of p-toluenesulfonic acid and 96g of mercaptoacetic acid in a three-neck flask equipped with a thermometer, a stirrer and a reflux device, stir, heat to 90°C, and maintain a vacuum of -0.068 ~-0.079MPa, reacted for 2.5 hours, no more water dripped out of the water separator, cooled to room temperature, washed with water, took out the oil phase, and distilled and dehydrated under reduced pressure to o...

Embodiment 3

[0051] 156g of isooctanoic acid, 81.9g of mercaptoethanol and 160g of ether were mixed in a three-necked flask equipped with a thermometer, a stirrer and a reflux device, stirred, heated to 130°C, the reactant began to reflux, and 10g of butyl titanate was slowly added dropwise, After the dropwise addition, close the separatory funnel, reflux until no more water droplets hang on the inner wall of the distillation column, cool to room temperature, and distill off the solvent at about 35°C to obtain 214.2 g of mercaptoethyl isooctanoate;

[0052] Mix 214.2g of mercaptoethyl isooctanoate, 100g of mercaptoacetic acid and 12g of butyl titanate in a three-necked flask equipped with a thermometer, a stirrer and a reflux device, stir, heat to 110°C, and keep the vacuum at -0.075~- 0.90MPa, reacted for 3 hours, no more water dripped out of the water separator, cooled to room temperature, washed with water, took out the oil phase, and dehydrated by distillation under reduced pressure to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com