A kind of mixed anionic zinc monomer and its composition and application

An anion and composition technology, applied in the direction of zinc organic compounds, etc., can solve the problems of less research on calcium and zinc stabilizers, and achieve good anti-oxidation, improved thermal stability, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

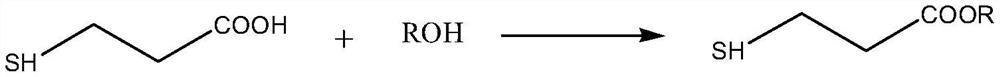

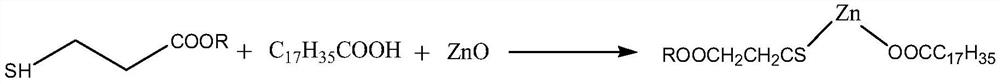

Method used

Image

Examples

Embodiment 1

[0029] Put 106g of mercaptopropionic acid, 186g of lauryl alcohol, and 2g of sodium bisulfate into the reactor, stir, heat up to 112°C, and continue to react for 3 hours at a vacuum of -0.06MPa, remove the generated water, and then wash to remove sodium bisulfate. Dehydration to obtain 274g of lauryl mercaptopropionate; mix the above reaction product with 284g of stearic acid for 30 minutes, put in 40g of zinc oxide and keep it warm at 105°C for 2.5 hours, dehydrate and dry to obtain 1# zinc monomer. After determination, the zinc content is 5.1 %.

Embodiment 2

[0031] Put 106g of mercaptopropionic acid, 214g of palmitic alcohol, and 2g of sodium bisulfate into the reactor, stir, heat up to 115°C, and continue to react for 3 hours at a vacuum of -0.06MPa, remove the generated water, and then wash to remove sodium bisulfate. Dehydration to obtain 302g of lauryl mercaptopropionate; mix the above reaction product with 284g of stearic acid for 30 minutes, put in 40g of zinc oxide and keep it warm at 105°C for 2.5 hours, dehydrate and dry to obtain 2# zinc monomer. After determination, the zinc content is 4.9 %.

[0032] 2. Preparation of compositions containing mixed anionic zinc monomers

Embodiment 3

[0034] A composition containing mixed anion zinc monomer, said composition is processed by the following components: 1# zinc monomer 15g, trioctadecyl phosphite 20g, antioxidant tetrakis[methyl - 5 g of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 2 g of dibenzoylmethane, and 40 g of magnesium aluminum hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com