Method of producing high-performance modified asphalt by utilizing mineral powder recovered by asphalt mixing station as well as pyrolytic oil and rubber powder of waste tyre and product of method

A technology of asphalt mixing and modified asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as low calorific value and serious emissions, and achieve the effects of improving use conditions, protecting the environment, and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

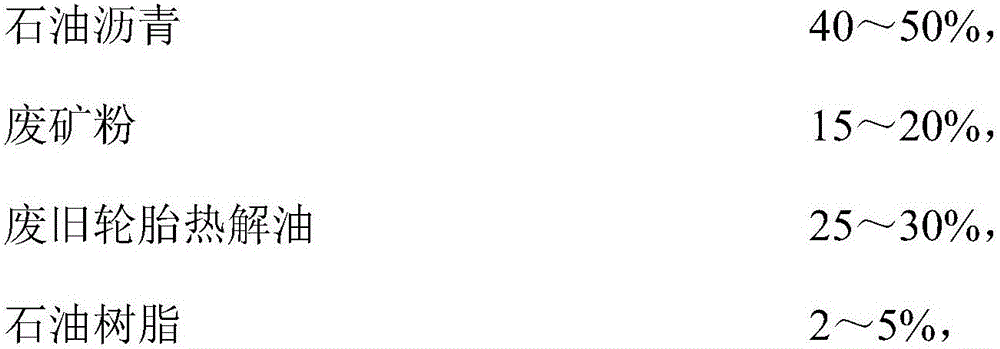

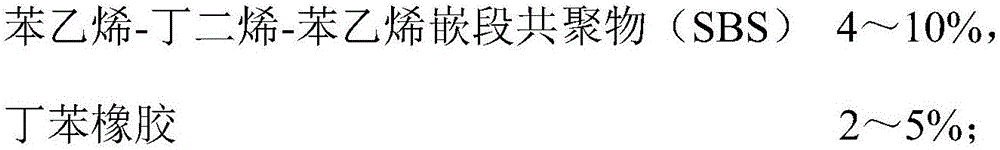

[0023] Embodiment 1: A method for producing high-performance modified asphalt by using asphalt mixing plant to recover mineral powder and waste tire pyrolysis oil and rubber powder provided in this embodiment includes the following steps:

[0024] (1) Preparing raw materials: the components and weight percentages of the raw materials are as follows: 40% of petroleum asphalt, 15% of waste mineral powder, 30% of waste tire pyrolysis oil, 5% of petroleum resin, styrene-butadiene-styrene embedded Segment copolymer (SBS) 5%, styrene-butadiene rubber 5%;

[0025] (2) Heating and mixing: heat the waste tire pyrolysis oil to above 140-160°C, then gradually add styrene-butadiene rubber into the waste tire pyrolysis oil, and then add styrene-butadiene-styrene block copolymer , and constantly heating and stirring; preferably, in the step (2), the styrene-butadiene-styrene block copolymer is added after the styrene-butadiene rubber is completely dissolved.

[0026] (3) When the heating t...

Embodiment 2

[0031] Example 2, this example provides a method for producing high-performance modified asphalt and its products by using asphalt mixing plant to recover mineral powder, waste tire pyrolysis oil and rubber powder, and its components and production steps are basically the same as those in Example 1. The same, the difference is that the components of the raw materials and their weight percentages are as follows: petroleum asphalt 50%, waste mineral powder 15%, waste tire pyrolysis oil 25%, petroleum resin 2%, styrene-butadiene- Styrene block copolymer (SBS) 4%, styrene-butadiene rubber 4%.

[0032] The indicators of the high-performance modified asphalt products produced by the above-mentioned method of producing high-performance modified asphalt by using the asphalt mixing plant to recover mineral powder, waste tire pyrolysis oil and rubber powder are as follows:

[0033] project unit test results experiment method Penetration 25℃ 0.1mm 99.6 T0604 ...

Embodiment 3

[0034] Example 3, this example provides a method for producing high-performance modified asphalt and its products by using asphalt mixing plant to recover mineral powder, waste tire pyrolysis oil and rubber powder, and its components and production steps are basically the same as those in Example 1. The same, but the difference is that the components of the raw materials and their weight percentages are as follows: 45% of petroleum asphalt, 16% of waste mineral powder, 26% of waste tire pyrolysis oil, 4% of petroleum resin, styrene-butadiene- Styrene block copolymer (SBS) 7%, styrene-butadiene rubber 2%.

[0035] The indicators of the high-performance modified asphalt products produced by the above-mentioned method of producing high-performance modified asphalt by using the asphalt mixing plant to recover mineral powder, waste tire pyrolysis oil and rubber powder are as follows:

[0036] project unit test results experiment method Penetration 25℃ 0.1mm 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com