Preparing method for medium-chromium-based ferritic stainless steel low power structure

A technology of low-magnification microstructure and stainless steel, which is applied in the preparation of test samples, etc., can solve the problems of unstable corrosion effect of ferritic stainless steel, no method of ferritic stainless steel corrosion, and difficulty in effectively observing low-magnification microstructure. The crystal grains are clearly visible, avoiding intergranular corrosion, and inhibiting the effect of intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

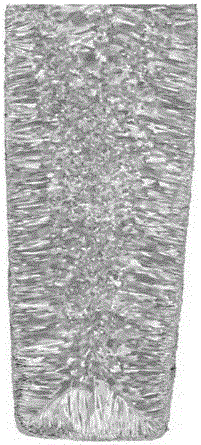

[0048] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a medium-chromium-based ferritic stainless steel etchant of this embodiment is used for the preparation process of the low-magnification solidification structure of medium-chromium-based ferritic stainless steel, and the chromium of medium-chromium-based ferritic stainless steel The content is 16%-18%, and the etching agent is composed of ethanol, nitric acid, hydrochloric acid and distilled water, and the volume ratio of ethanol: nitric acid: hydrochloric acid: distilled water is 1:1:2:2, that is, the volume fraction of each component It is: 50 parts of ethanol, 50 parts of nitric acid, 100 parts of hydrochloric acid, and 100 parts of distilled water. Wherein: ethanol, nitric acid, and hydrochloric acid are all analytically pure, that is, the concentration of ethanol is 95%, the concentration of nitric acid is 65%, and the concentration of hydrochloric acid is 36%.

[0049] In this embodiment, taking ...

Embodiment 2

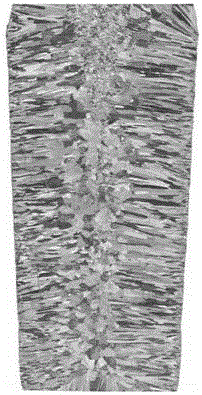

[0080] The basic content of this embodiment is the same as that of Embodiment 1, except that: the slab of medium chromium-based ferritic stainless steel 439 stainless steel is taken as an example, and the 439 stainless steel is etched, wherein the chromium content is 17.90%. The slab is wide, and its "width x thickness" is "1250 mm x 200 mm". Since the board is wider, the board is divided into three sections, and this embodiment is one of the three sections of the board.

[0081] The etching agent includes: ethanol, nitric acid, hydrochloric acid and distilled water, and the parts by volume of each component are: 25 parts of ethanol, 25 parts of nitric acid, 50 parts of hydrochloric acid, and 50 parts of distilled water.

[0082] A method for preparing a low-magnification structure of a medium-chromium-based ferritic stainless steel in this embodiment comprises the following steps:

[0083] Step 1. Preparation of etchant

[0084] (1) Preparation of nitric acid ethanol mixed ...

Embodiment 3

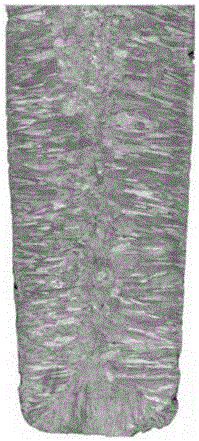

[0100] The basic content of this embodiment is the same as that of Example 1, except that the etching agent includes: ethanol, nitric acid, hydrochloric acid and distilled water, and the parts by volume of each component are: 10 parts of ethanol, 20 parts of nitric acid, and 20 parts of hydrochloric acid. 50 parts, 50 parts of distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com