A control method and system for a variable nozzle supercharger

A control method and supercharger technology, which are applied in the directions of machines/engines, engine components, gas turbine devices, etc., can solve the problems of variable nozzle supercharger overspeed risk, inability to effectively control supercharger response, etc., to avoid overspeed risk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

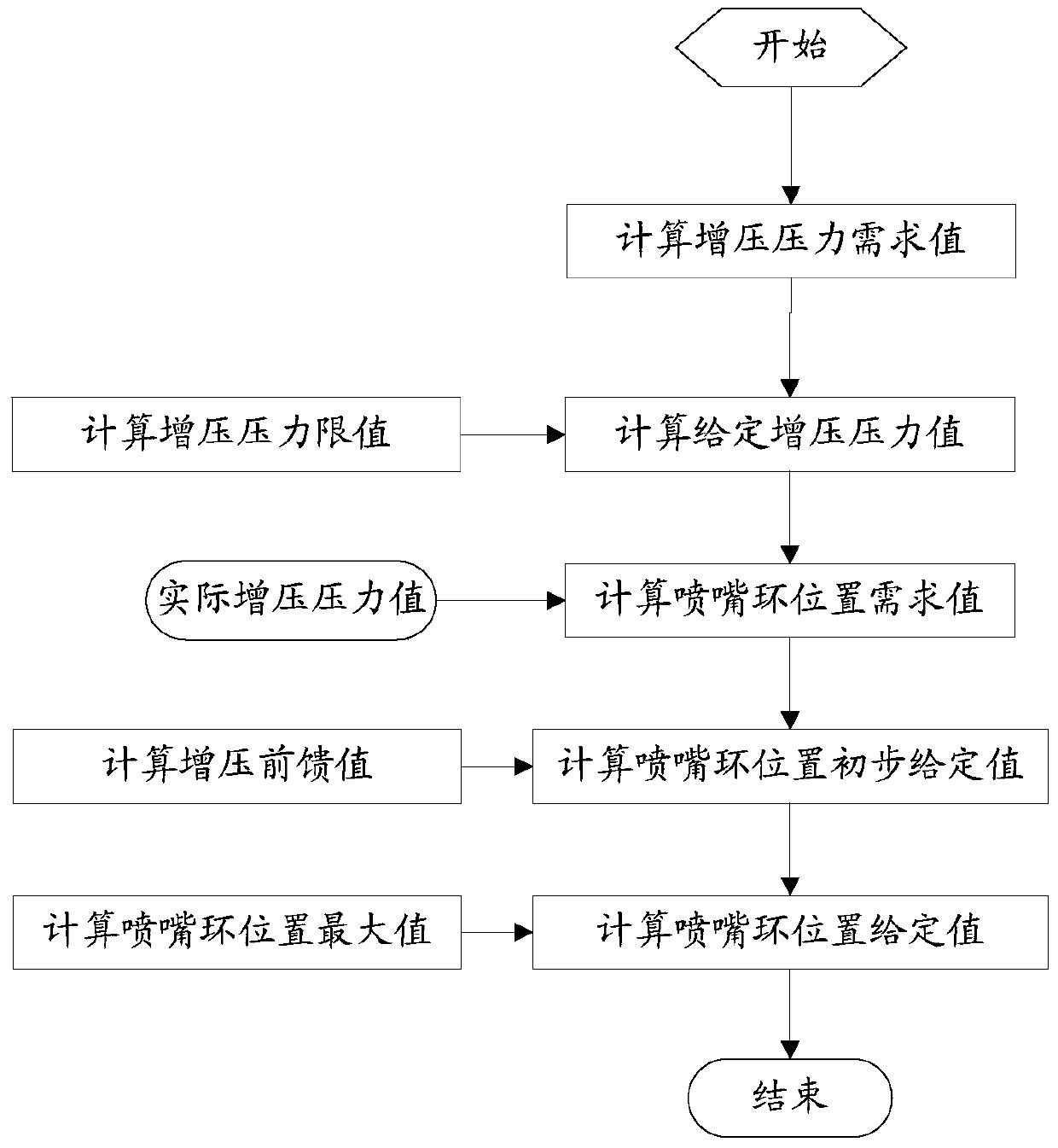

[0049] figure 1 It is a flow chart of a control method of a variable nozzle supercharger provided by the embodiment of the present application.

[0050] Such as figure 1 As shown, the control method of the variable nozzle supercharger provided in this embodiment includes the following steps:

[0051] S101: Calculate a boost pressure demand value.

[0052] According to the obtained engine speed and engine torque of the engine, the engine torque is the output torque of the engine, using the engine speed and engine torque to search on the corresponding first basic map, so as to obtain the boost pressure demand required by the engine value.

[0053] S102: Calculate a boost pressure limit.

[0054] According to the corrected intake air flow and the intake air temperature of the engine calculated by the electronic control unit of the engine according to the current power and other parameters, use the corrected intake air flow and intake air temperature in the second basic map co...

Embodiment 2

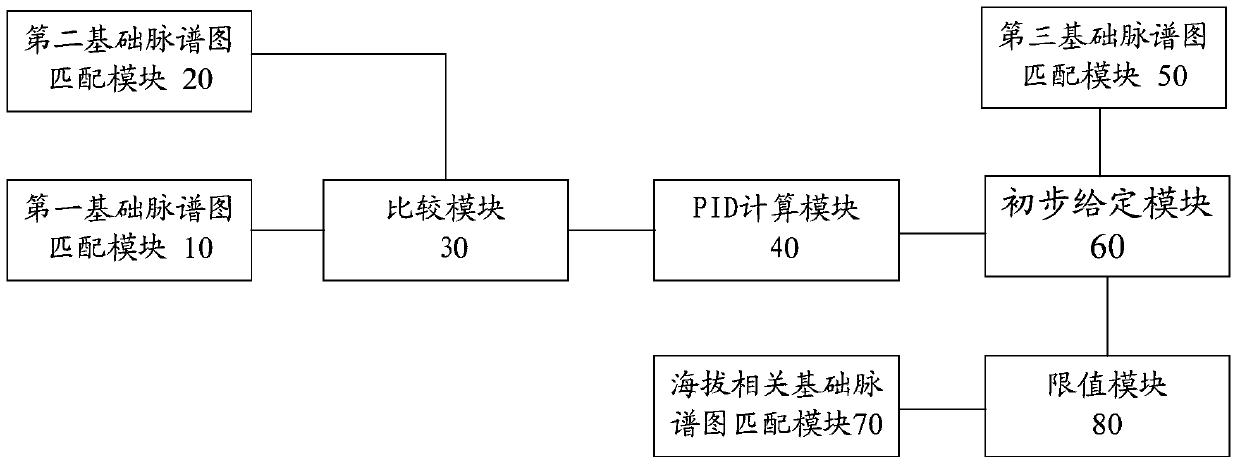

[0071] figure 2 It is a schematic diagram of a control system of a variable nozzle supercharger provided by another embodiment of the present application.

[0072] Such as figure 2 As shown, the control system of the variable nozzle supercharger provided in this embodiment includes a first basic map matching module 10, a second basic map matching module 20, a comparison module 30, a PID calculation module 40, a third basic A map matching module 50 , a preliminary setting module 60 , an altitude-related basic map matching module 70 and a limit value module 80 .

[0073] The first basic map matching module 10 is used to calculate a boost pressure demand value.

[0074] That is, according to the obtained engine speed and engine torque of the engine, a search is performed on the corresponding first basic map, so as to obtain the boost pressure demand value required by the engine.

[0075] The second base map matching module 20 is used to calculate a boost pressure limit.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com