Copper-ring water-cooling type magnetic liquid sealing device

A magnetic liquid and sealing device technology, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve the problems of shortened life of magnetic liquid seals, high heat generation in sealing gaps, high ambient temperature, etc., and achieve high cooling efficiency, fast and efficient Effect of cooling and enhancing pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described with accompanying drawing as specific embodiment:

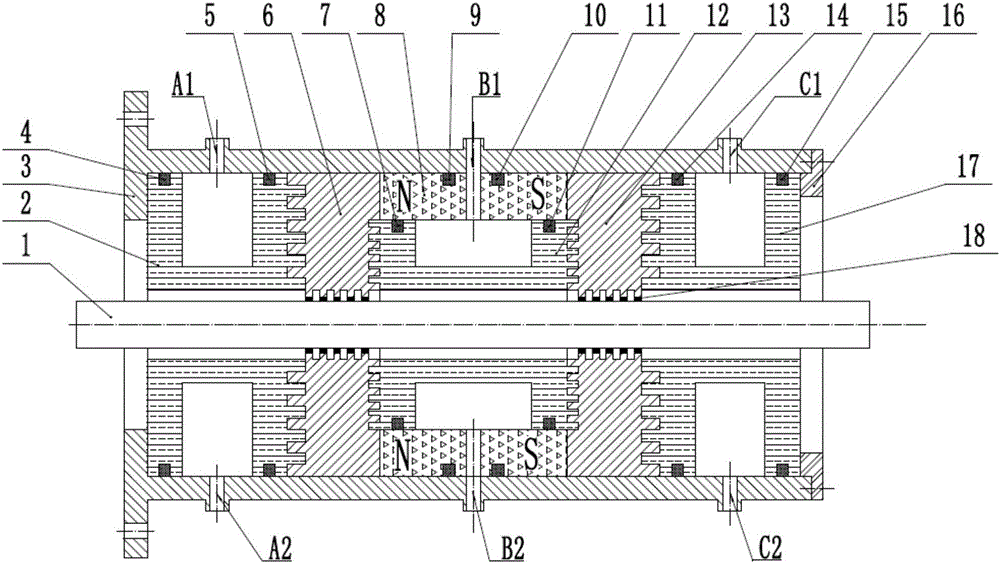

[0014] Copper ring water-cooled magnetic liquid sealing device such as figure 1 : rotary shaft 1, left copper ring 2, shell 3, first sealing ring of left copper ring 4, second sealing ring of left copper ring 5, left pole shoe 6, first sealing ring of middle copper ring 7, permanent magnet 8, permanent Magnet first sealing ring 9, permanent magnet second sealing ring 10, middle copper ring second sealing ring 11, middle copper ring 12, right pole shoe 13, right copper ring first sealing ring 14, right copper ring second sealing ring 15. Right end cap 16, right copper ring 17, magnetic liquid 18.

[0015] The connection between the parts constituting the device: the first sealing ring 4 of the left copper ring and the second sealing ring 5 of the left copper ring are installed in the groove of the outer circle of the left copper ring 2, forming a left copper ring with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com