Clean combustion heating stove for civil use

A technology for clean combustion and heating stoves, which is used in household stoves/stoves, stoves/stoves with hot water devices, applications, etc. It can solve problems such as pollution emissions, improve heat conversion efficiency, and reduce combustibles and pollutants. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

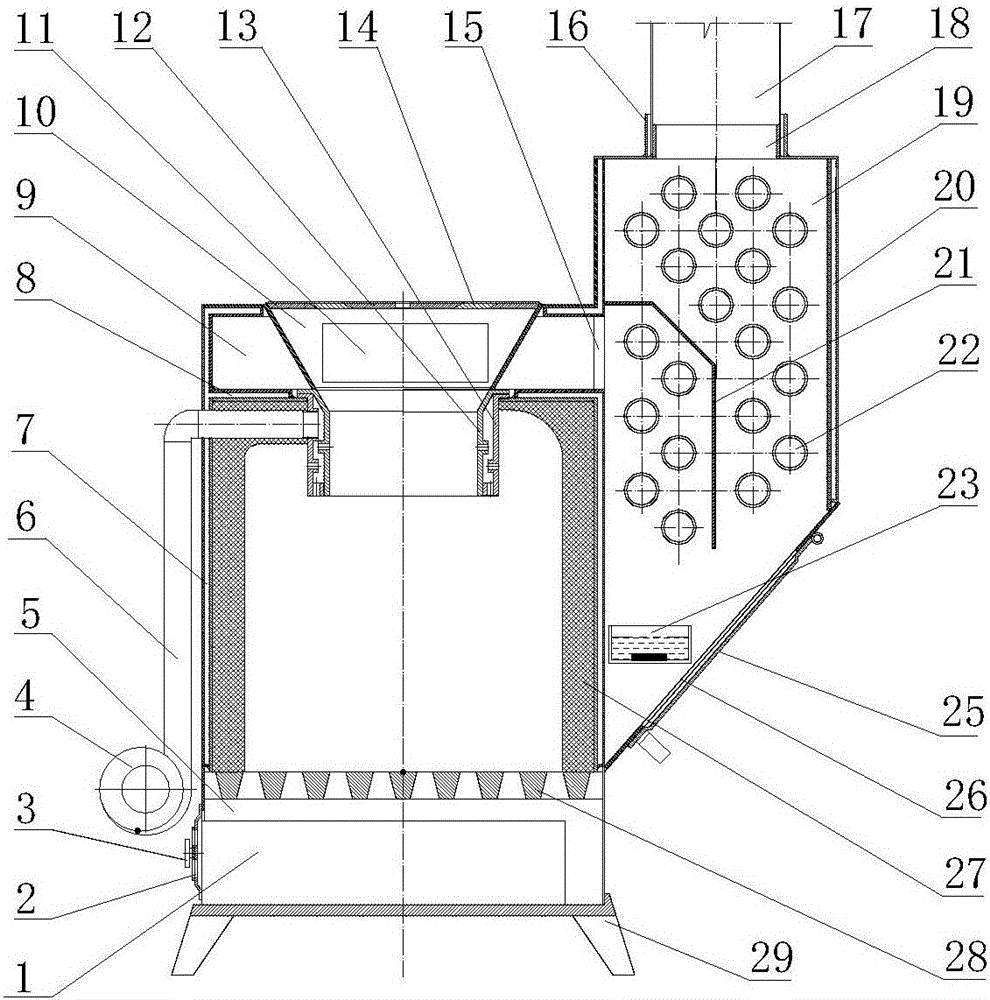

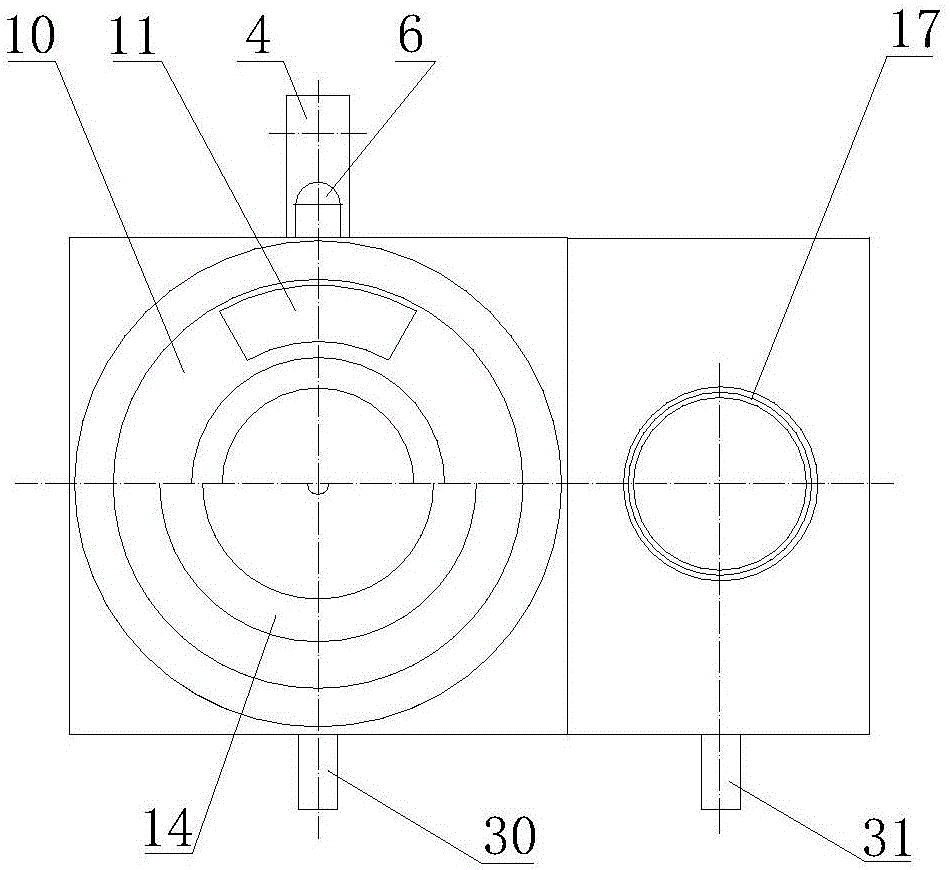

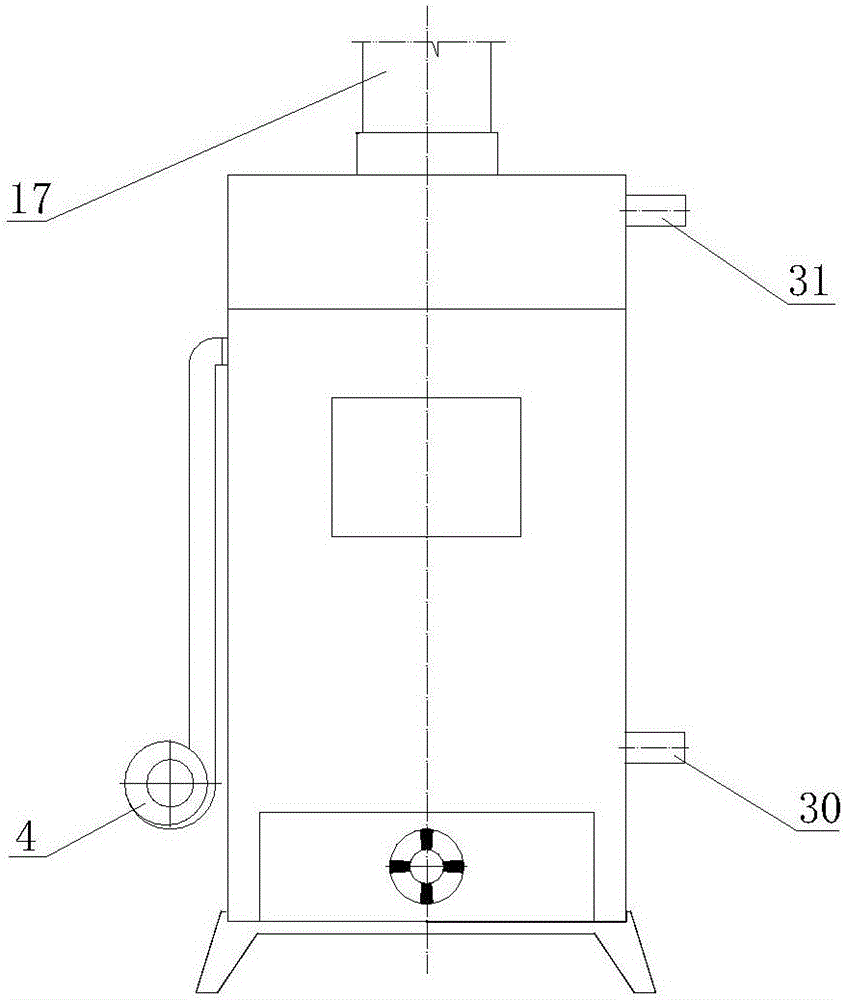

[0033] Figure 1-4 The civil heating furnace shown in the present invention comprises a furnace 5, a fire grate 28, an ash hopper 1, a primary air inlet 2 and a chimney 17, a waste heat recovery box 19 is arranged on the chimney, and a plane water exchange jacket 8 is arranged on the furnace 5 top, The innovation point is to set a cylindrical air supply cavity 13-3 composed of the inner air ring 12, the outer air ring 13 and the lower end surface at the center below the plane water exchange jacket 8, the outer air ring 13 and the inner air ring 12 Outer ventilation holes 13-1 and inner ventilation holes 12-1 are arranged tangentially and alternately, the lower end surface of the air supply cavity 13-4 is closed or provided with end surface ventilation holes 13-2, and the secondary air intake is passed by the blower through the secondary The air inlet pipe is introduced from outside the furnace and connected to the cylindrical air supply cavity through the air inlet hole 13-3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com