A mobile energy storage device using copper foam phase change material

A phase change material and energy storage device technology, applied in the field of energy storage, can solve the problems of high pressure in the sealing cavity, low heat transfer efficiency, slow thermal response, etc., and achieve the effects of safe and reliable work, high heat transfer efficiency, and increased thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

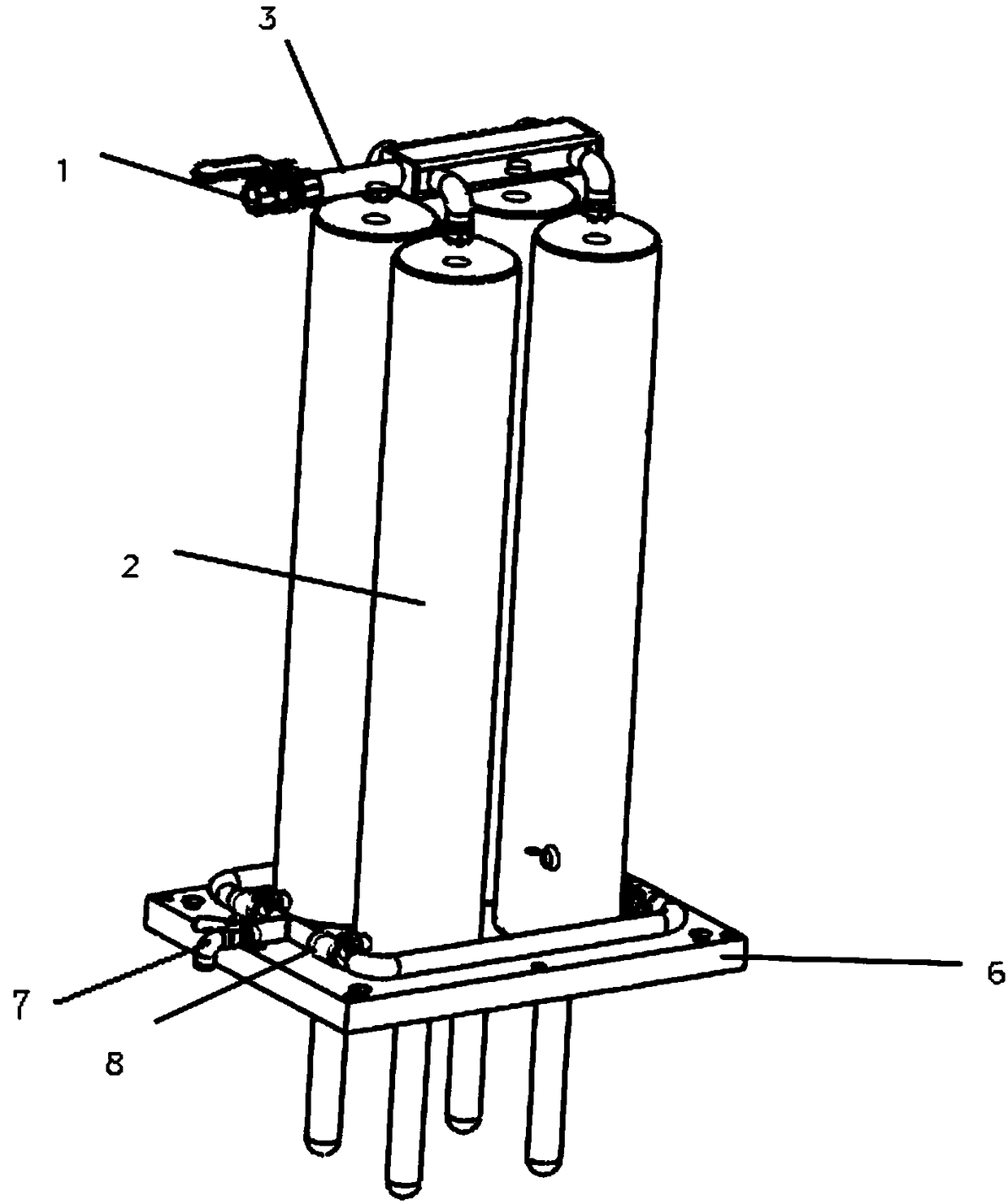

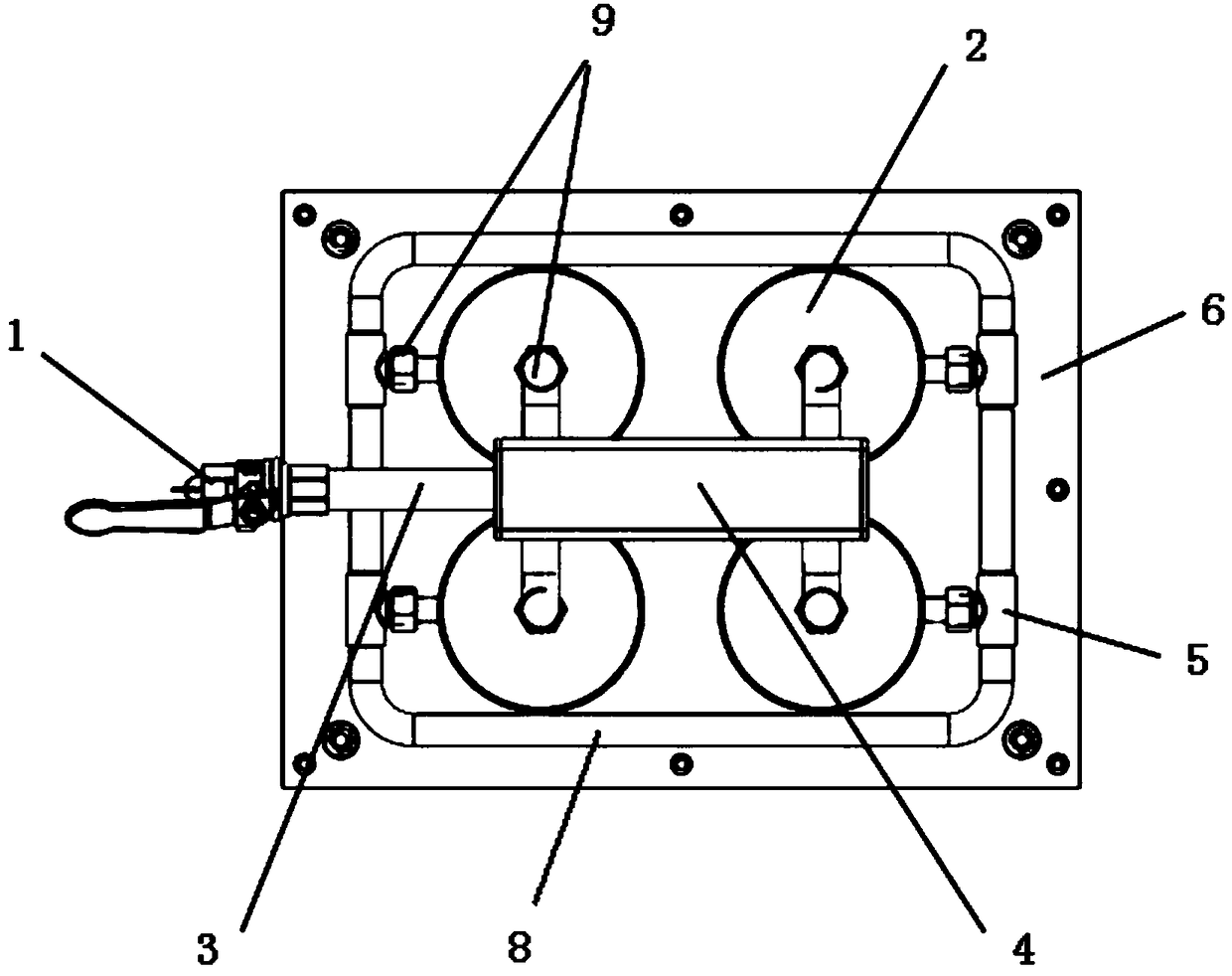

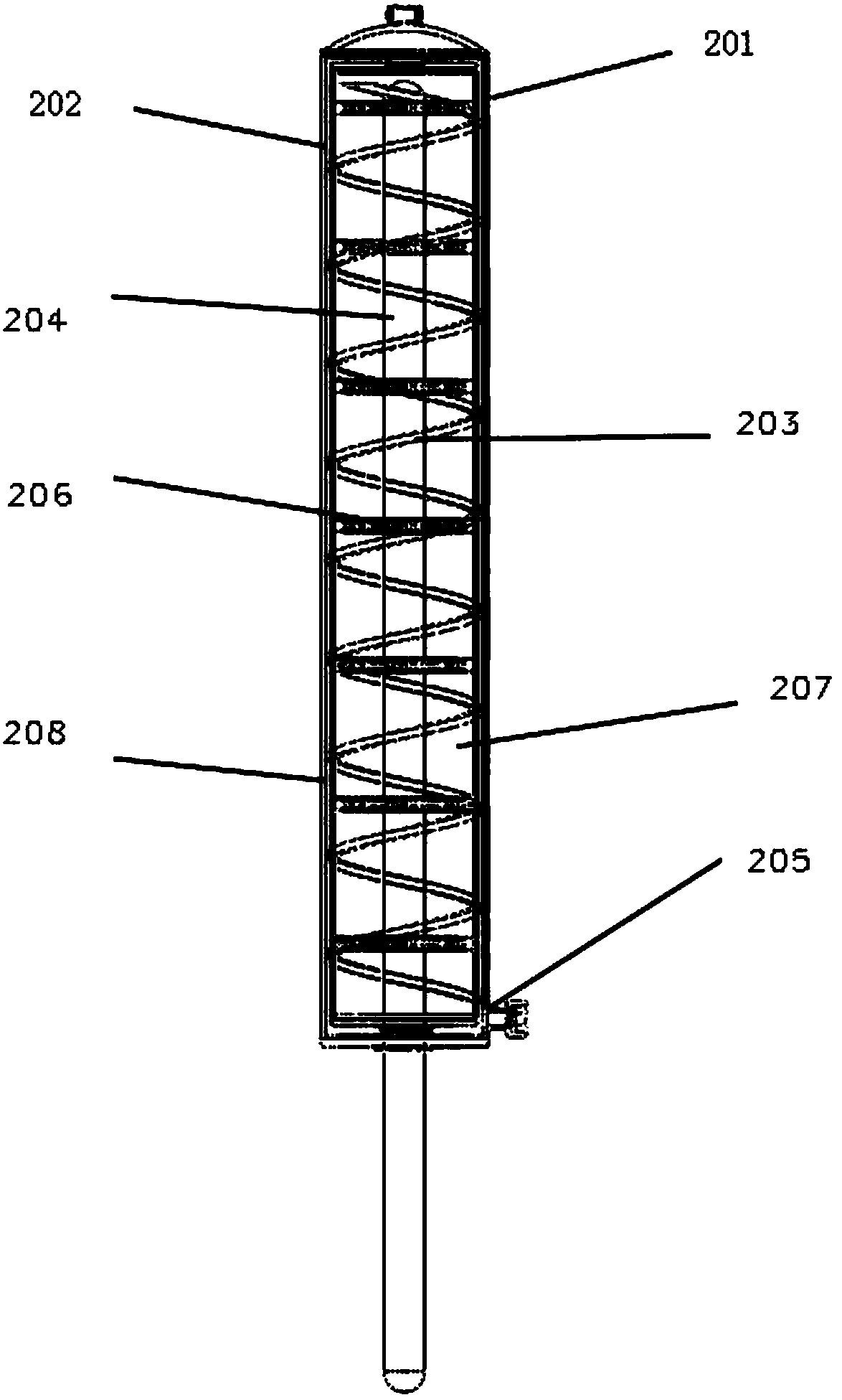

[0036] Such as figure 1 , figure 2 As shown, the present invention uses a mobile energy storage device of foamed copper phase change material, which includes a plurality of single phase change heat accumulators 2 connected in parallel; as image 3 , Figure 4 As shown, the single phase change heat accumulator 2 includes a closed cylindrical shell, and the cylindrical shell is divided into three layers, which are the outer stainless steel sleeve 201, the inner copper sleeve 208, and the The interlayer 202 between the outer stainless steel sleeve and the inner copper sleeve; the upper end of the cylindrical shell is provided with a water inlet, which communicates with the interlayer; the lower side of the cylindrical shell is provided with a water outlet, which is connected to the The interlayer is connected; there is an opening at the bottom of the shell that can be inserted into the superconducting heat pipe; the superconducting heat pipe is inserted into the inner layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com