Fuzzy control coal dressing method

A technology of fuzzy control and coal preparation, applied in the direction of adaptive control, general control system, non-electric variable control, etc., can solve problems such as wrong conclusions, mathematical models matching, and inability to obtain accurate mathematical models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] refer to Figure 1 to Figure 7 The embodiments of the present invention will be further described.

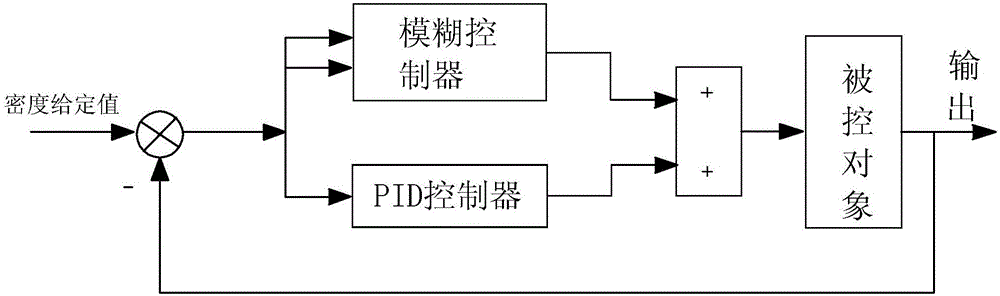

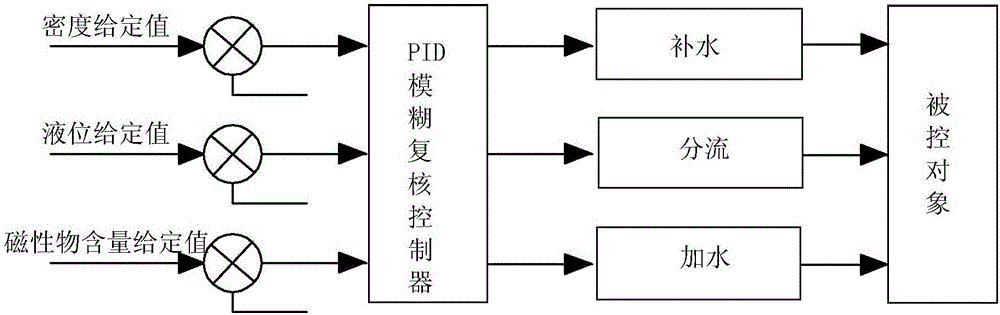

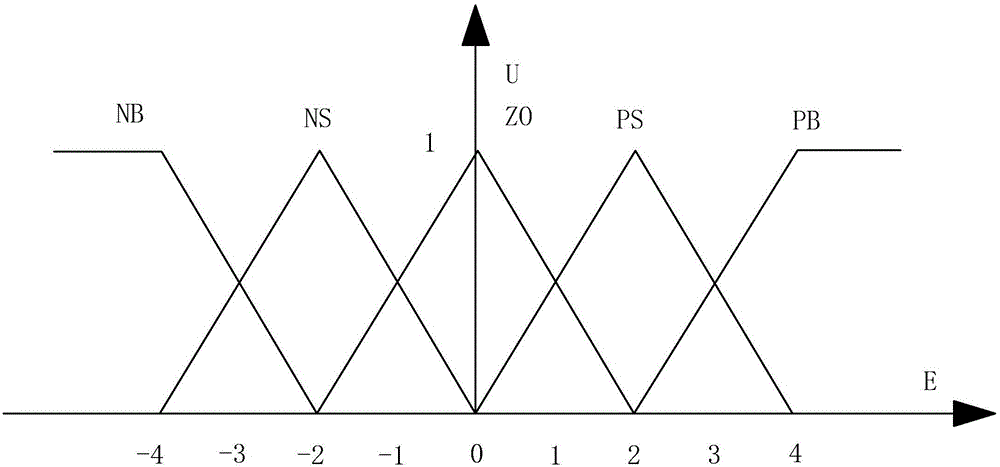

[0029] Taking the relationship between coal washing equipment and the process parameters that affect the quality and efficiency of coal washing as the research object, a set of dense medium coal washing centralized monitoring and process parameter automatic measurement and control system is designed by combining the relatively mature technology of PID controller and fuzzy control theory. On-line detection, monitoring and stable control of process parameters in the process of dense medium coal washing, to solve the current situation of difficult adjustment of system response speed and overshoot due to large lag and large inertia links in the current heavy medium suspension and liquid level control system , so as to optimize the coal washing process, improve labor productivity, reduce labor intensity of workers, and improve economic benefits.

[0030] The system adopts ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com