A plunge grinding process parameter optimization method based on a grinding removal rate model

A technology for process parameter optimization and plunge grinding, which is used in electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

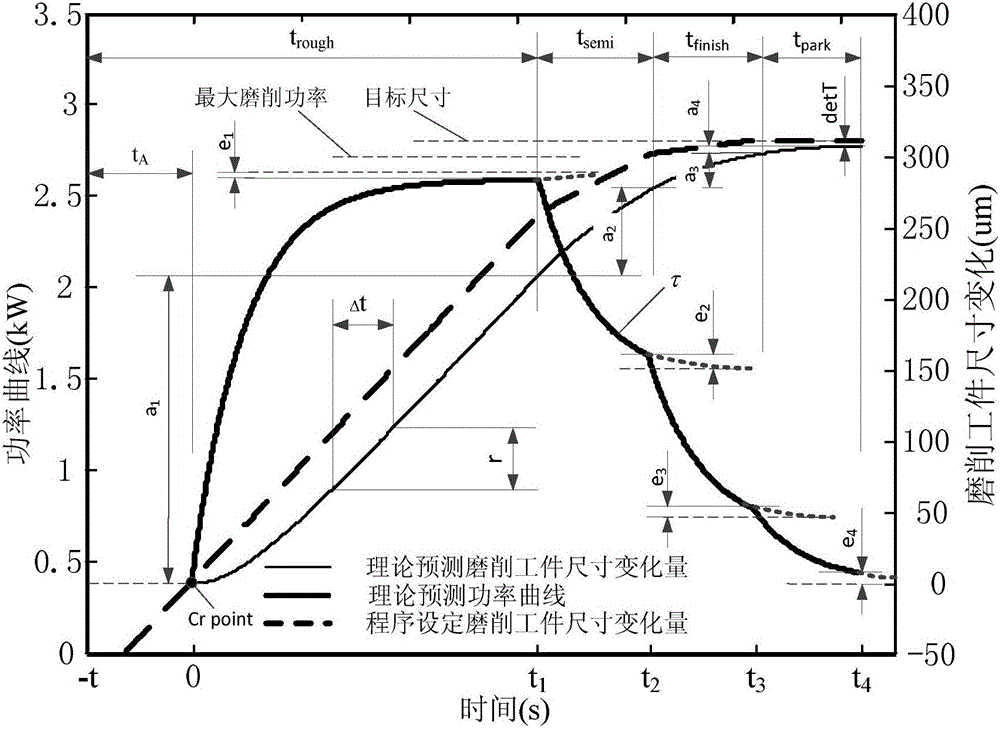

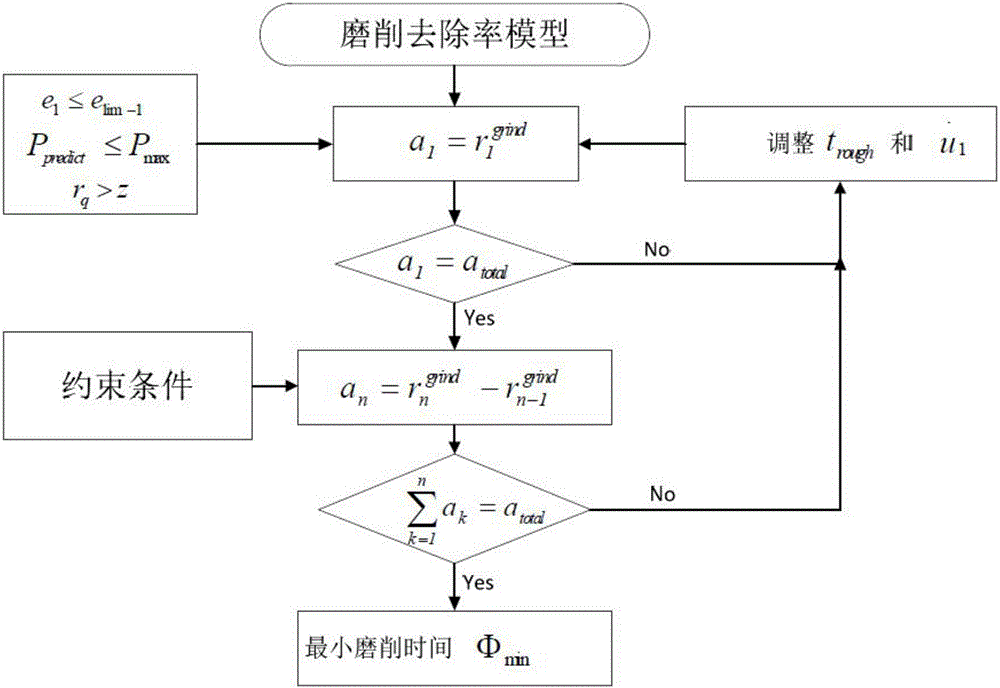

[0098] Such as image 3 As shown, an optimization method of plunge grinding process parameters based on the grinding removal rate model, the specific steps are:

[0099] 1. Establish the theoretical model of plunge grinding removal rate

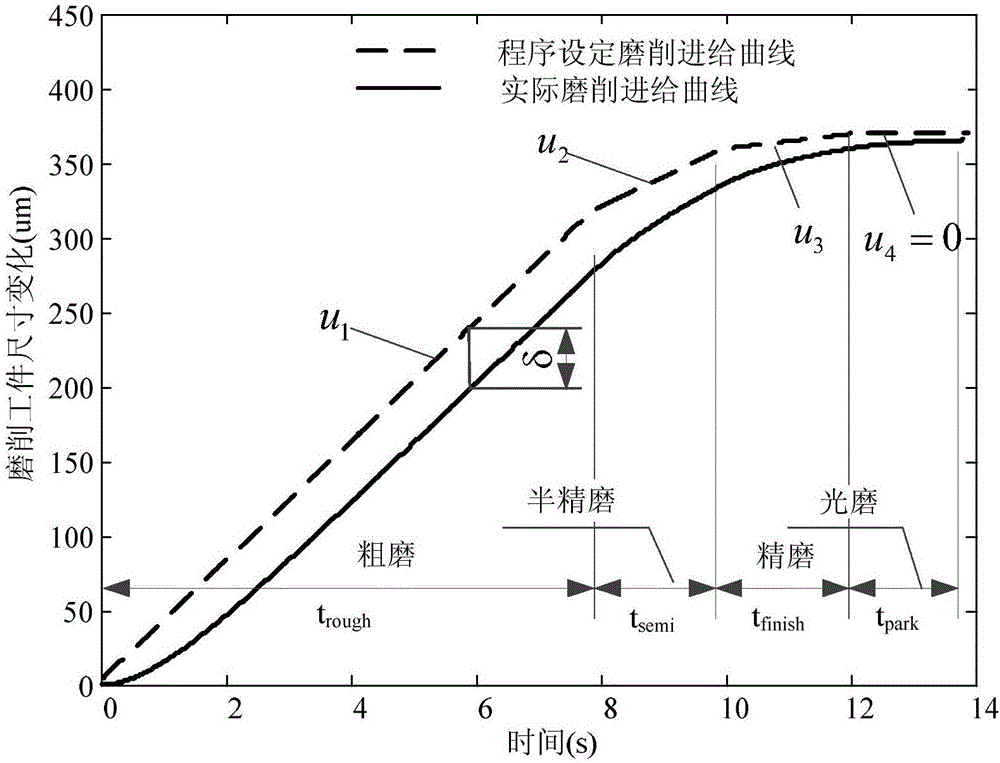

[0100] Due to the elastic deformation of the plunge grinding system, the actual feed rate in the grinding feed stage always lags behind the feed rate set by the NC command. During the plunge grinding feed process, due to the normal grinding force F n The resulting elastic deformation δ can be expressed as:

[0101]

[0102] In the formula, F n is the normal grinding force at the contact point between the grinding wheel and the workpiece, δ is the elastic deformation, k e is the equivalent stiffness of the system.

[0103] Normal grinding force F in plunge grinding n and actual feed speed Subject to a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com