Heat exchange structure with annular fins and heat dissipation device with heat exchange structure

A technology of heat exchange structure and heat dissipation device, which is applied to electrochemical generators, electrical components, circuits, etc., can solve the problems of excessive weight of heat dissipation fins, complicated processes, and large volume, and achieves reduction of material cost and manufacturing cost, Small size and weight, enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

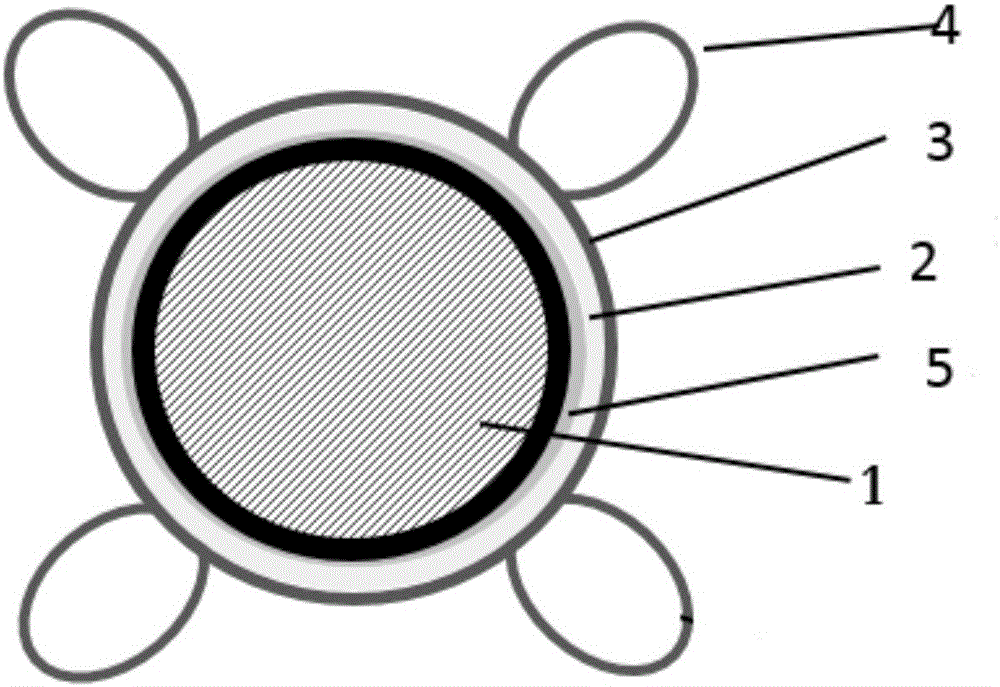

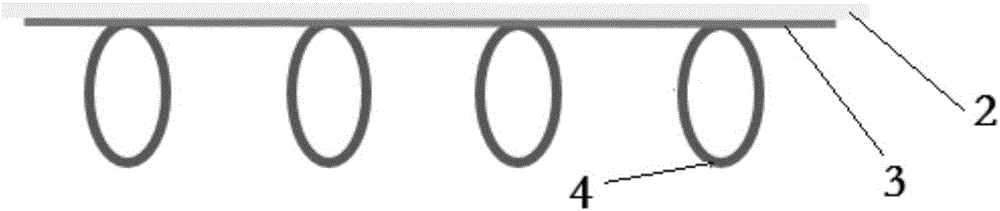

[0044] A heat exchange structure with annular fins, the structure of which is as follows figure 1 As shown, the heat exchange structure is used to enhance the heat dissipation capability of the heat-generating device to the external environment. The heat-exchange structure includes the heat-generating device 1, the interface heat-conducting adhesive layer 5, the wrapping tape 2 and the heat-conducting tape 3 from the inside to the outside, and the heat-conducting tape 3 is provided with 4 annular fins 4, wherein the material of the winding belt 2, the conductive belt 3 and the annular fin 4 is aluminum, the conductive belt 3 and the winding belt 2 are welded and connected, and the material of the interface thermally conductive adhesive layer 5 is EA9189. Among them, the structure of the heat conduction belt used in the heat exchange structure is as follows: figure 2 , image 3 As shown, the heat conduction tape 3 can be a continuous heat conduction tape or a disconnected hea...

Embodiment 2

[0046] A heat exchange structure with annular fins, the structure of which is as follows Figure 4 As shown, the heat exchange structure is to directly bend the conductive belt 3 to form four annular fins 4, which are fixed on the heat generating device 1, and the shape of the annular fins 4 is as follows: Figure 5 , Figure 6 As shown, the annular fin 4 can be elliptical or linear, and the shape of the annular fin 4 can be arbitrarily selected according to the requirement of heat exchange capacity, as long as it extends outward on the basis of the conduction belt 3 Can.

Embodiment 3

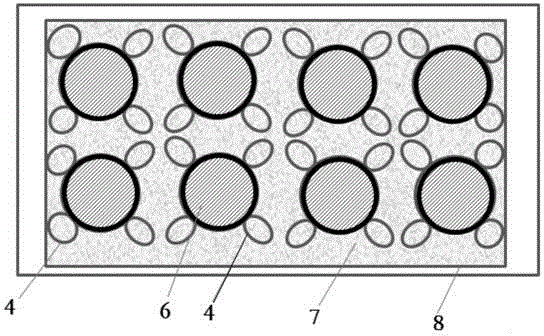

[0048] A heat exchange structure with annular fins, its structure is similar to Embodiment 1, the difference is that there are 8 annular fins in this embodiment, the specific structure is as follows Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com