Zero-tolerance depth-controllable drilling method for circuit board

A drilling method and circuit board technology, which are applied in the directions of printed circuits, printed circuit manufacturing, and the formation of electrical connection of printed components, can solve the problems of small design aperture accuracy, limited angle of ordinary drill tip, and insufficient flatness of drilling rigs. Guarantee quality and reliability, meet the needs of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

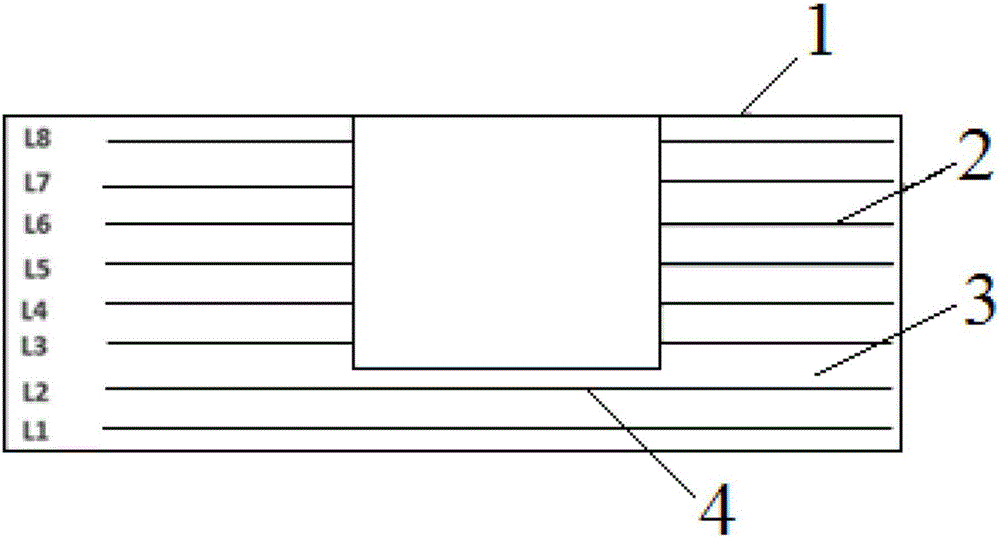

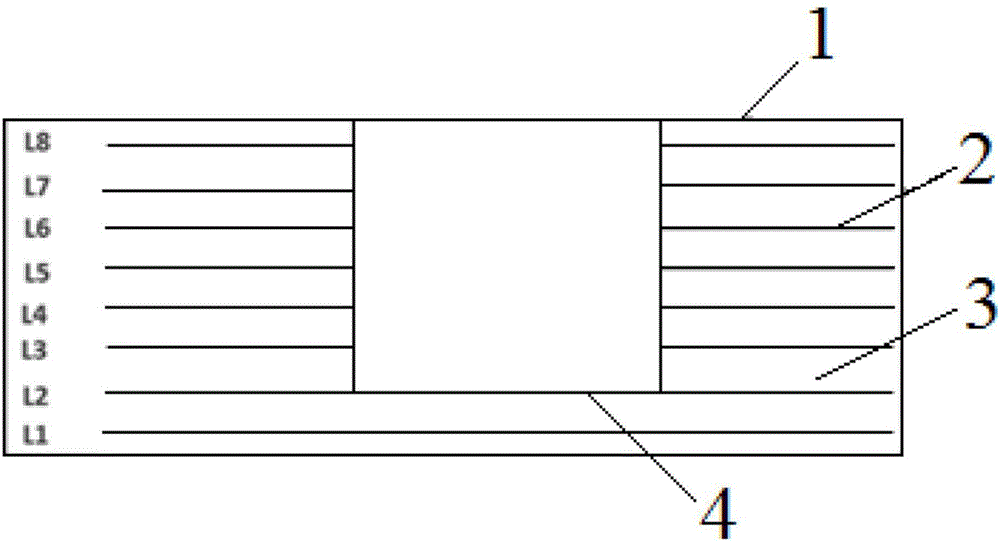

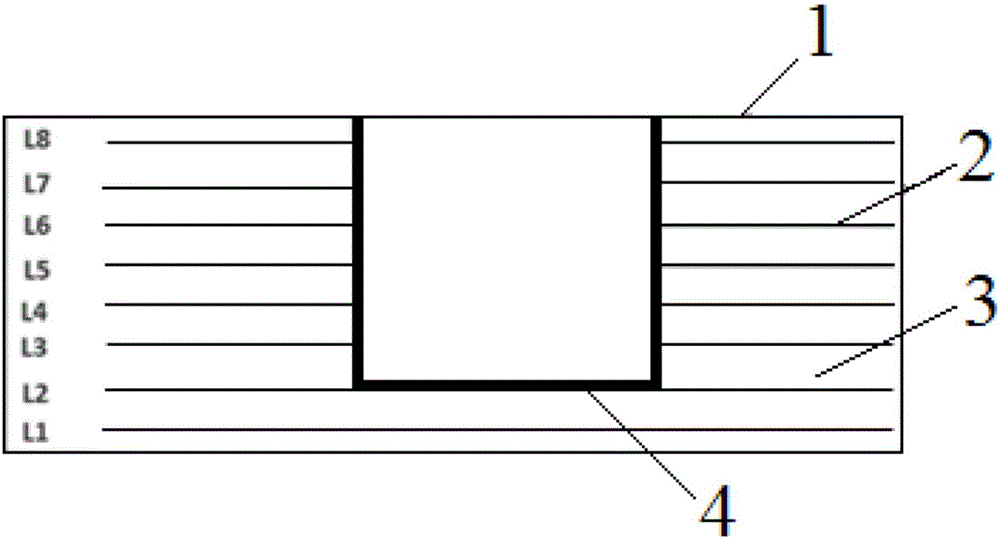

Image

Examples

Embodiment

[0023] This embodiment provides a zero-tolerance controlled deep drilling method for a circuit board, which includes the following steps:

[0024] a. Cutting, cutting copper plates and prepregs and other incoming materials into plates of moderate size according to the design requirements of different plate sizes, removing the oily substance oxide film on the copper plate surface by conventional methods, and performing chemical microetching to make the copper surface occur Redox reaction roughens the copper surface.

[0025] b. Inner layer circuit pattern production, film production, after the required circuit pattern is made on the film film, the dry film is laminated on the surface of the inner core board, and the photosensitive film in the dry film is reacted by exposure, selective partial bridge After hardening, the dry film of the unexposed part is removed, and the photosensitive part is retained, thereby transferring the pattern on the film to the surface of the inner core pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com