Expansion tank-integrated heat exchanger and boiler including same

An expansion tank and heat exchanger technology, applied in water heaters, indirect heat exchangers, heat exchanger shells, etc., can solve problems such as loss of expansion tank functions, prevent deformation or malfunction, reduce manufacturing unit price, and facilitate The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, an expansion tank-integrated heat exchanger and a boiler including the heat exchanger according to preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

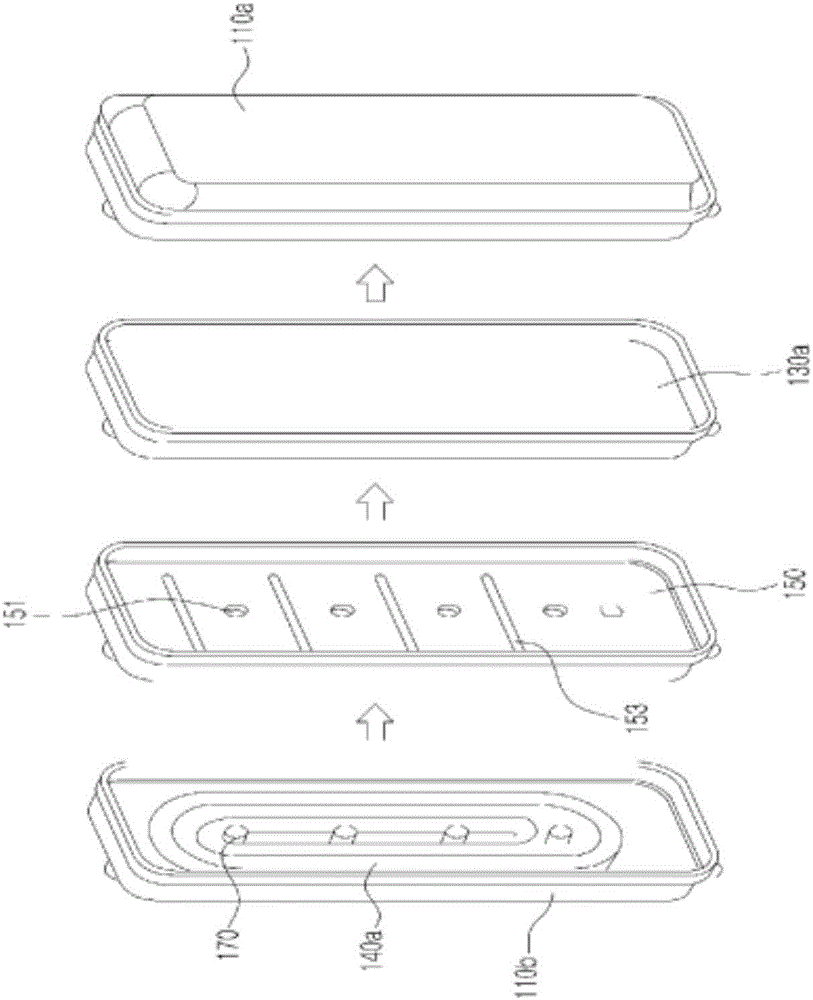

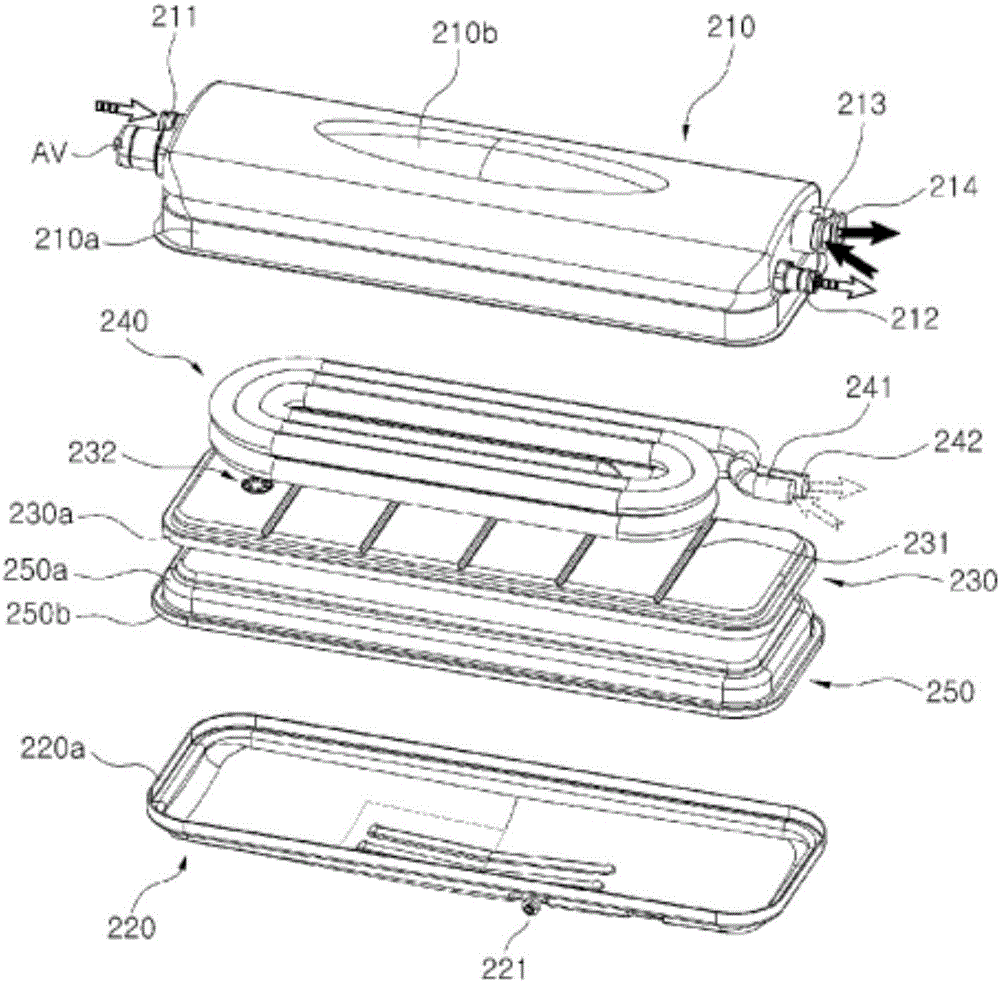

[0036] First, if image 3 As shown, the expansion tank integrated heat exchanger (200) of the present invention includes: a water chamber shell (210), a gas chamber shell (210), a partition (230), a warm water heat exchange tube (240) and a diaphragm (250) . These structures are Figure 4 Assembled as shown.

[0037] Therefore, the water chamber casing (210) and the gas chamber casing (210) are combined to form a "heat exchanger casing", and a partition (230) is arranged in the heat exchanger casing to divide the water chamber and the gas chamber.

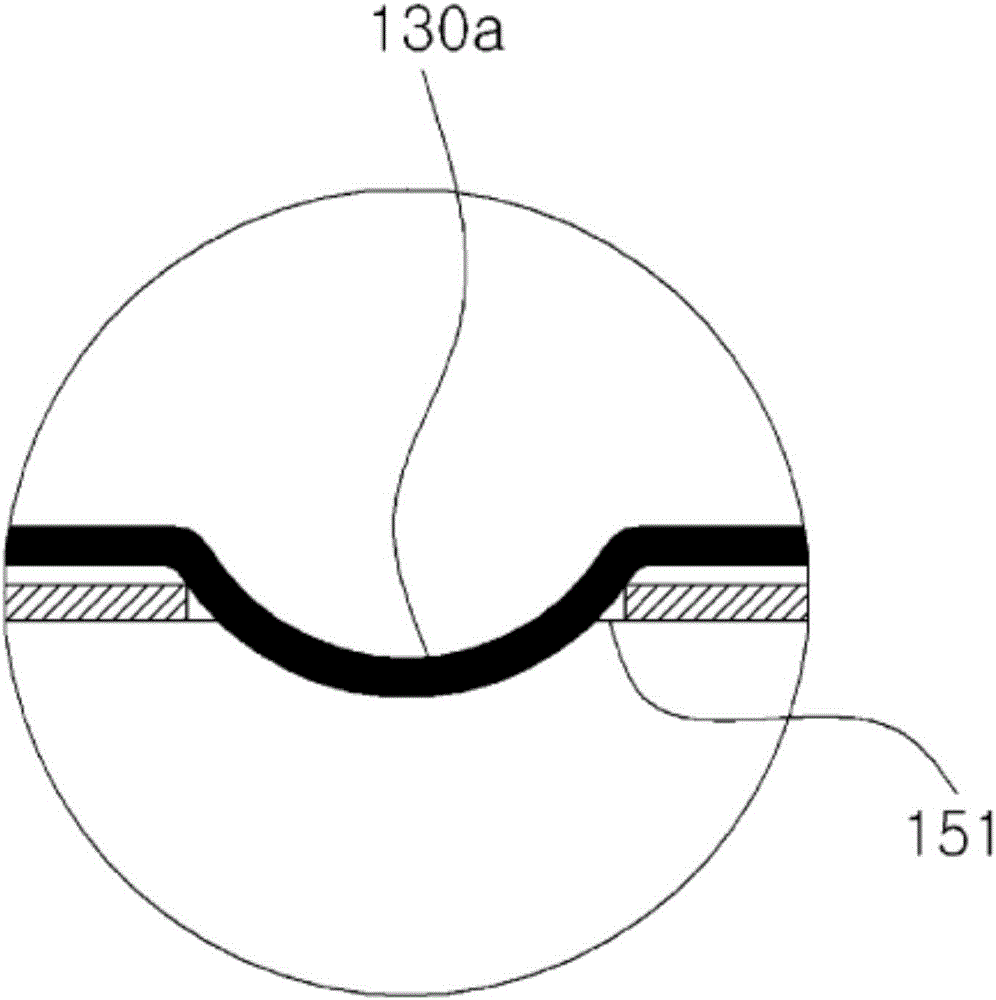

[0038] In addition, a warm water heat exchange tube (240) equivalent to a warm water heat exchanger is installed in the water chamber, and a diaphragm (250) equivalent to a pressure expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com