Film capacitor

A film capacitor, capacitor technology, applied in the direction of film/thick film capacitors, capacitors, fixed capacitor electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the configuration and manufacturing method of the film capacitor in the first embodiment will be described with reference to the drawings.

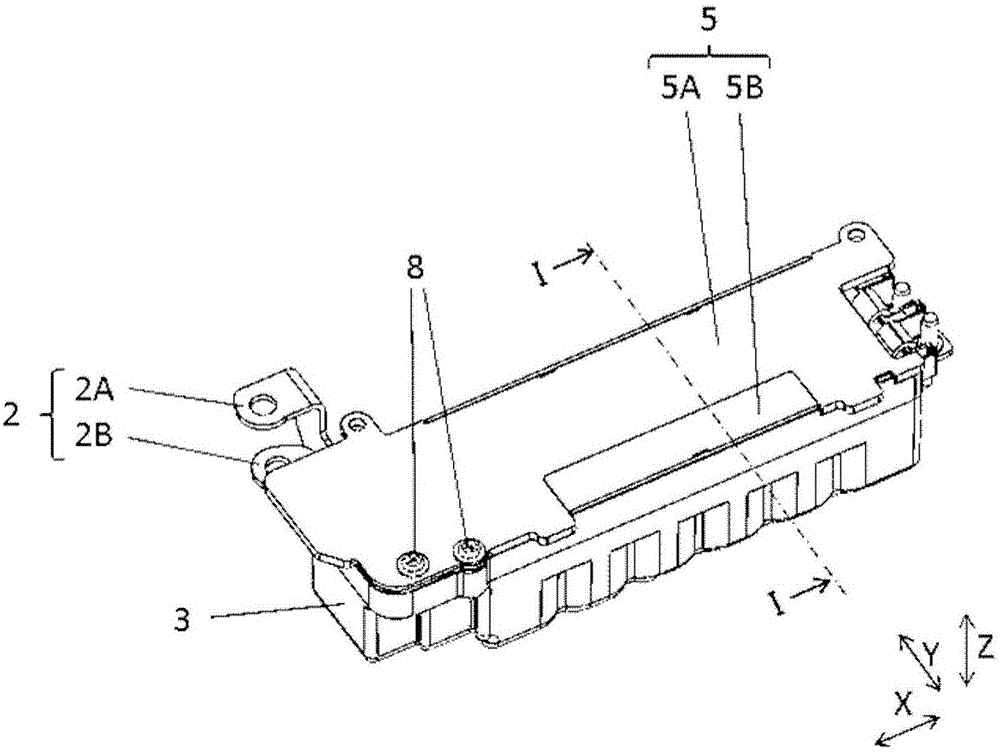

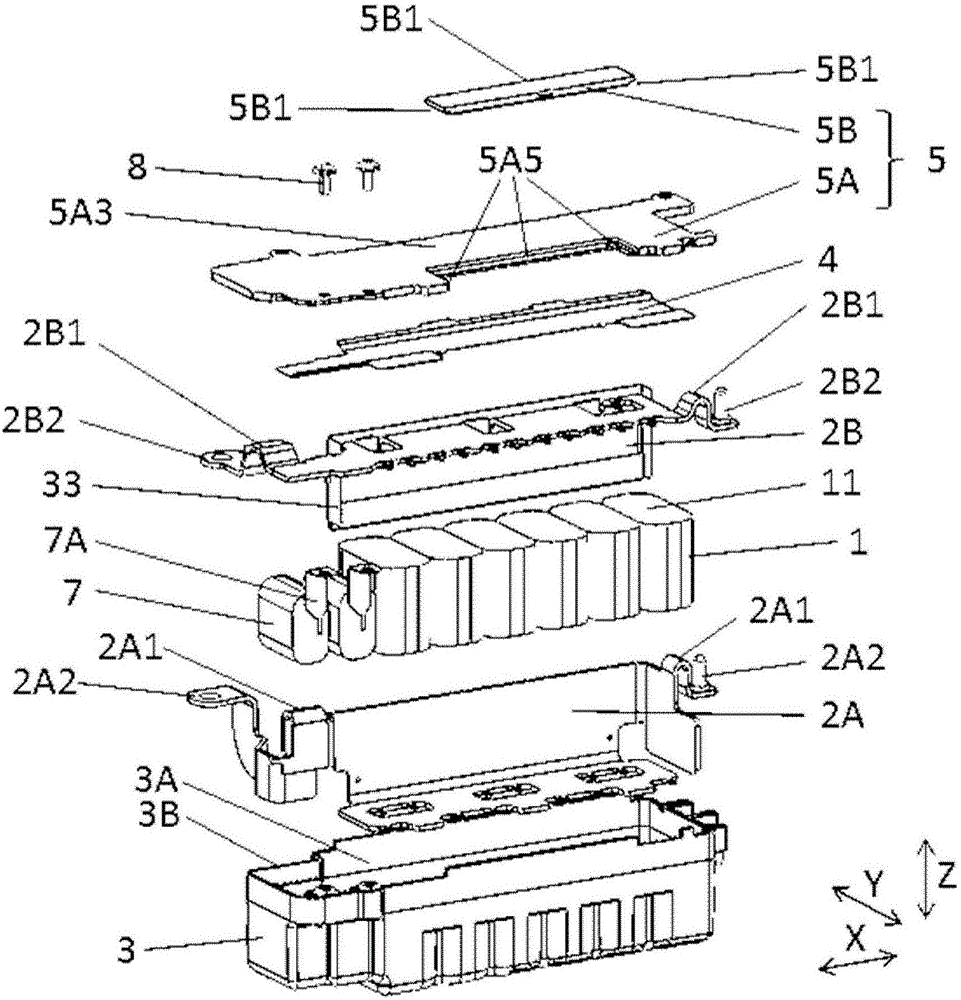

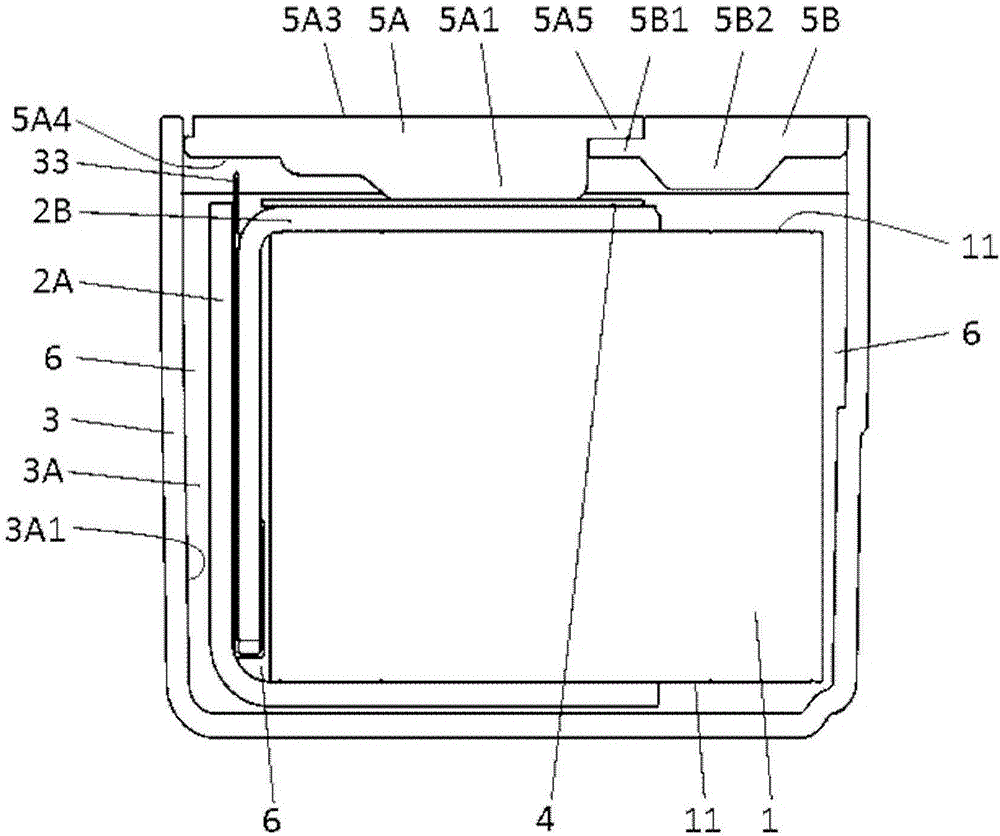

[0019] figure 1 is a perspective view of the film capacitor of the first embodiment, figure 2 It is an exploded perspective view of the main part of a film capacitor. also, image 3 yes figure 1 Sectional view at cutting line I-I of .

[0020] In this embodiment, the film capacitor includes six capacitor elements 1 for current smoothing. Metallization electrodes 11 are formed at both ends of each capacitor element 1 . Here, the configuration of the capacitor element 1 will be described in detail. The capacitor element 1 has two opposite end surfaces and a side surface connecting the two end surfaces, and has a flat shape (a shape having two flat surfaces and two curved surfaces) when viewed from the end surfaces. In addition, the capacitor element 1 includes a pair of metalized thin films. The metallized fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com