Instant needle mushroom

A technology of Flammulina velutipes and Flammulina velutipes, applied in the direction of food science, etc., can solve the problem that the nutritional value of Flammulina velutipes cannot be further improved, and achieve the effects of short processing time, less loss of nutrients, and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

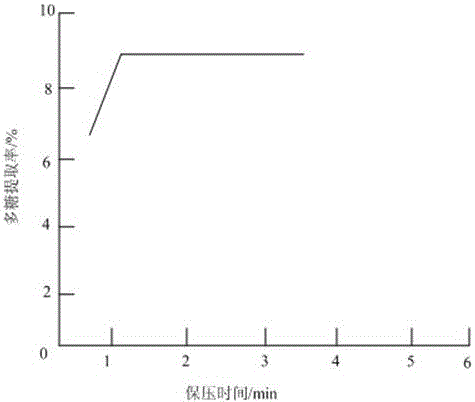

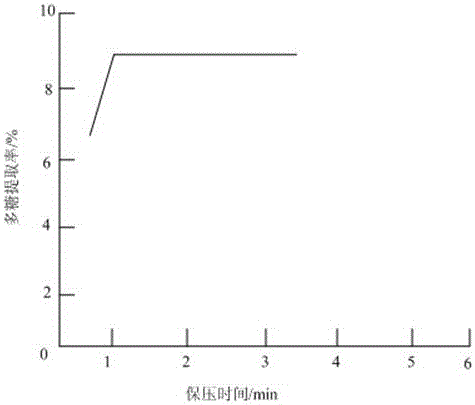

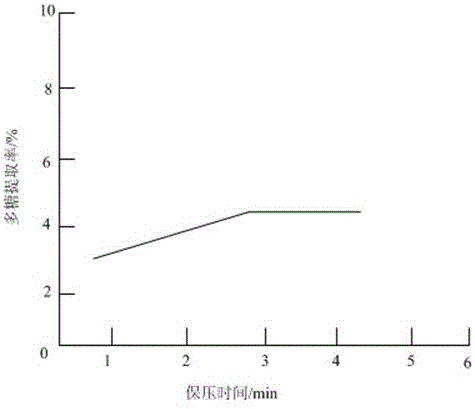

Image

Examples

Embodiment 1

[0013] Embodiment 1, select fresh, undamaged Flammulina velutipes as production raw material, put Flammulina velutipes into clear water and clean the surface with culture slag, wash repeatedly 3 times, pay attention to keep the mushroom body of Flammulina velutipes intact in the cleaning process, drain the washed Flammulina velutipes Dry the water, dry at a drying temperature of 38°C until there is no moisture on the surface, inoculate Bacillus subtilis with 2% of the weight of Flammulina velutipes, cultivate at 35°C for 14 hours, mix Flammulina velutipes with seasonings evenly, and season Flammulina velutipes Steam under high pressure for 30 seconds, the high pressure temperature is controlled at 90° C., and the pressure is 0.09 MPa. The Flammulina velutipes after high pressure steaming is sterilized and vacuum-packed.

Embodiment 2

[0014] Embodiment 2, select fresh, undamaged Flammulina velutipes as production raw material, put Flammulina velutipes into clear water and clean the surface to adhere to culture slag, wash repeatedly 3 times, pay attention to keep the mushroom body of Flammulina velutipes intact in the cleaning process, drain the washed Flammulina velutipes Dry the water, dry at a drying temperature of 39°C until the surface is free of moisture, inoculate Bacillus subtilis with 3% of the weight of Flammulina velutipes, cultivate at 36°C for 16 hours, mix Flammulina velutipes with seasonings evenly, and season Flammulina velutipes Steam under high pressure for 35 seconds, the high pressure temperature is controlled at 90.5° C., and the pressure is 0.092 MPa. The Flammulina velutipes after high pressure steaming is sterilized and vacuum-packed.

Embodiment 3

[0015] Embodiment 3, select fresh, undamaged Flammulina velutipes as production raw material, put Flammulina velutipes into clear water and clean the surface to attach culture slag, wash repeatedly 3 times, pay attention to keeping the mushroom body of Flammulina velutipes intact during the cleaning process, drain the washed Flammulina velutipes Dry the water, dry at a drying temperature of 40°C until there is no moisture on the surface, inoculate Bacillus subtilis with 4% of the weight of Flammulina velutipes, cultivate at 36°C for 18 hours, mix Flammulina velutipes with seasoning evenly, and season Flammulina velutipes Steam under high pressure for 45 seconds, the high pressure temperature is controlled at 91.5° C., and the pressure is 0.096 MPa. The Flammulina velutipes after high pressure steaming is sterilized and vacuum-packed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com