Metal pillared montmorillonite supported gamma-MnO2 low-temperature denitration catalyst and preparation method thereof

A low-temperature denitrification and montmorillonite technology, applied in the field of denitrification catalysis, can solve the problems of expensive catalyst carrier, high reaction temperature, and poor catalyst performance, and achieve excellent anti-SO2 performance, good low-temperature activity, and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

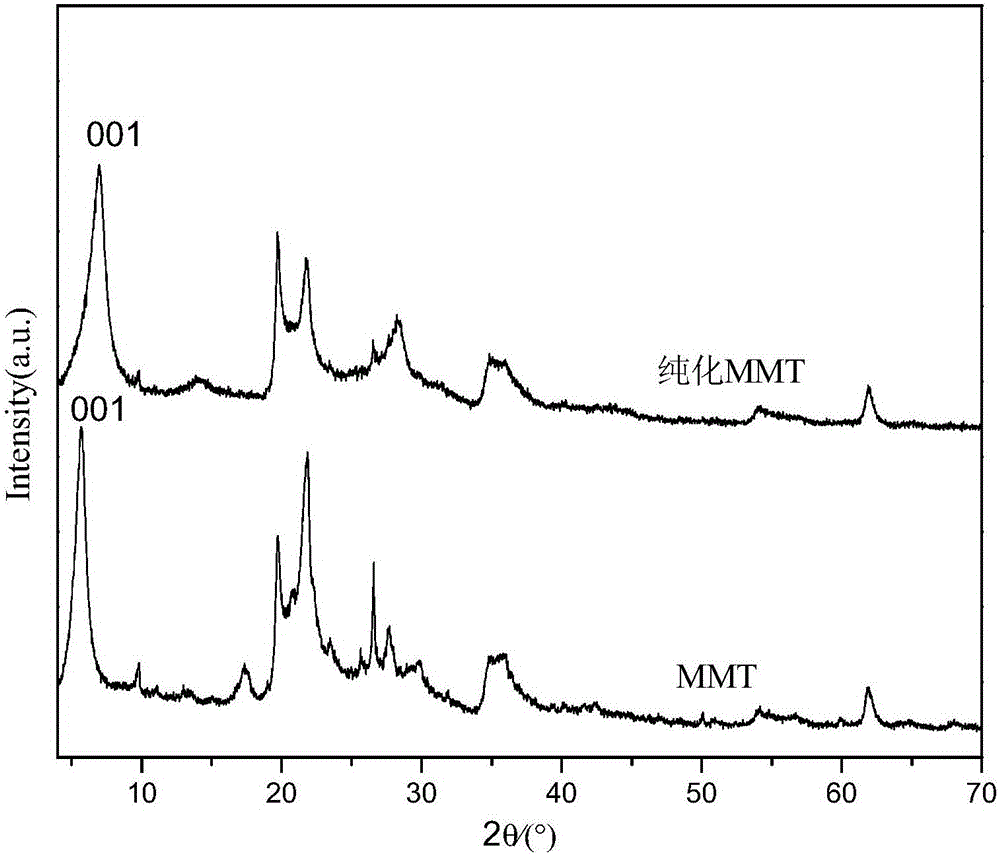

Embodiment 1

[0021] 1. Weigh about 100g of calcium-based montmorillonite raw soil and disperse it in 1.5mol / L (NaPO 3 ) 6 In the solution, adjust the pH of the solution to 7 with ammonia water, and add 5wt% NaCl at the same time to replace the interlayer Ca of montmorillonite. 2+ , and use 4000 ~ 5000r / min emulsification machine pulp, stand still for about 24h, use the method of siphon to remove the upper layer slurry, and filter, wash and dry to get Na-MMT, weigh 45g Na-MMT and dissolve in deionized Make up about 9g / 100mL slurry in water.

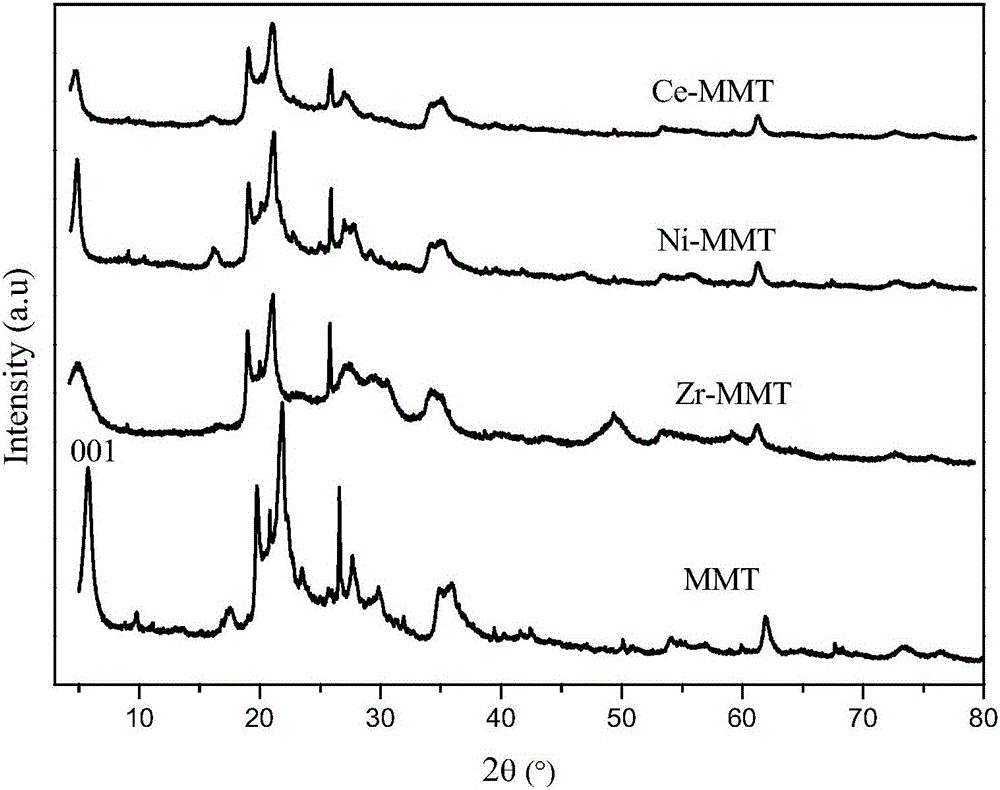

[0022] 2. Weigh 2.67g Ni(NO 3 ) 2 .6H 2 O was dissolved in deionized water, and the slurry made in 50mL step 1 was measured in a 250mL three-necked flask, and the dissolved Ni(NO 3 ) 2 .6H 2 O was slowly added dropwise into the three-necked flask, and the molar ratio of Ni metal to montmorillonite was controlled to be 0.03:1. Stirring was continued, and the temperature was raised to 80°C for 3.5 hours, then moved to a stainless steel autoclave a...

Embodiment 2

[0028] 1. Weigh about 100g of calcium-based montmorillonite raw soil and disperse it in 1.5mol / L (NaPO 3 ) 6 In the solution, adjust the pH of the solution to 7 with ammonia water, and add 5wt% NaCl at the same time to replace the interlayer Ca of montmorillonite. 2+ , and use 4000 ~ 5000r / min emulsification machine pulp, stand still for about 20h, use the method of siphon to remove the upper layer slurry, and filter, wash and dry to get Na-MMT, weigh 45g Na-MMT and dissolve in deionized Make up about 9g / 100mL slurry in water.

[0029] 2. Weigh 4.62g of ZrO(NO 3 ) 2 .XH 2 O was dissolved in deionized water, and the slurry made in 50mL step 1 was measured in a 250mL three-necked flask, and the dissolved ZrO(NO 3 ) 2 .XH 2 O was slowly added dropwise into the three-necked flask, and the molar ratio of Zr metal to montmorillonite was controlled to be 0.03:1, and the stirring was continued, and the temperature was raised to 80°C for 3.5 hours, and then moved to a stainless ...

Embodiment 3

[0032] 1. Weigh about 100g of calcium-based montmorillonite raw soil and disperse it in 1.5mol / L (NaPO 3 ) 6 In the solution, adjust the pH of the solution to 7 with ammonia water, and add 5wt% NaCl at the same time to replace the interlayer Ca of montmorillonite. 2+ , and use 4000 ~ 5000r / min emulsification machine pulp, stand still for about 20h, use the method of siphon to remove the upper layer slurry, and filter, wash and dry to get Na-MMT, weigh 45g Na-MMT and dissolve in deionized Make up about 9g / 100mL slurry in water.

[0033] 2. Weigh 8g of Ce(NO 3 ).6H 2 O was dissolved in deionized water, and the slurry made in 50mL step 1 was measured in a 250mL three-necked flask, and the dissolved Ce(NO 3 ).6H 2 Slowly add O into the three-necked flask, control the molar ratio of Ce metal and montmorillonite to 0.01:1, keep stirring, raise the temperature to 80°C for 3.5h, then move to a stainless steel autoclave at 150°C for 10h, after the reaction Further suction filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com