A method for intelligent configuration of cold rolling emulsion

An intelligent configuration and emulsion technology, which is applied in workpiece cooling devices, metal rolling, metal rolling, etc., can solve the problems of manual control of large fluctuations in concentration, improve stability and product quality, improve control accuracy, and roll stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

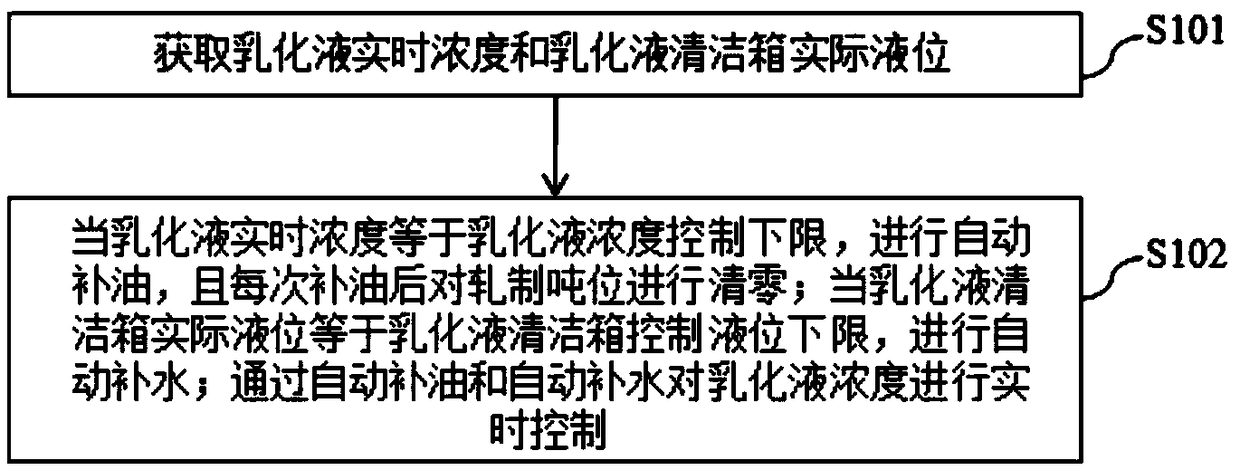

Method used

Image

Examples

Embodiment 1

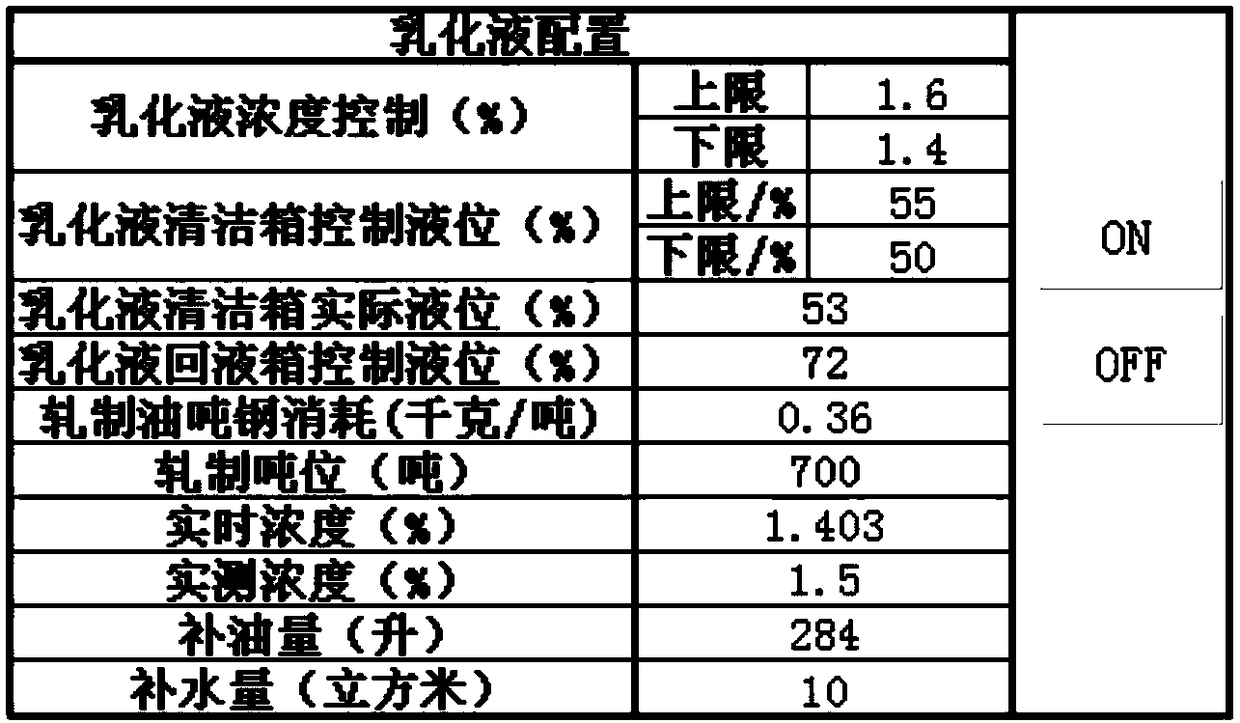

[0051] Emulsion concentration control upper limit = 1.6%, manually set

[0052] Lower control limit of emulsion concentration = 1.4%, manually set

[0053] Emulsion cleaning tank maximum volume = 200m 3 , the device constant

[0054] The maximum volume of the emulsion return tank = 50m 3 , the device constant

[0055] Emulsion cleaning tank control liquid level upper limit = 55%, manually set

[0056] Emulsion cleaning tank control liquid level lower limit = 50%, manually set

[0057] Emulsion liquid return tank control liquid level = 72%, liquid level gauge collection and monitoring

[0058] Rolling oil consumption per ton of steel = 0.36 kg / ton, manually set

[0059] Rolling oil volume per barrel = 200L = 0.2m 3 ,constant

[0060] Rolling oil weight per barrel = 180kg, constant

[0061] The actual liquid level of the emulsion cleaning tank is monitored in real time by a liquid level gauge.

[0062] The rolling tonnage is collected from the secondary system and is aut...

Embodiment 2

[0070] The cold-rolled emulsion intelligent configuration method provided by the embodiment of the present invention is edited into computer software, and the operation interface of the computer software is as follows: figure 2 As shown, the upper control limit of the emulsion concentration is 1.6%, the lower control limit of the emulsion concentration is 1.4%, the upper limit of the control liquid level of the emulsion cleaning tank is 55%, the lower limit of the control liquid level of the emulsion cleaning tank is 50%, and the rolling oil consumption per ton of steel is 0.36 kg / Ton is a manual setting value, manually input into the setting box. The actual liquid level of the emulsion cleaning tank is 53%, the control liquid level of the emulsion return tank is 72%, and the rolling tonnage of 700 tons is automatically collected by the liquid level gauge and automatically calculated by the system. The real-time concentration is 1.403%, the oil replenishment volume is 284L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com