Valve stem laser marking apparatus

A laser marking and valve technology, which is used in typewriters, printing and other directions, can solve the problems of easy falling off and wear of markings, inability to mark the date of mixing, and achieve the effects of marking not easy to fall off, automatic continuous marking and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

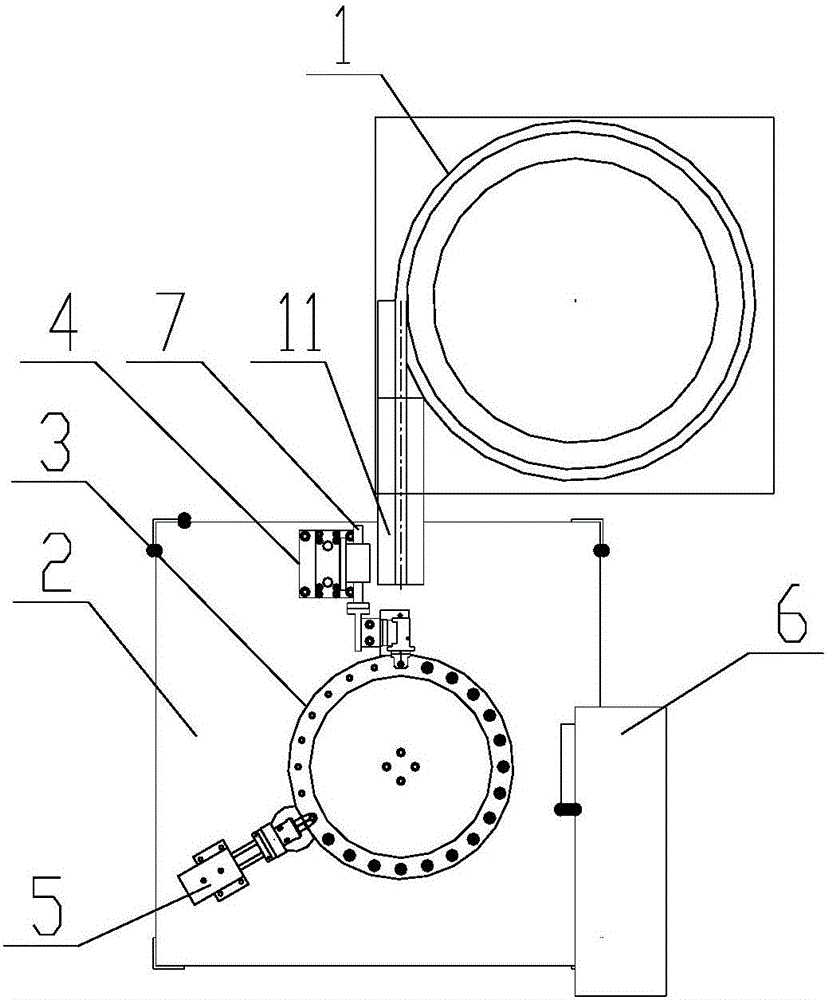

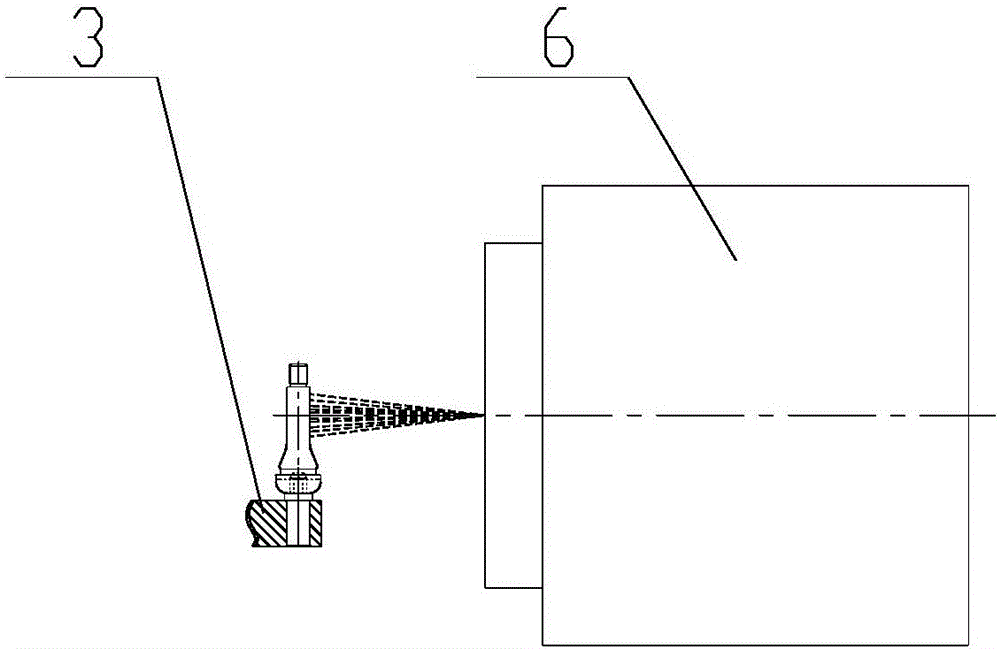

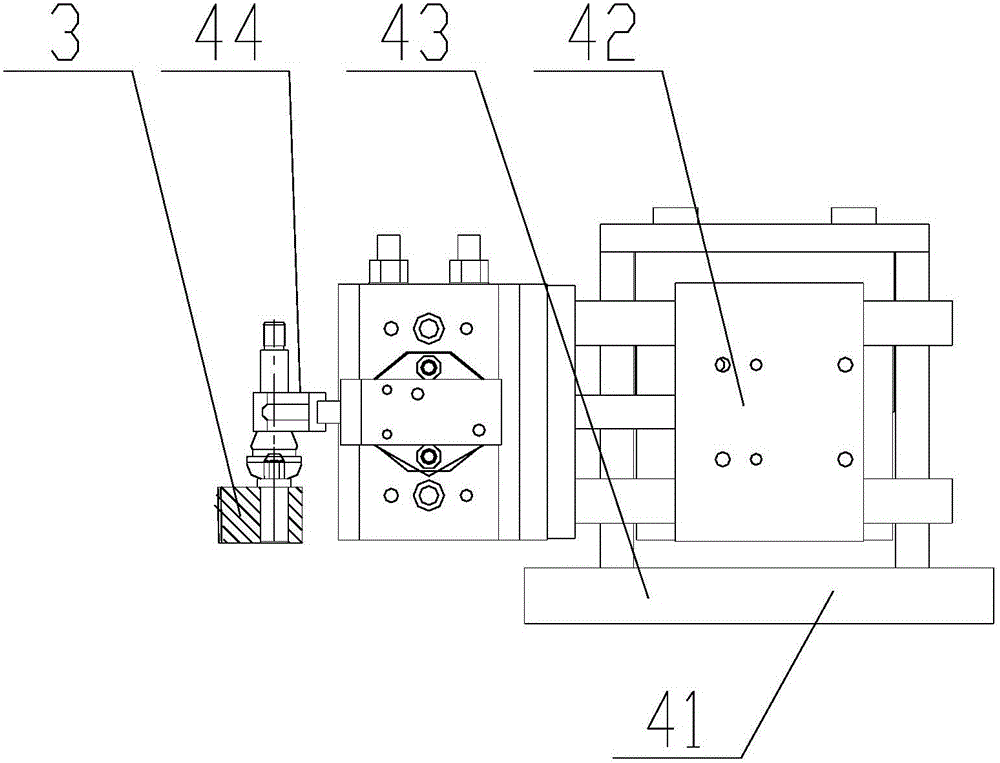

[0022] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of a valve laser marking device proposed by the present invention, figure 2 It is a structural schematic diagram of a laser marking mechanism of a valve laser marking device proposed by the present invention, image 3 It is a structural schematic diagram of a feeding manipulator of a valve laser marking device proposed by the present invention.

[0023] refer to figure 1 with 2 , a valve laser marking device proposed by the present invention, comprising: a vibrating feeding mechanism 1, a workbench 2, a loading tray 3, a feeding manipulator 4, a feeding manipulator 5, a laser marking mechanism 6, and a driving mechanism;

[0024] The workbench 2 is provided with a vertically arranged first rotating shaft, and the loading tray 3 is rotatably mounted on the workbench 2 through the first rotating shaft. The driving mechanism is connected with the loading tray 3 to drive the loading tray 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com