Tire internal detonation device for testing tire burst property based on three-dimensional movement

A detonating device, three-dimensional motion technology, applied in the direction of automobile tire testing, tire parts, transportation and packaging, etc., can solve the problem of non-referencing, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

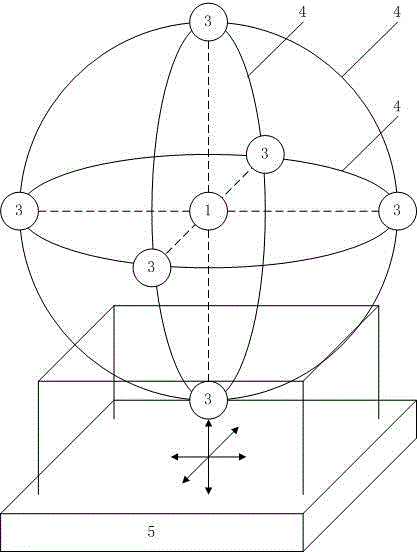

[0023] The detonation device in the tire of the tire blowout performance test based on three-dimensional motion of the present embodiment comprises a spherical casing 1, a detonating device 2 arranged in the spherical casing 1, and three sets of permanent magnets 3 symmetrically arranged on the outside of the spherical casing 1 for fixing The frame 4 of the permanent magnet 3 is used to control the three-dimensional translation platform 5 of the movement of the frame 4; the spherical shell 1 is arranged inside the tire, and the permanent magnet 3, the frame 4 and the three-dimensional translation platform 5 are arranged outside the tire;

[0024] Among them, the position and structural relationship among the spherical shell 1, three sets of permanent magnets 3, the frame 4 and the three-dimensional translation platform 5 are as follows: figure 1 shown;

[0025] The spherical shell 1 is a hollow spherical magnet with ventilation holes, the positive hemisphere is the N pole, and...

specific Embodiment 2

[0032] The three-dimensional motion-based tire blowout performance testing device in the present embodiment further defines a position tracking system on the basis of the specific embodiment 1. The reference system of the position tracking system is set outside the tire, and the moving part is set In the spherical housing 1, the moving part also includes a protective cover.

[0033] In this embodiment, the position tracking system selects the Fastrak system that can be purchased as a finished product. The transmitter of the Fastrak system is arranged outside the tire as a reference frame, and the receiver of the Fastrak system is arranged in the spherical housing 1 as a moving part. The receiver Also includes protective cover.

[0034] The function of the protective cover is to avoid blowing up the moving part when the gunpowder is detonated, making the position tracking system a reusable system and reducing the cost of experiments.

[0035] This structural limitation enables...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com