SMA wire driving catapult releasing device

A technology of releasing device and compressing spring, applied in the aerospace field, can solve the problems of large impact of the unlocking and releasing mechanism of the spacecraft, cannot be reused, complex structure, etc., and achieves the effects of quick unlocking and releasing response, easy operation and large payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

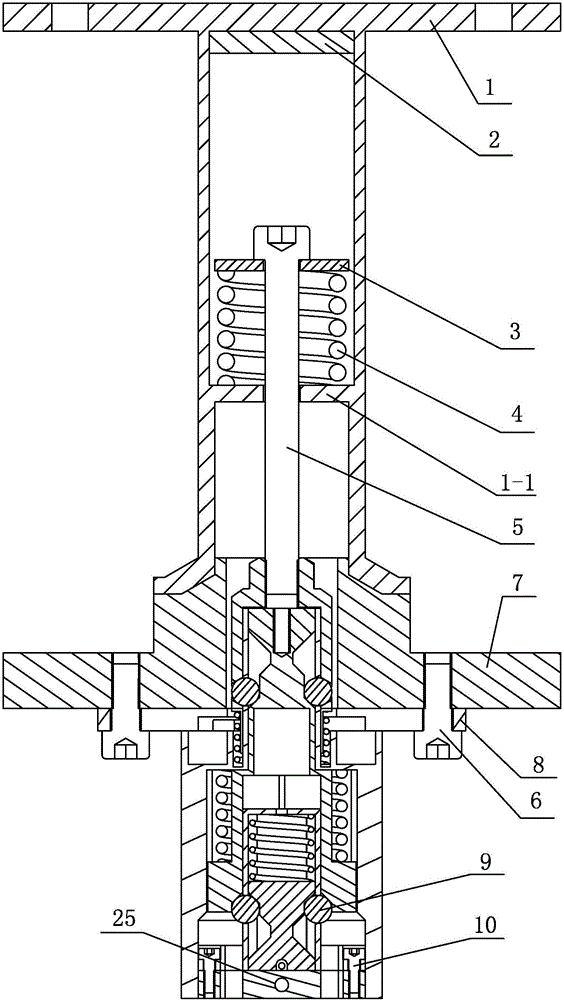

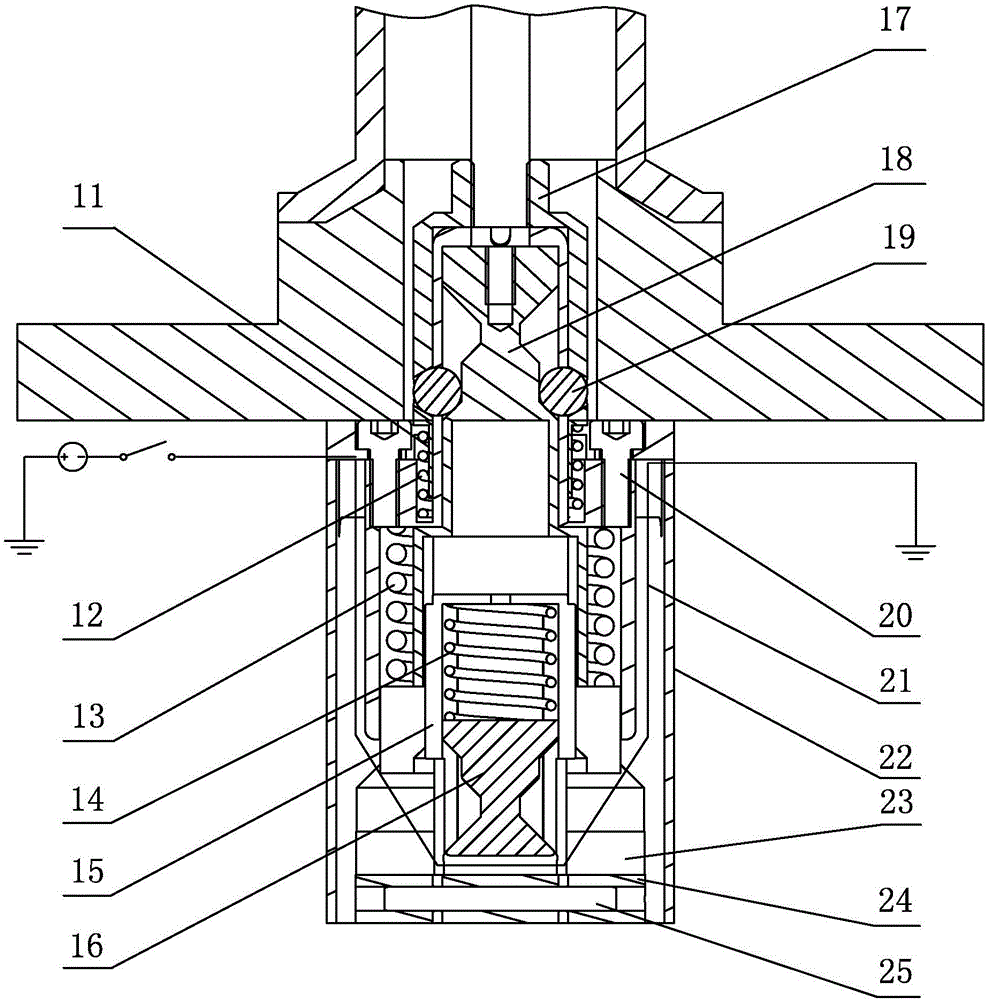

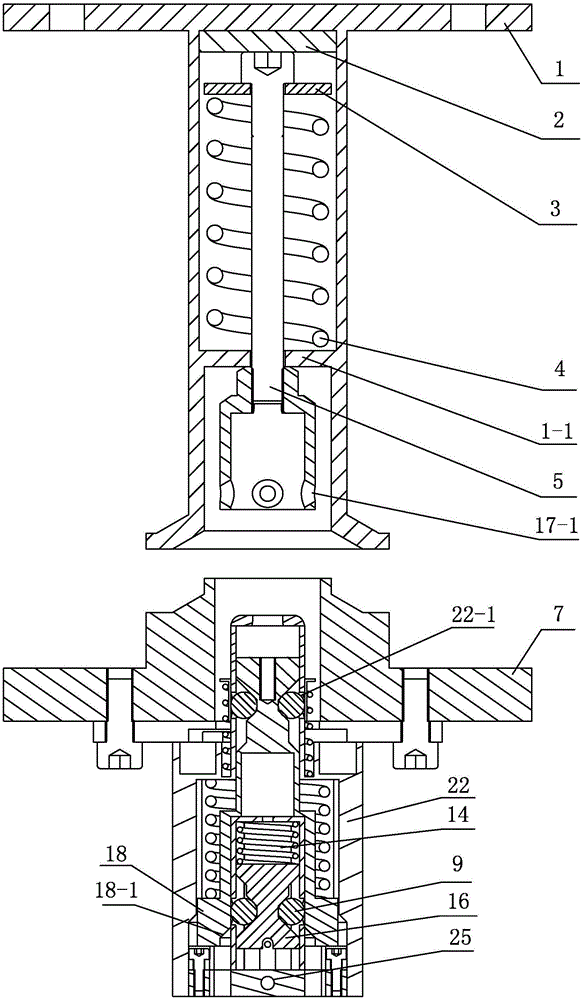

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] see Figure 1-Figure 4 As shown, an ejection release device driven by an SMA wire includes a separation body 1, a separation compression spring 4, a threaded rod 5, a connecting body 7, a lower limit steel ball 9, a limit compression spring 12, a drive compression spring 13, a reset Compression spring 14, steel ball cage 15, sliding bolt 16, connecting sleeve 17, pin bolt 18, upper limit steel ball 19, shape memory alloy wire 21, outer shell 22 and lower end cover 24;

[0026] The pin bolt 18 is a hollow pin bolt, the top of the pin bolt 18 has an annular groove that can accommodate the upper limit steel ball 19, and the sliding bolt 16 has an annular groove that can accommodate the lower limit steel ball 9; the upper end of the outer shell 22 is installed on the connecting body 7 , the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com