Packaging machine for wine bottle packaging box

A technology for red wine bottles and packaging boxes, applied in the field of packaging machines for red wine bottle packaging boxes, can solve the problems of high packaging cost, unenvironmental materials, low work efficiency, etc., achieve good shock resistance, reduce labor input, and improve packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

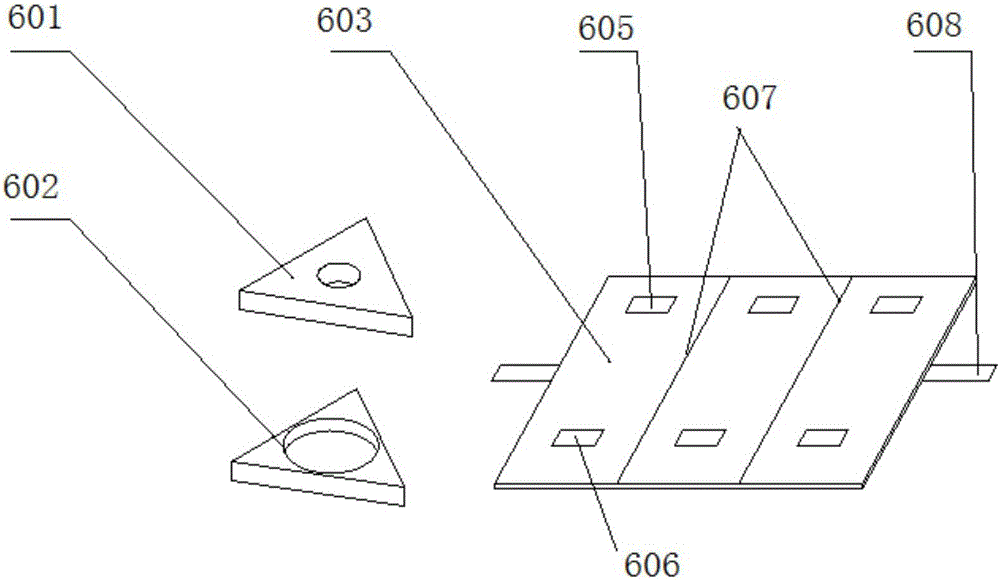

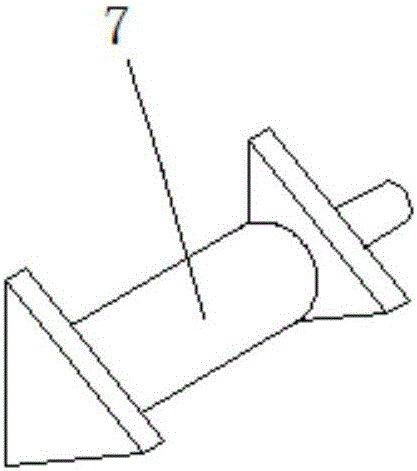

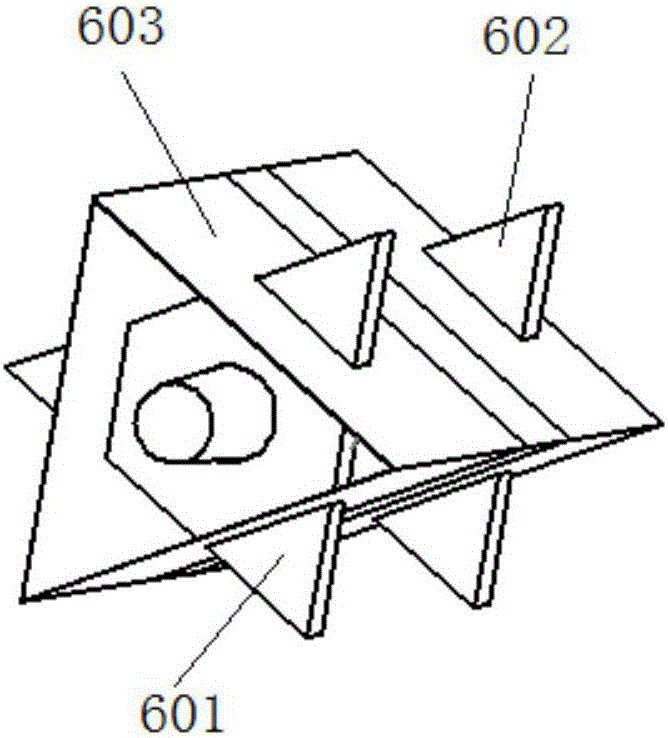

[0029] As shown in the figure, a packaging machine for a red wine bottle packaging box, the red wine bottle packaging box includes a front clamping block 601 for positioning the bottle neck, a rear clamping block 602 for positioning the bottom of the bottle, and a folding plate covering the bottle body from the side 603,

[0030] The front block 601 has a through hole for the bottle neck to pass through, and the rear block 602 has a counterbore for the bottom of the bottle to be inserted, the through hole and the counterbore are coaxially arranged, and the front block 602 The size and shape of 601 and rear block 602 are the same, and both are triangular;

[0031] The folded plate 603 is provided with two creases 607 at intervals along the length direction, and the two creases 607 divide the folded plate into three sub-panels, and the two ends of each sub-panel are respectively provided with sharp points for inserting the front clamping block 601. The first insertion hole 605 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com