Sauce packaging equipment

A technology for packaging equipment and sauces, which is applied in packaging, transportation packaging, transportation and packaging, etc., and can solve the problems of affecting operation efficiency, occupying a large space, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

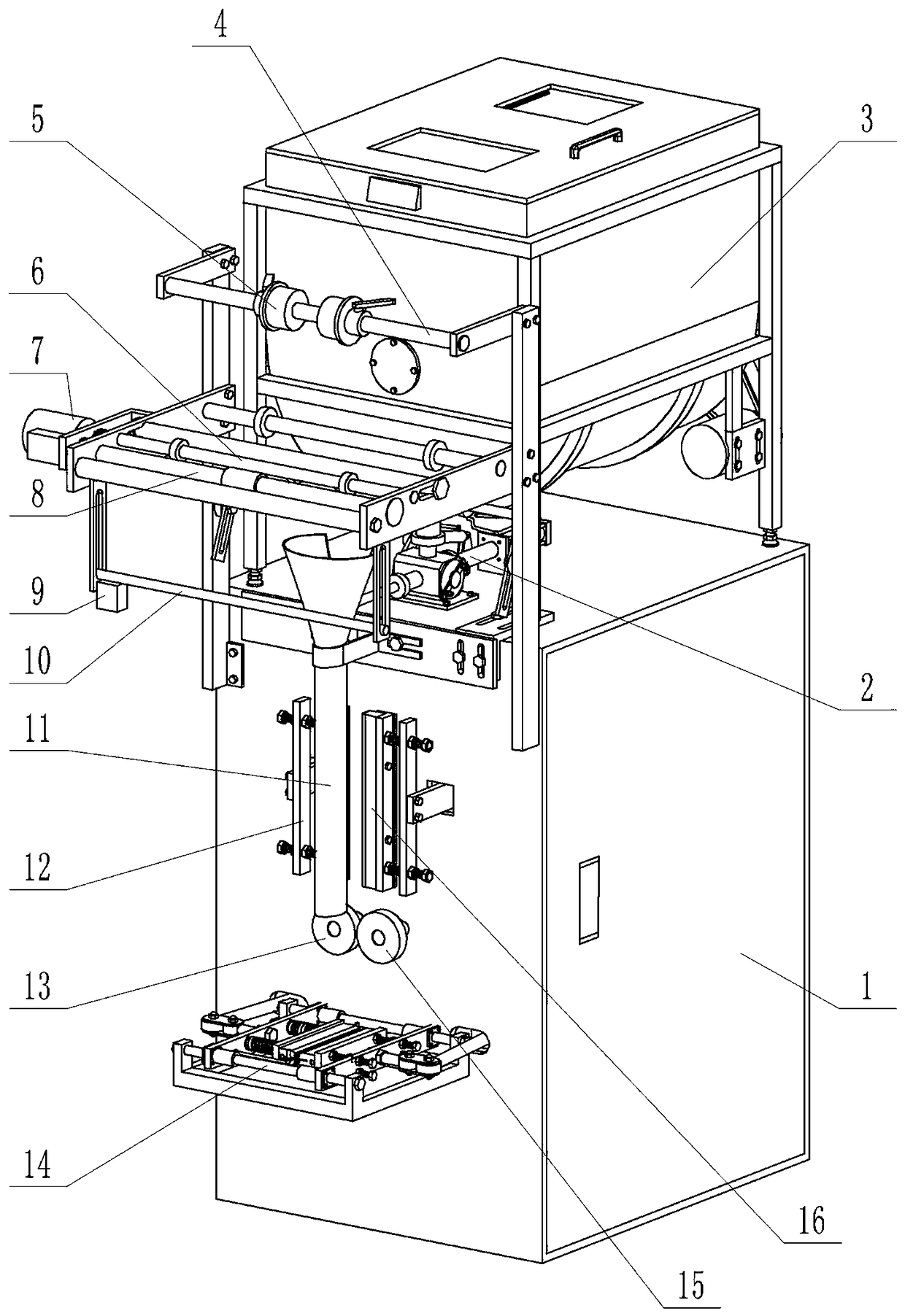

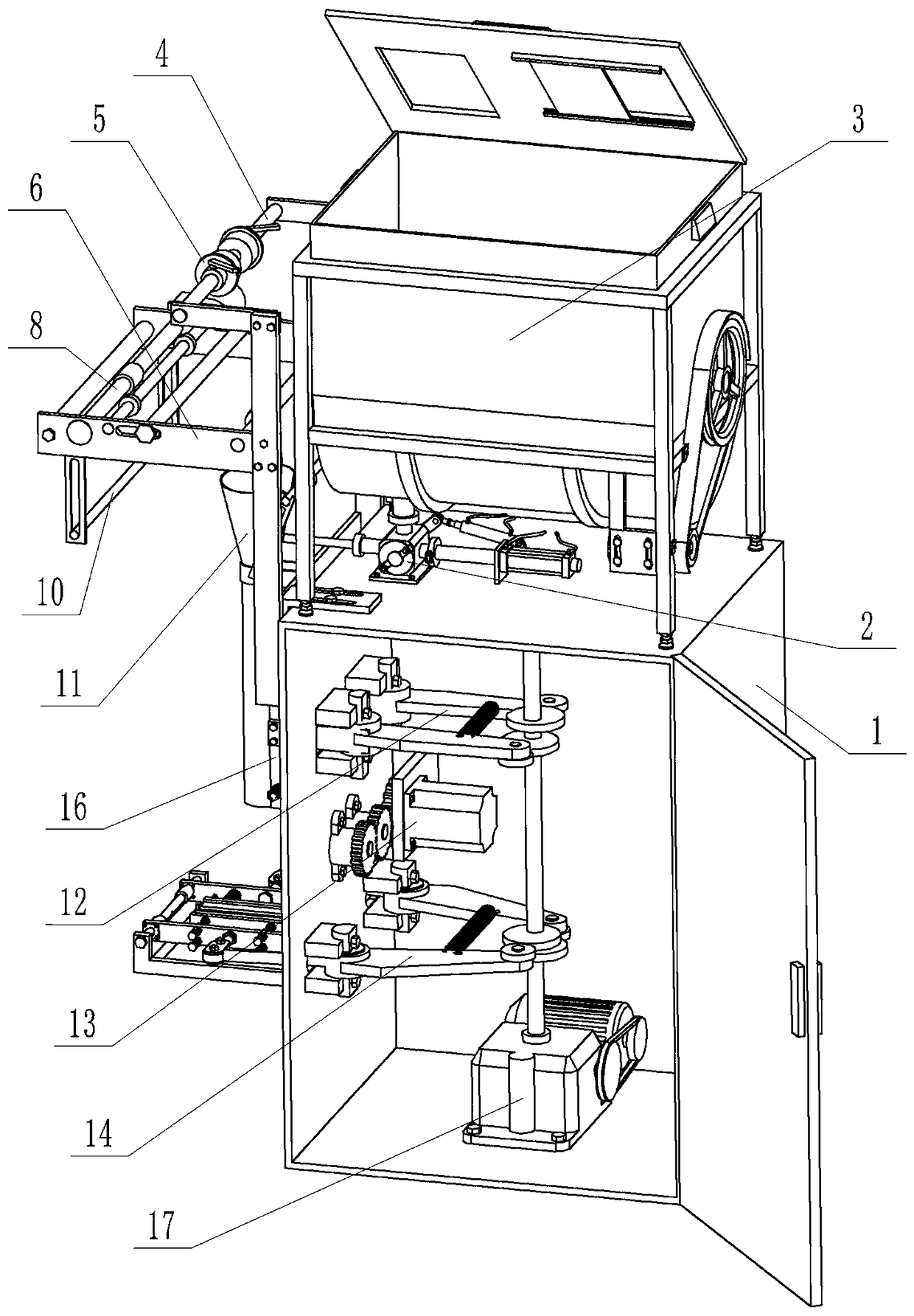

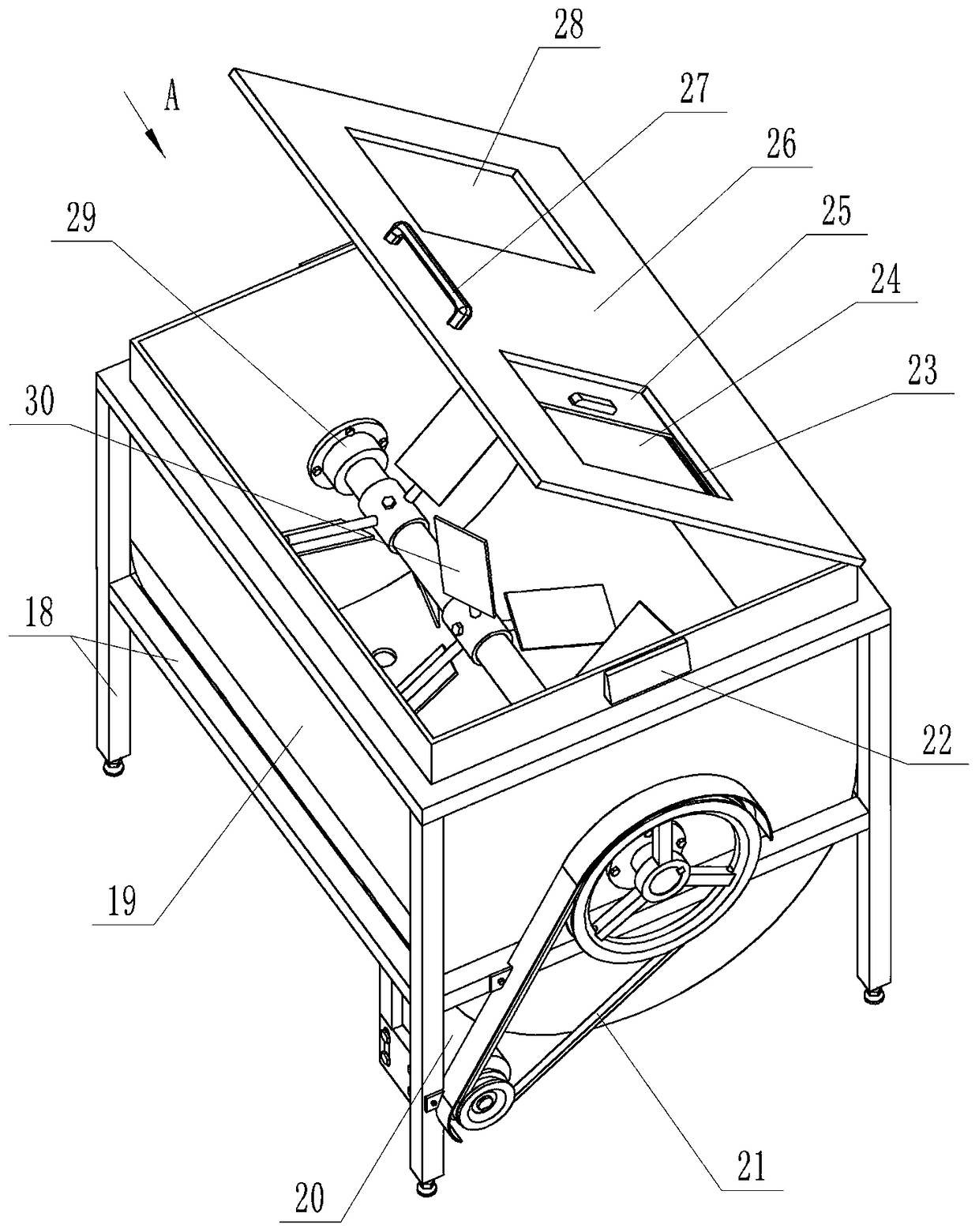

[0034] according to Figure 1-16 The specific structure of the present invention will be described in detail. The sauce encapsulating equipment includes a body 1 with a mechanical structure inside, a feeding device 3 arranged on the top of the body 1 for feeding and stirring, and a device 3 arranged on the front side of the body 1 for fixing the packaging bag film The roll film supporting device 4, the film moving device 6 arranged under the film supporting device 4 for arranging the film of the packaging bag, the packaging funnel 11 arranged under the film moving device 6 for forming the packaging bag film and pouring the sauce (elephant trunk), and a packaging device for heat-sealing the side and bottom edges of the packaging bag film, wherein the film support device 4 arranged above the front side of the fuselage 1 is provided with two film rolls for fixing the film roll Fixed card 5; the film-moving device 6 arranged below the supporting film device 4 includes an unwindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com