Axial-flow underwater three-stage separation method and control system thereof

A three-stage separation and control system technology, applied in separation methods, liquid separation, mining fluids, etc., to achieve the effects of reducing operating energy consumption, efficient separation, and simplified processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

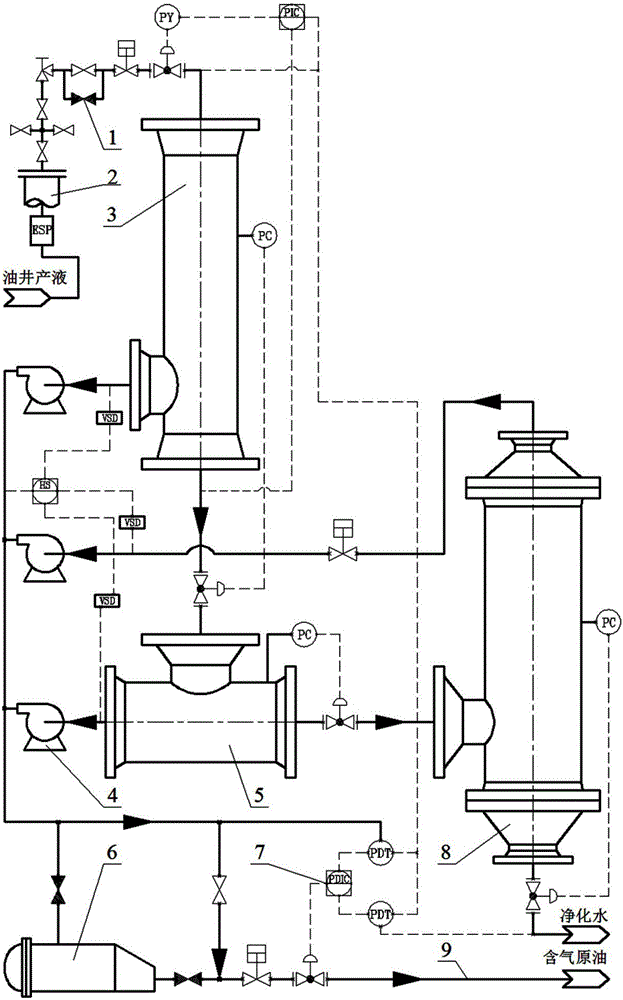

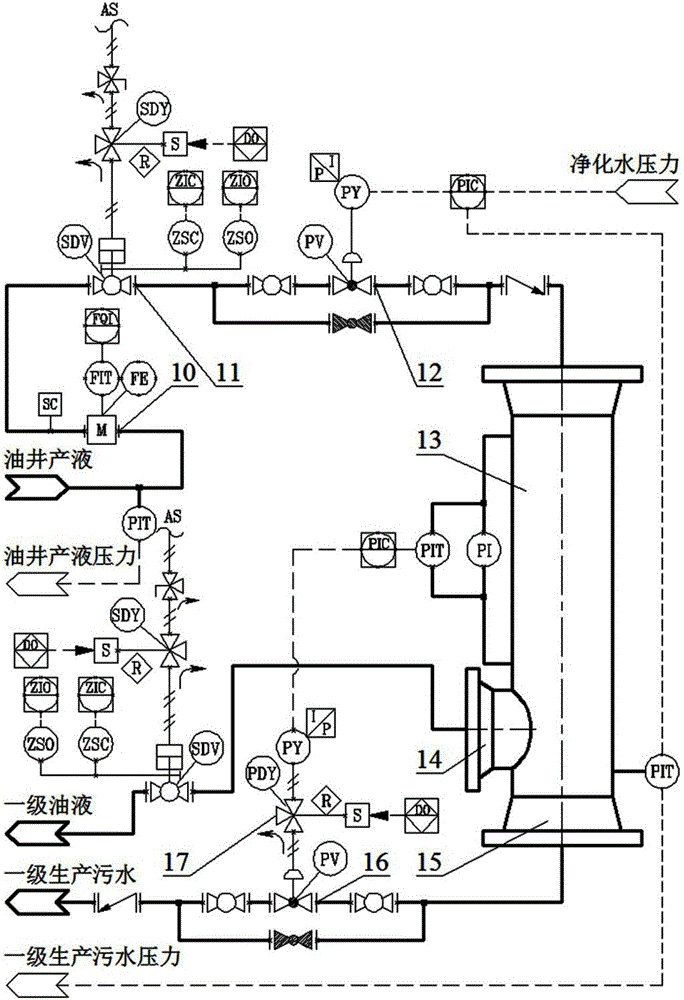

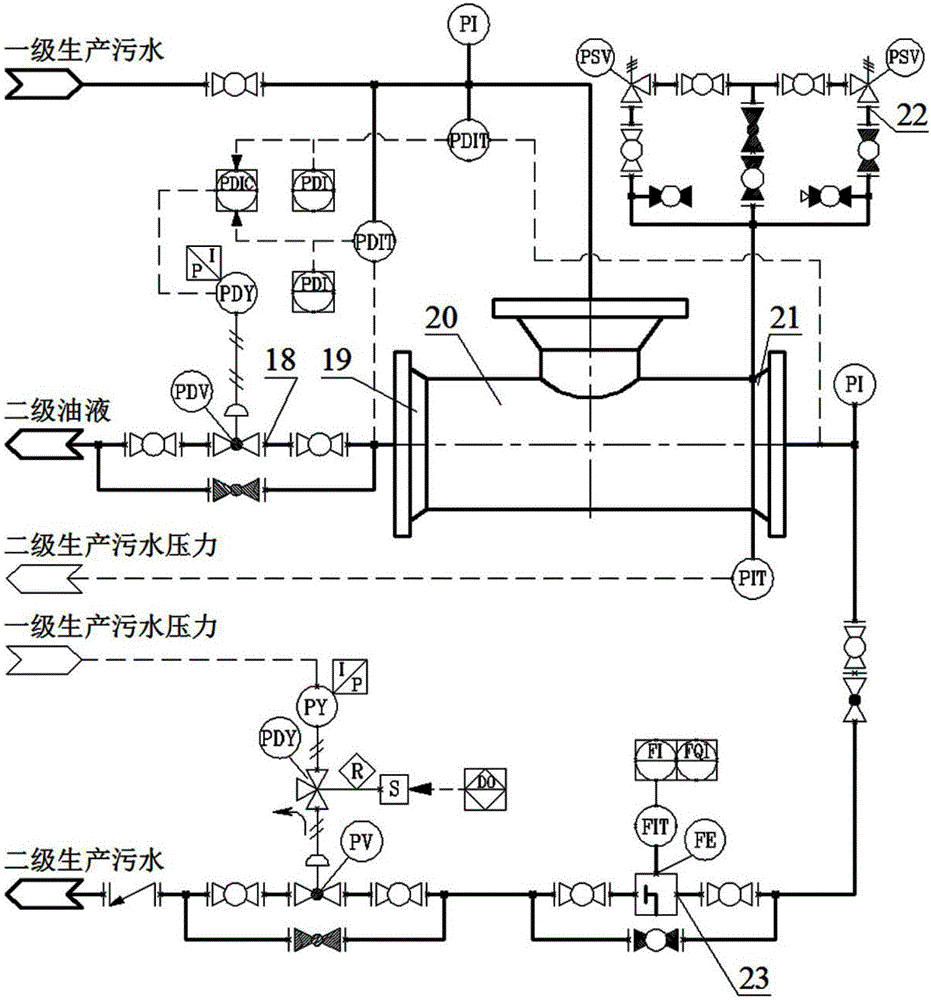

[0028] exist figure 1 Among them, the axial-flow underwater three-stage separation method and its control system mainly include a first-stage separation system 3 , a second-stage separation system 5 , a third-stage separation system 8 , an underwater conveyance system 4 and a separation control system 7 . The inlet of the first-stage separation system 3 is sequentially connected to the subsea tree 2 and the subsea manifold 1 through subsea flowmeters and subsea valves, etc., and the first-stage sewage outlet of the first-stage separation system 3 is controlled by pneumatic control. The underwater valves such as valves are connected to the inlet of the second-stage separation system 5, and the secondary sewage discharge outlet of the second-stage separation system 5 is connected to the inlet of the third-stage separation system 8 through underwater flow meters and underwater valves. , the purified water outlet of the third-stage separation system 8 is connected to the water del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com