Mass-colored emerald green glass and coating manufacturing method thereof

A technology of emerald green glass and body coloring, which is applied in the direction of coating, etc., can solve the problems such as the output and yield of coated glass need to be improved, and the coating area is large, so as to ensure the quality of the film layer, reduce exhaust gas emissions, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

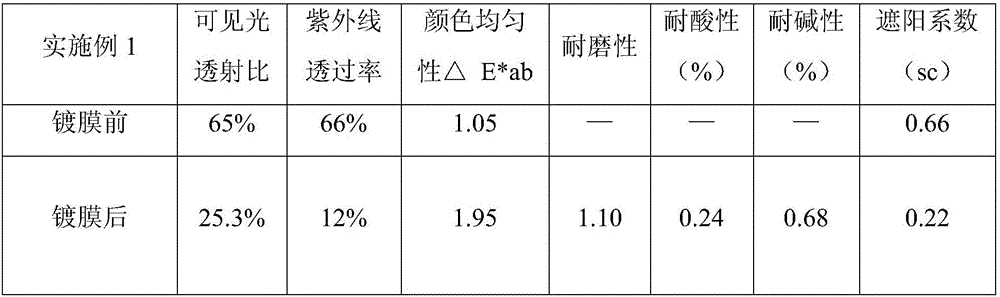

Embodiment 1

[0032] A kind of body coloring emerald green glass (coated glass) of this embodiment, this body coloring emerald green glass comprises glass substrate, contains colorant in the glass substrate, and the main chemical composition of colorant is Fe 2 o3 , CuO and TiO 2 , and their contents are respectively 0.1%, 0.28% and 0.5% of the weight of the glass substrate. One side of the glass substrate is coated with TiO 2 plating, the TiO 2 The coating is a three-layer coating that is sequentially coated on the glass substrate in a laminar flow manner, among which TiO 2 The total thickness of the coating is 700 nm, and the thickness of the glass substrate is 3.6 mm.

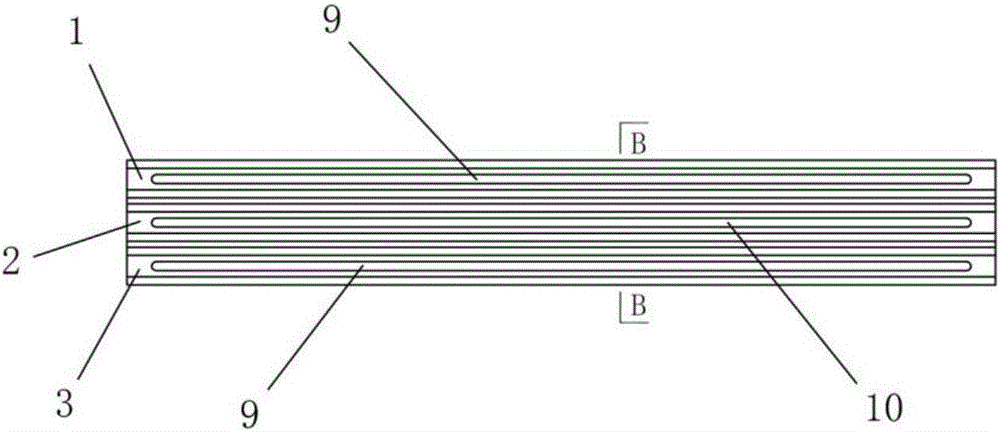

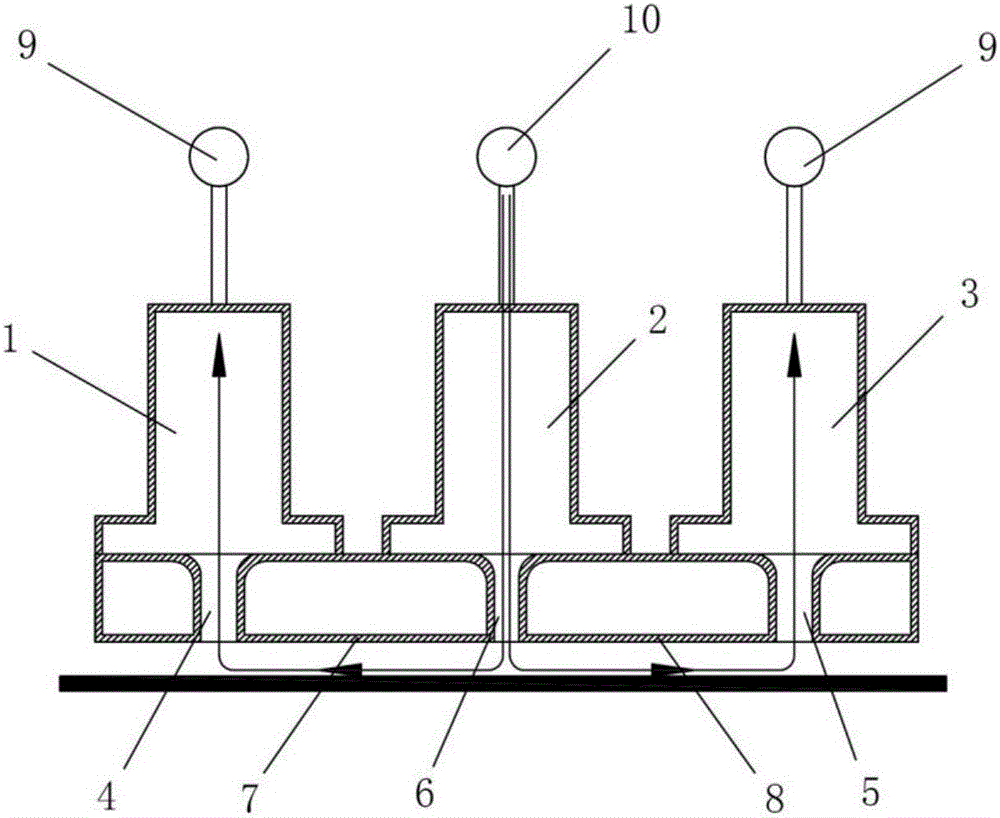

[0033] Such as figure 1 with figure 2 As shown, the coating device used to produce the body-colored emerald green glass of this embodiment includes a first row of waste cavities 1, an air inlet cavity 2 and a second row of waste cavities 3 arranged side by side in sequence. The first row of waste cavities 1 and the ...

Embodiment 2

[0040] A body-colored emerald green glass of this embodiment, the body-colored emerald green glass includes a glass substrate, the glass substrate contains a colorant, and the main chemical composition of the colorant is Fe 2 o 3 , CuO and TiO 2 , and their contents are respectively 0.08%, 0.1% and 0.3% of the weight of the glass substrate. One side of the glass substrate is coated with TiO 2 plating, the TiO 2 The coating is a three-layer coating that is sequentially coated on the glass substrate in a laminar flow manner, among which TiO 2 The total thickness of the coating is 800 nm, and the thickness of the glass substrate is 6 mm.

[0041] Such as figure 1 with figure 2 As shown, the coating device used to produce the body-colored emerald green glass of this embodiment includes a first row of waste cavities 1, an air inlet cavity 2 and a second row of waste cavities 3 arranged side by side in sequence. The first row of waste cavities 1 and the second row of waste ca...

Embodiment 3

[0044] A body-colored emerald green glass of this embodiment, the body-colored emerald green glass includes a glass substrate, the glass substrate contains a colorant, and the main chemical composition of the colorant is Fe 2 o 3 , CuO and TiO 2 , and their contents are respectively 0.09%, 0.19% and 0.4% of the weight of the glass substrate. One side of the glass substrate is coated with TiO 2 plating, the TiO 2 The coating is a three-layer coating that is sequentially coated on the glass substrate in a laminar flow manner, among which TiO 2 The total thickness of the coating is 750 nm, and the thickness of the glass substrate is 4.8 mm.

[0045] Such as figure 1 with figure 2 As shown, the coating device used to produce the body-colored emerald green glass of this embodiment includes a first row of waste cavities 1, an air inlet cavity 2 and a second row of waste cavities 3 arranged side by side in sequence. The first row of waste cavities 1 and the second row of waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com