Production equipment for naphthalene water reducer

A naphthalene-based water reducer and production equipment technology, applied in the field of naphthalene-based water reducer production equipment, can solve problems such as poor stirring devices, affecting the quality of the water reducer, and insufficient reaction of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

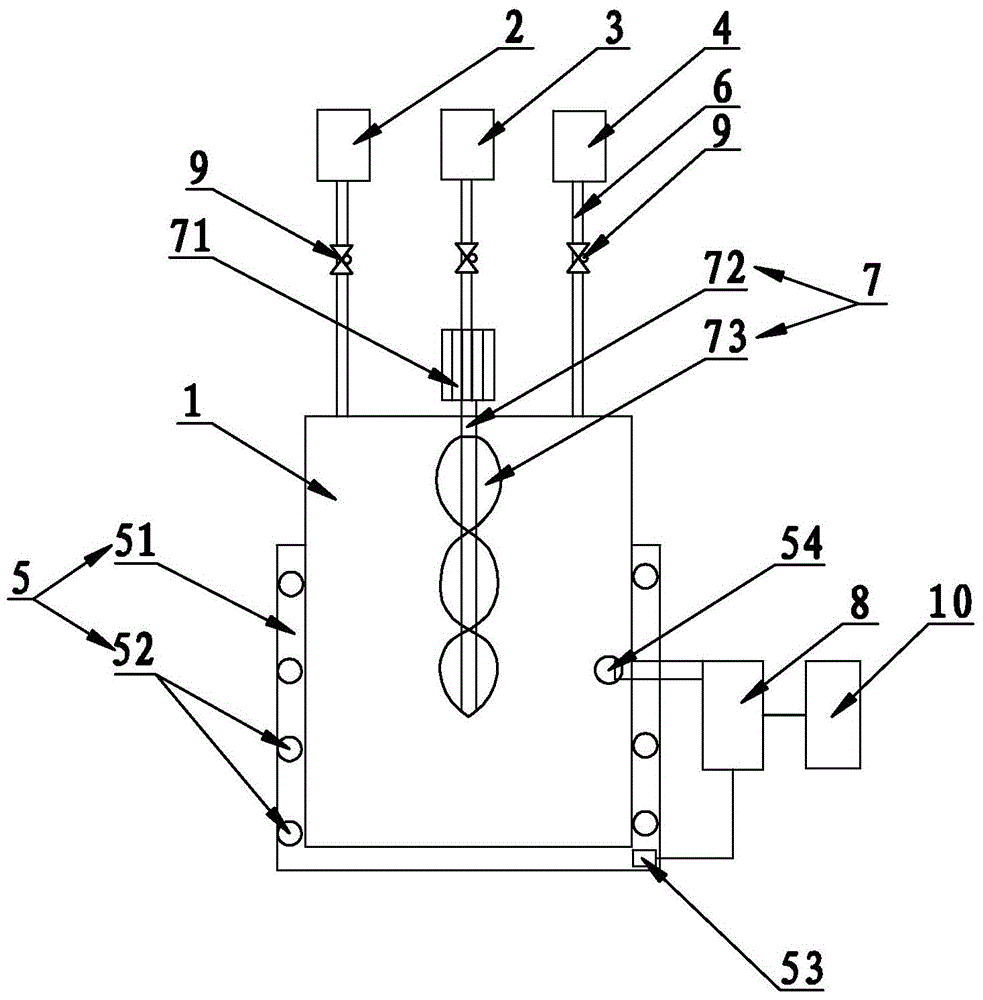

[0023] Such as figure 1 As shown, a production equipment of naphthalene-based water reducer, including a reaction kettle 1, a raw material tank 2, a raw material tank 2 3, a raw material tank 3 4, a heat preservation device 5, a feeding pipe 6, a stirring device 7, and a control system 8 and display 10; the outer side of the bottom of the reaction kettle 1 is provided with the heat preservation device 5, and the heat preservation device 5 includes a heat preservation interlayer 51, a steam pipe 52, a temperature sensor 53 and a temperature regulator 54, and the heat preservation interlayer 51 is provided with The steam pipe 52 for heating, the steam pipe 52 is spirally wound on the outside of the reaction kettle 1; The temperature regulator 54 on the outside is connected; the raw material tank one 2, raw material tank two 3, and raw material tank three 4 are placed above the reactor 1, and pass through the feeding pipe 6 and the reactor 1 respectively. Internal communication,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com