Method for producing organic composite fertilizer by utilizing iron phosphate to efficiently catalyze straws

A technology of iron phosphate and compound fertilizer, which is applied in the direction of organic fertilizer, application, fertilization device, etc., can solve the problems of little use and ineffective utilization of straw, achieve less side components, improve the quality of agricultural products, and have good physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

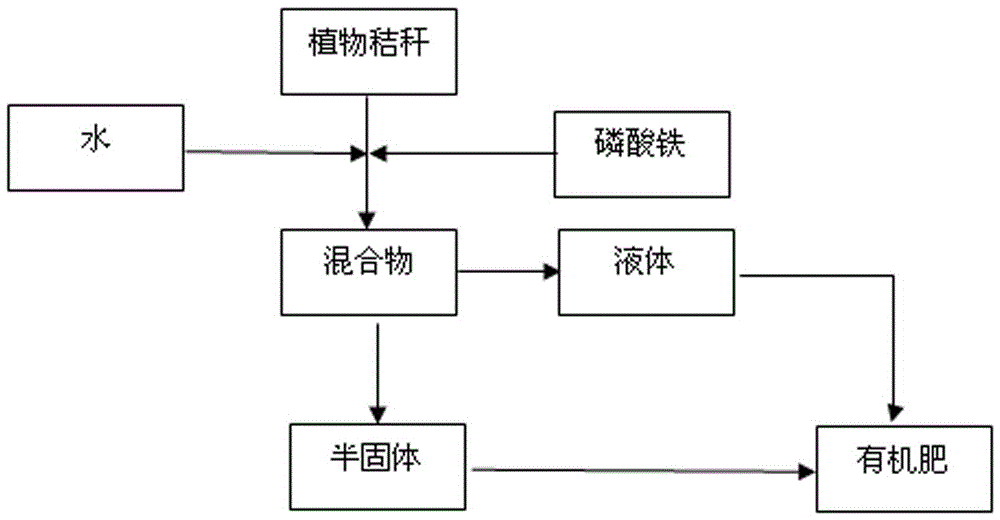

Method used

Image

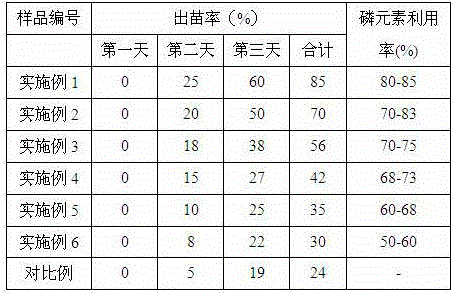

Examples

Embodiment 1

[0021] Break the freshly harvested sunflower straw to 5mm, weigh 30g and mix it with distilled water 1:1 (w / w), then add 0.9g (90%) iron phosphate to the mixture, send the mixture into an anaerobic fermentation tank, and control the temperature The temperature is 50°C, and the production of compound fertilizer is carried out, and the reaction time is 3 days. The obtained compound fertilizer is naturally dried until the moisture content is 25% to 30%, and then simply packed. Fertilizer efficiency was tested by pot experiments.

Embodiment 2

[0023] Break the freshly harvested barley straw to 20mm, weigh 30g and mix it with distilled water 1:1.5 (w / w), then add 1.5g (92%) of iron phosphate to the mixture, send the mixture into an anaerobic fermentation tank, and control the temperature The temperature is 45°C, and the production of compound fertilizer is carried out, and the reaction time is 4 days. The obtained compound fertilizer is naturally dried until the moisture content is 25% to 30%, and then simply packed. Fertilizer efficiency was tested by pot experiments.

Embodiment 3

[0025] Crush the freshly harvested wheat straw to 30mm, weigh 30g and mix it with distilled water 1:2 (w / w), then add 2.1g (94%) of iron phosphate to the mixture, send the mixture into an anaerobic fermentation tank, and control the temperature The temperature is 40°C, and the production of compound fertilizer is carried out, and the reaction time is 5 days. The obtained compound fertilizer is naturally dried until the moisture content is 25% to 30%, and then simply packed. Fertilizer efficiency was tested by pot experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com