High-gloss low-warp polycarbonate reinforced flame-retardant material

A technology of polycarbonate and flame retardant materials, applied in the field of flame retardant material preparation, can solve the problems of restricting the use of light and thin appearance parts of products, reducing the heat resistance and impact resistance of materials, and the decline of ABS resin flame retardant performance, etc., to achieve Improvement of floating fiber and flame retardancy, improvement of product surface and warpage, and improvement of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

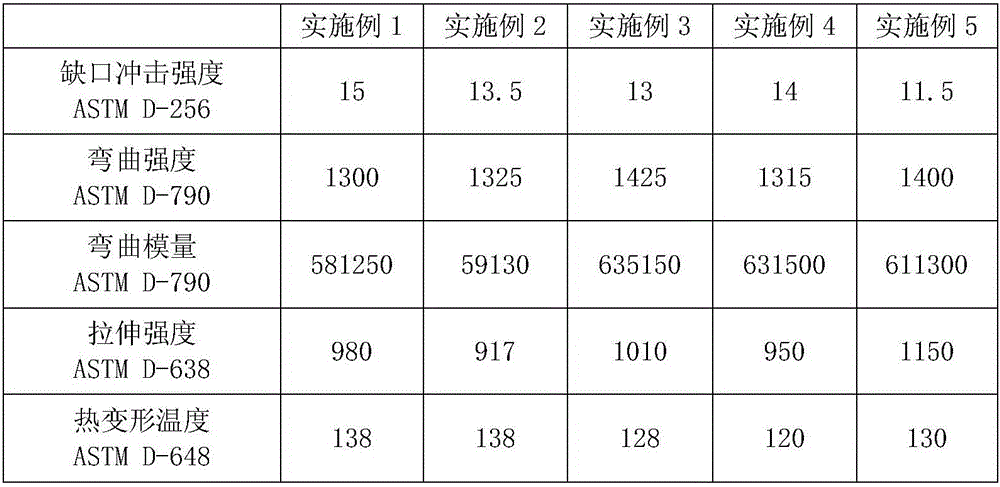

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0039] A high gloss and low warpage polycarbonate reinforced flame retardant material of the present invention comprises the following components by weight percentage:

[0040] Aromatic polycarbonate 30-70%;

[0041] Siloxane PC 10-30%;

[0042] Inorganic mineral filler 5-30%;

[0043] Anti-dripping agent 0.1-2%;

[0044] Silicone 0.1-5%;

[0045] Glass fiber 5-30%;

[0046] Sulfonate flame retardant 0.06-1.0%;

[0047] Antioxidant 0.3%;

[0048] CBT fluidity improver 0.5-10%.

[0049] Aromatic polycarbonate itself has excellent comprehensive performance. After glass fiber and mineral modification, the surface and processing performance of the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com