Long-afterglow luminescent material and preparation method thereof

A long-lasting luminescence and compound technology, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of different decay times of long-lasting phosphors, and achieve the effects of stable chemical properties, simple preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of the above long afterglow luminescent material, comprising the following steps:

[0032] A) K-containing compounds, Na-containing compounds, Li-containing compounds, M-containing compounds, R-containing compounds, Ga-containing compounds, Al-containing compounds, Ge-containing compounds, Si-containing compounds and Bi-containing compounds Compounds are mixed and ground to obtain a mixture;

[0033] B) Sintering the mixture to obtain a long-lasting luminescent material.

[0034] In the present invention, the compound containing K, the compound containing Na, the compound containing Li, the compound containing M, the compound containing R, the compound containing Ga, the compound containing Al, the compound containing Ge, the compound containing Si and the compound containing Compounds of Bi are mixed and ground to obtain a mixture;

[0035] Wherein, the K-containing compound is potassium carbonate or potassium ...

Embodiment 1

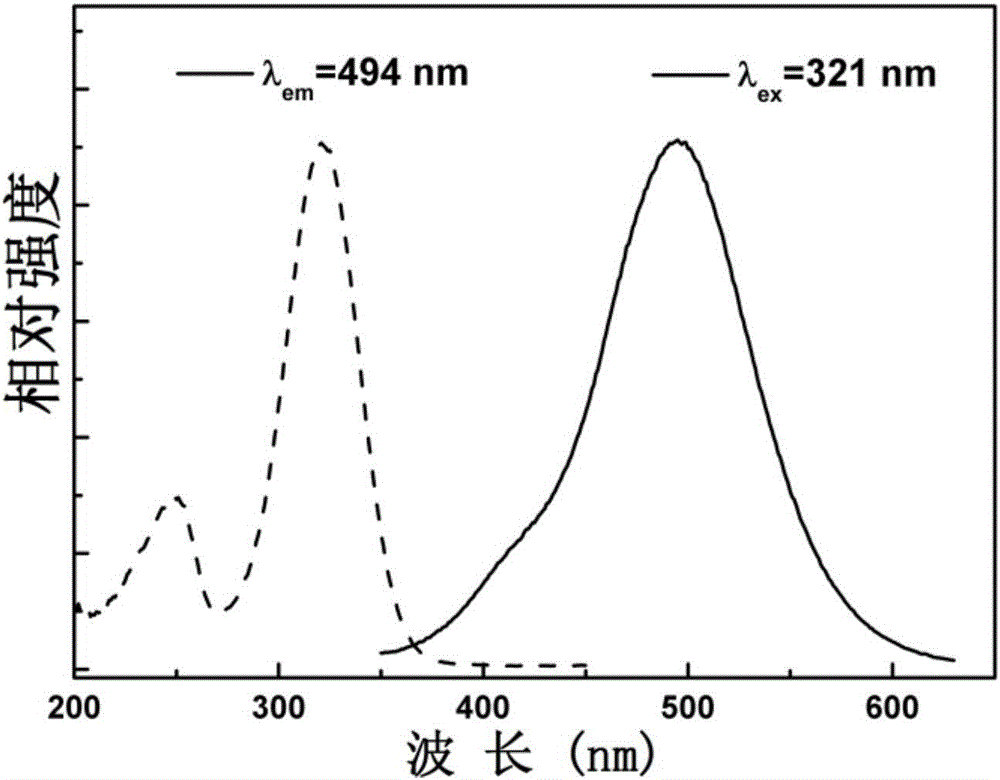

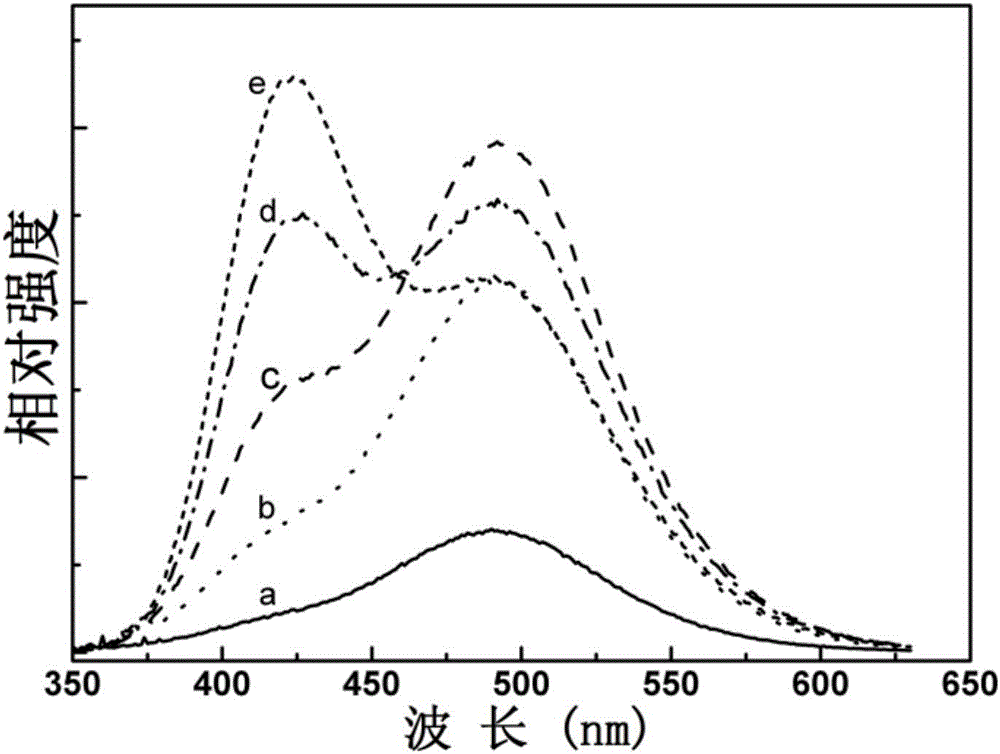

[0047] Will K 2 CO 3 (analytical pure), Ga 2 o 3 (analytically pure), GeO 2 (analytical pure) and Bi 2 o 3 (99.99%) as raw materials, the molar ratio between them is 0.495:0.5:1:0.005, accurately weigh the above substances, and fully grind them evenly in an agate mortar, put them into a corundum crucible, and heat them in a high temperature furnace at 1200 ℃ for 3 hours, naturally cooled to room temperature, and then ground to obtain a white powder sample whose chemical composition is K 0.99 GaGeO 4 :0.01Bi 3+ . Its excitation and emission spectra are figure 2 shown. After the sample is excited by 254nm ultraviolet light, it emits a cyan long afterglow, image 3 a is the afterglow spectrum, the main peak is located near 495nm. And the test results show that the afterglow time of the sample can reach 5h (>0.32mcd / m 2 ).

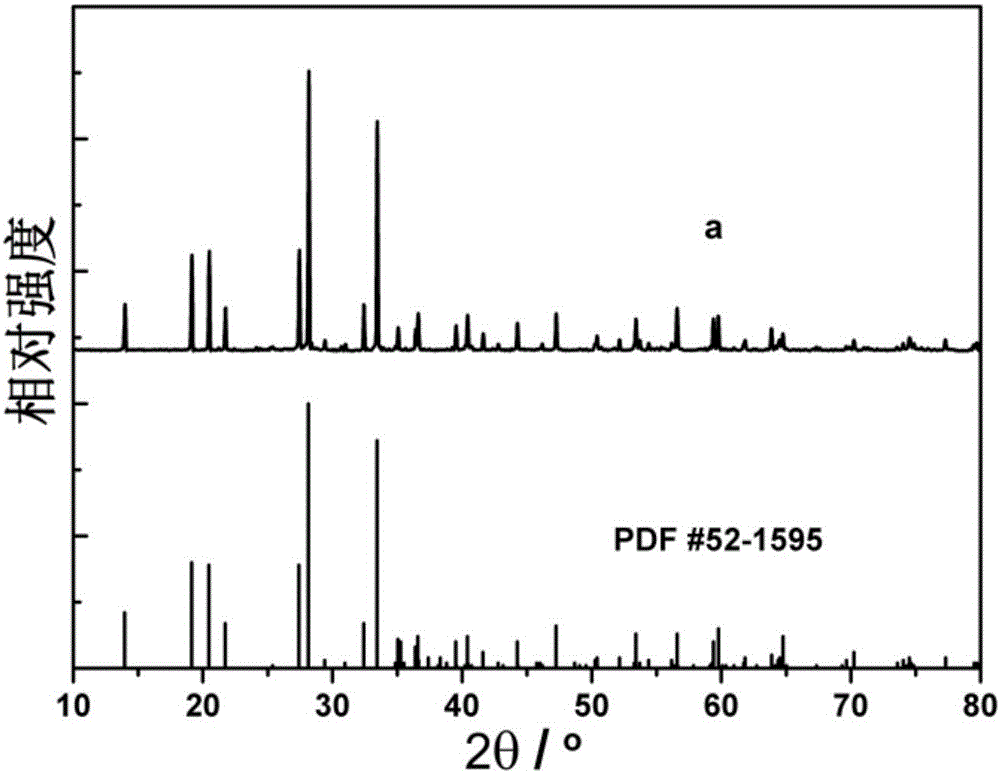

[0048] Carry out X-ray diffraction analysis to the sample that embodiment 1 obtains, instrument used is German Bruker / D8-FOCUS X-Ray Diffractom...

Embodiment 2

[0053] Will K 2 CO 3 (analytical pure), Ga 2 o 3 (analytically pure), GeO 2 (analytical pure) and Bi 2 o 3 (99.99%) as raw materials, the molar ratio between them is 0.49995:0.5:1:0.00005, accurately weigh the above substances, and fully grind them evenly in an agate mortar, put them into a corundum crucible, and place them in a high temperature furnace at 1100 ℃ roasting for 6 hours, naturally cooled to room temperature, and then ground to obtain a white powder sample, whose chemical composition is K 0.9999 GaGeO 4 :0.0001Bi 3+ . The XRD diffraction pattern, fluorescence spectrum and afterglow spectrum properties of the long-lasting luminescent material are similar to those of Example 1. Afterglow time up to 3h (>0.32mcd / m 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com