A kind of transparent long afterglow glass ceramics and its preparation method

A technology of glass-ceramics and long afterglow, which is applied in the field of solid luminescent materials, can solve the problems of poor physical and chemical stability of phosphate glass, limit the actual application environment, and poor luminous performance, and achieve stable physical and chemical properties, low cost, and good transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also relates to a method for preparing the above-mentioned transparent long-lasting glass-ceramics, the method includes a two-step melt quenching method, and the steps are as follows:

[0036] Step (1) will P 2 O 5 , SiO 2 , BaO, SrO, CaO, ZnO, Al 2 O 3 , La 2 O 3 , Na 2 O, Li 2 O.B 2 O 3 、 Bi 2 O 3 , Sb 2 O 3 The powder raw material is weighed according to the composition ratio, heated and kept warm to melt it, and obtain the bulk precursor glass;

[0037] Step (2) Grinding the precursor glass obtained in step (1) into powder, adding SrAl 2 O 4 :Eu, Dy long afterglow powder is further ground, heated and kept warm to melt it to obtain block glass-ceramics.

[0038] Preferably, the method steps are as follows:

[0039] (1) will P 2 O 5 , SiO 2 , BaO, SrO, CaO, ZnO, Al 2 O 3 , La 2 O 3 , Na 2 O, Li 2 O.B 2 O 3 、 Bi 2 O 3 , Sb 2 O 3 The powder raw materials are weighed according to the proportion of the components, grou...

Embodiment 1

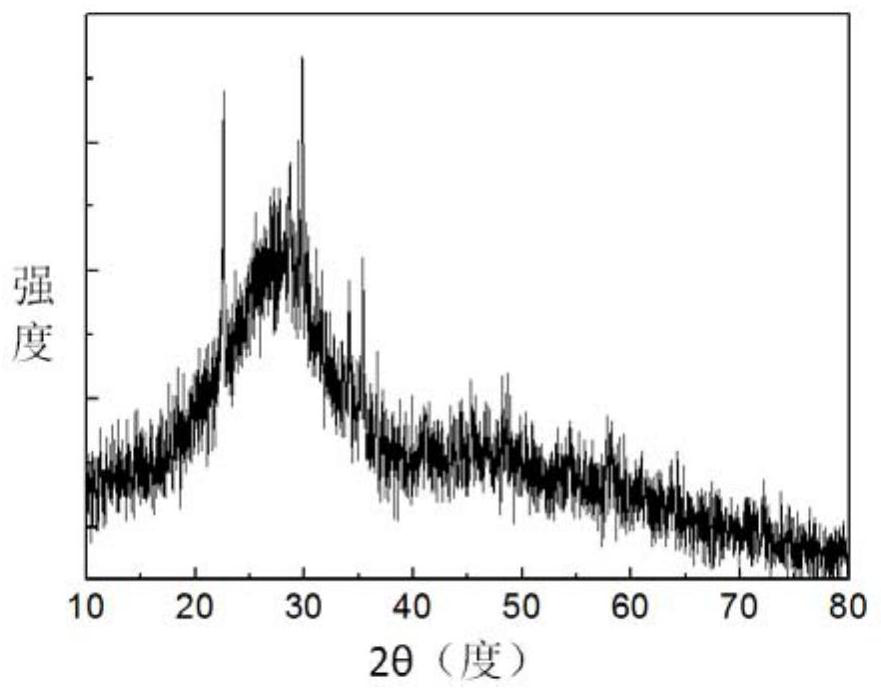

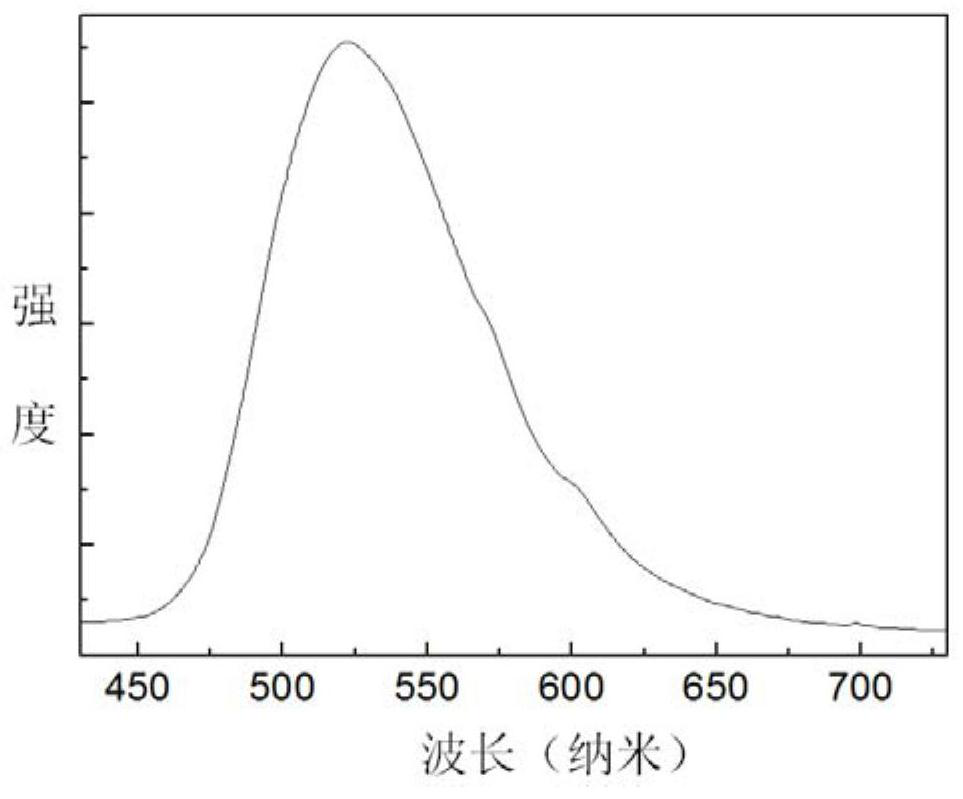

[0042] Example 1: P 2 O 5 , SiO 2 , BaO, SrO, CaO, ZnO, Al 2 O 3 , La 2 O 3 , Na 2 O, Li 2 O.B 2 O 3 、 Bi 2 O 3 , Sb 2 O 3 Powder raw materials according to 35P 2 O 5 -20SiO2 2 -10BaO-2SrO-2CaO-8ZnO-2Al 2 O 3 -1La 2 O 3 -5Na 2 O-5Li 2 O-6B 2 O 3 -2Bi 2 O 3 -2Sb 2 O 3 (mol%) After weighing the proportioning ratio, mix the raw materials evenly, pour them into a crucible, and heat up to 1050° C. for 1 hour in a resistance furnace to melt it. Then, the glass solution is quickly poured into a copper mold and cooled to form a transparent precursor glass. Then, the precursor glass was ground into powder, and 7wt% SrAl 2 O 4 :Eu, Dy long-lasting powder mixed evenly, placed in a resistance furnace at 850°C for 1 hour, then the glass melt was taken out and quickly poured into a copper mold to form a transparent long-lasting glass-ceramic. After cessation of light, it exhibits a long green afterglow.

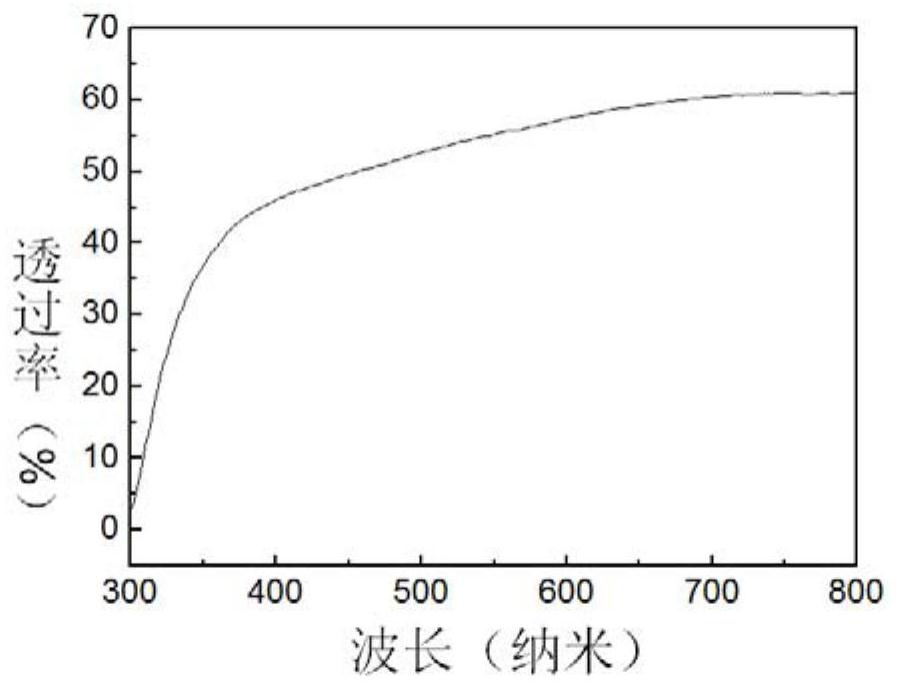

[0043] figure 1 The medium transmittance curve shows ...

Embodiment 2

[0044] Example 2: P 2 O 5 , SiO 2 , BaO, SrO, CaO, ZnO, Al 2 O 3 , La 2 O 3 , Na 2 O, Li 2 O.B 2 O 3 、 Bi 2 O 3 , Sb 2 O 3 Powder raw materials according to 25P 2 O 5 -25SiO2 2 -10BaO-2SrO-3CaO-8ZnO-2Al 2 O 3 -2La 2 O 3 -6Na 2 O-6Li 2 O-7B 2 O 3 -2Bi 2 O 3 -2Sb 2 O 3 (mol%) After weighing the proportioning ratio, the raw materials were mixed evenly, poured into a crucible, and heated to 1020° C. for 1 hour in a resistance furnace to melt it. Then, the glass solution is quickly poured into a copper mold to form a transparent precursor glass. Then, the precursor glass was ground into powder, and 10wt% SrAl 2 O 4 : Mix Eu and Dy long-lasting powders evenly, place them in a resistance furnace at 830°C for 1 hour, then take out the glass melt and quickly pour it into a copper mold to form a transparent long-lasting glass-ceramic with maximum light transmittance 66%, which exhibits a green long afterglow. The emission wavelength of the prepared glass-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com