Method for manufacturing polrvinyl chloride/europium-doped strontium aluminate photoluminescent sheets

A technology of polyvinyl chloride and photoluminescence, which is applied in the direction of luminescent materials, chemical instruments and methods, and flat products, and can solve the problems of poor stability of rare earth organic small molecule complexes, restrictions on the application of rare earth luminescent materials, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

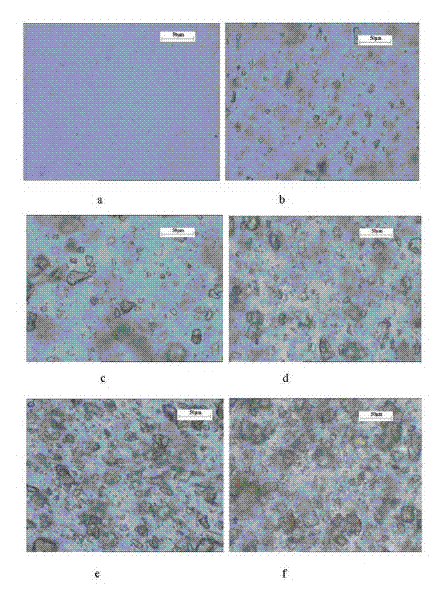

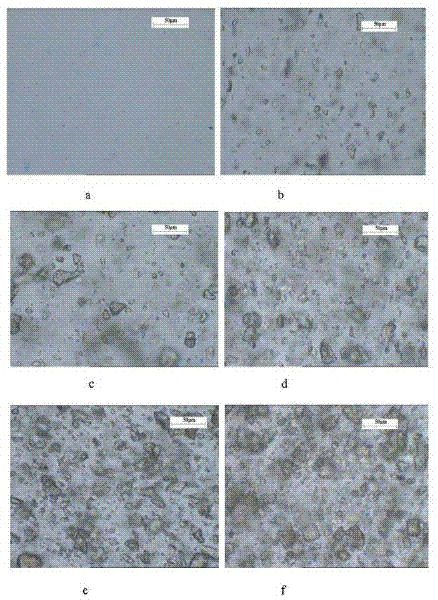

Image

Examples

Embodiment 1

[0096] Provide a kind of manufacture method of polyvinyl chloride / strontium aluminate photoluminescent sheet of the present invention below, comprise the steps:

[0097] ① Ingredients

[0098] Accurately weigh 86 parts by weight of polyvinyl chloride resin according to the formula, 7 parts by weight of strontium aluminate europium luminescent powder, 4 parts by weight of PVC impact modifier LB-717, 0.5 parts by weight of PVC processing aid HL-301p, methyl mercaptan Base tin SW-997 1.0 parts by weight, PVC external slip agent ZB-74 0.5 parts by weight, PVC internal slip agent W-16 0.9 parts by weight, pigment 0.058 parts by weight, calcium stearate 0.042 parts by weight;

[0099] ② mixed

[0100] High mixing temperature ℃ 100~110

[0101] Low mixing temperature ℃ 50~65

[0102] ③ extrusion

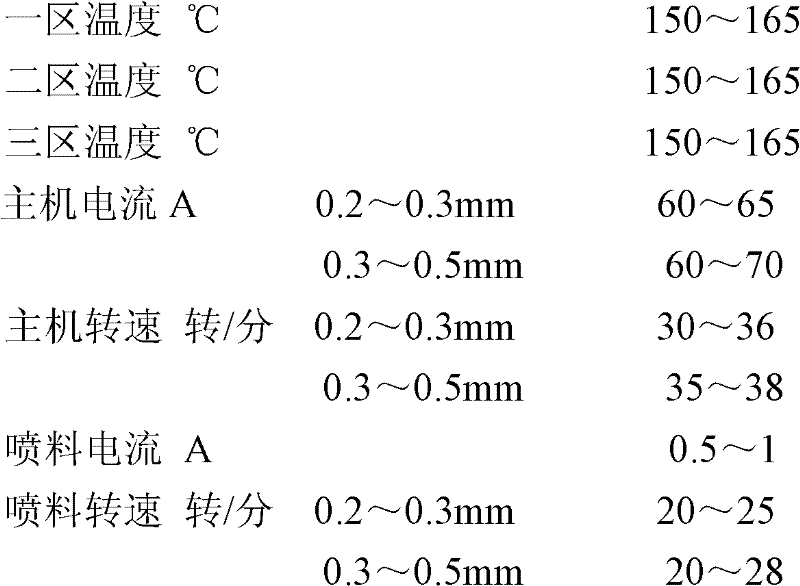

[0103] The process conditions are as follows:

[0104] Zone 1 temperature ℃ 150~165

[0105] Zone 2 temperature ℃ 150~165

[0106] Three zone temperature ℃ 150~165 ...

Embodiment 2~ Embodiment 7

[0141] According to the method and steps of Example 1, process and manufacture polyvinyl chloride / strontium aluminate europium photoluminescent sheet according to the formula in Table 1

[0142] Table 1

[0143] raw material Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 PVC 85 86 85. 84. 85 86 Strontium aluminate europium luminescent powder 6 4 7. 6. 8 5 PVC impact modifier LB-717 6 5 4 6 4 5 PVC processing aid HL-301p 0.5 1.5 1.5 0.5 0.5 1 Methyltin Mercaptide SW-977 1 1.5 1 1.5 1 1 PVC slip agent ZB-74 0.5 0.91 0.5 1. 0.9 1 PVC inner slip agent W-16 0.91 1 0.89 0.9 0.54 0.9 pigment 0.04 0.05 0.08 0.06 0.03 0.07 Calcium stearate 0.05 0.04 0.03 0.04 0.03 0.03

[0144] The polyvinyl chloride / strontium aluminate europium photoluminescence sheet material that embodiment 2~embodiment 7 manufactures reaches following technical index:

[0145] ① A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com