A temperature management method for a blast furnace body

A management method and blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as low data utilization, inability to intuitively reflect furnace conditions, and inefficient real-time temperature data management, to simplify work and ensure inoperability. the effect of reducing the load on the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

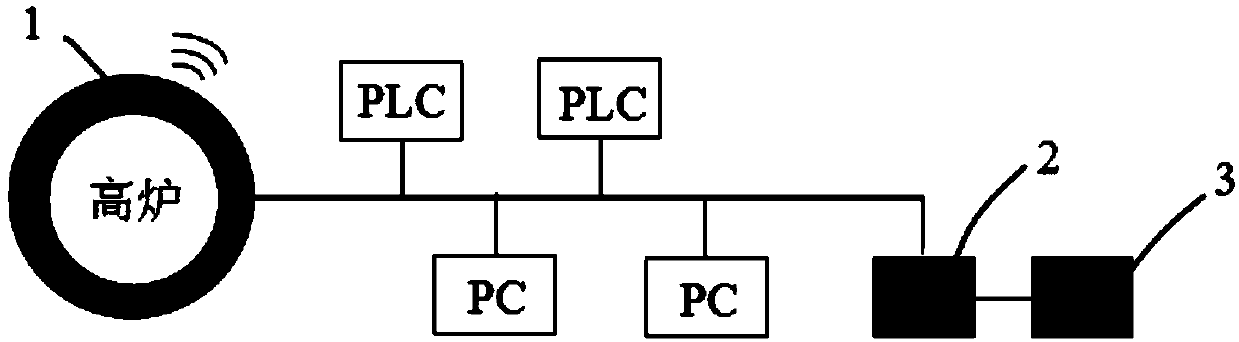

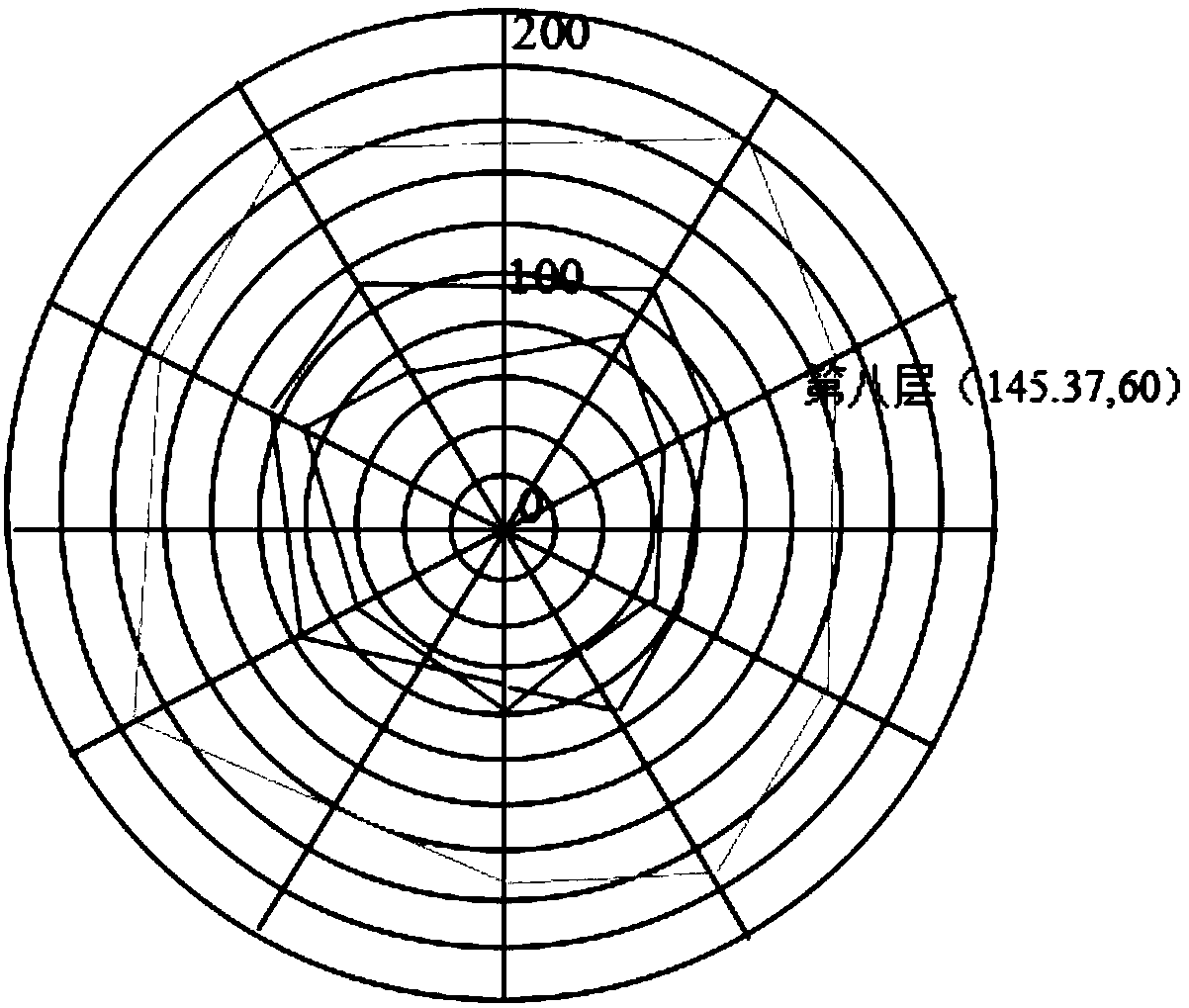

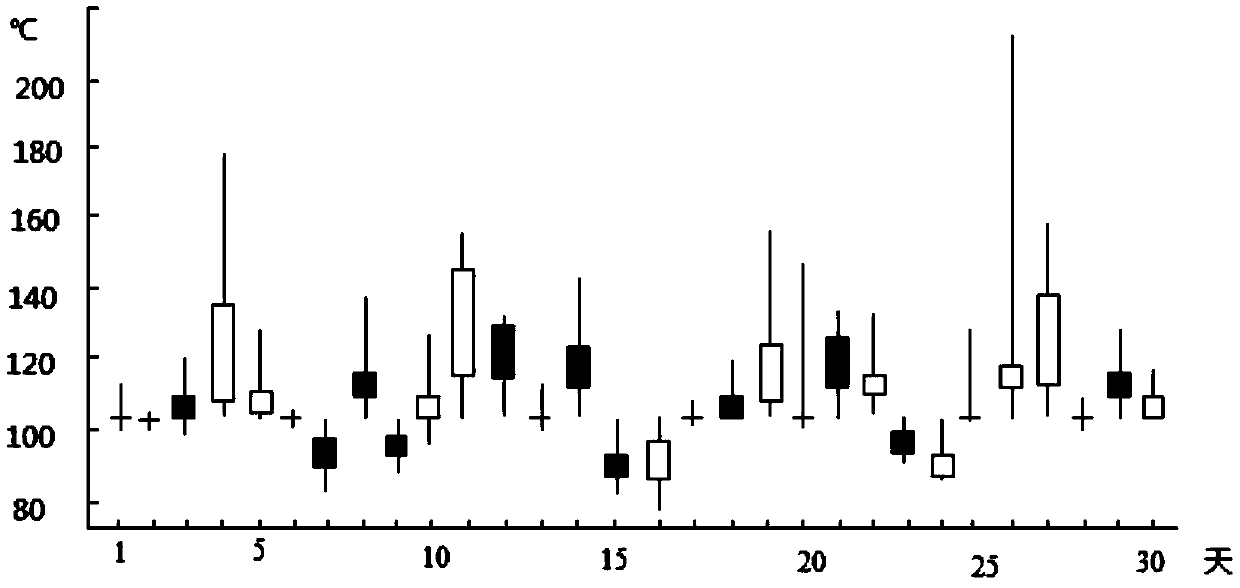

[0056] combine figure 1 , a blast furnace body temperature management system in this embodiment, comprising a blast furnace temperature monitoring system 1, a data processing center 2 and an image display system 3, the blast furnace temperature monitoring system 1 is connected to the data processing center 2, and the data processing center 2 is connected to the image display system The system 3 is connected, the blast furnace temperature monitoring system 1 transmits the temperature data of the blast furnace shaft to the data processing center 2, the data processing center 2 performs data analysis and processing, draws corresponding images, and transmits them to the image display system 3 for display.

Embodiment 2

[0058] A blast furnace body temperature management system in this embodiment includes a blast furnace temperature monitoring system 1, a data processing center 2 and an image display system 3, the blast furnace temperature monitoring system 1 is connected to the data processing center 2, and the data processing center 2 is connected to the image display system 3 connection, the blast furnace temperature monitoring system 1 transmits the temperature data of the blast furnace shaft to the data processing center 2, and the data processing center 2 performs data analysis and processing, draws corresponding images, and transmits them to the image display system 3 for display.

[0059] The blast furnace temperature monitoring system 1 includes a temperature sensor and a wireless signal transmitter, the temperature sensor and the wireless signal transmitter are located on the cooling wall in the furnace shell, and the temperature sensor is connected to the wireless signal transmitter. ...

Embodiment 3

[0061] A blast furnace shaft temperature management system in this embodiment is similar to Embodiment 2, wherein the temperature sensor is a nickel-constantan thermocouple, and the collected data is transmitted to the data processing center through a wireless signal transmitter. The nickel-constantan thermocouple converts the temperature change of the touch into a voltage difference signal for transmission. It has the characteristics of large temperature measurement range, high sensitivity, good stability, and long service life. Its life can last for a generation of furnace life, avoiding the blast furnace The replacement of thermocouples during the furnace service period simplifies work and improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com