Sectional assembling and mounting method for converter vaporization flue

A technology of vaporizing flue and installation method, which is applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve the problems of pollution, endangering human health and agricultural production, interfering with power grid TV and communication, etc., to reduce costs. , Improve the risk of installation management and control, reduce the effect of shift and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

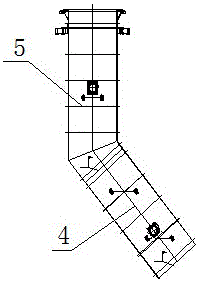

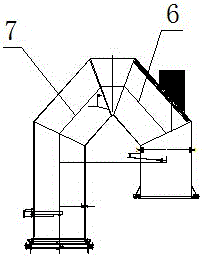

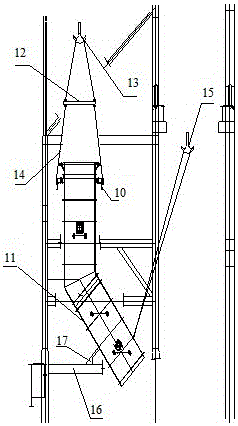

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further specifically described below through specific examples, but the present invention is not limited to the examples.

[0042] A method for segmentally combined installation of a converter vaporization flue according to the present invention is characterized in that the installation method includes the following steps:

[0043] Step 1. Construction preparation;

[0044] 1.1 The production site is flat and compacted, which meets the site level conditions for segmental assembly of vaporization cooling flue;

[0045] 1.2 Welding equipment enters the site, and materials for the sealing measures of the vaporization flue during the welding process are all in place;

[0046]1.3 Carry out welding procedure qualification for materials in accordance with the regulations, issue welding operation instructions, and disclose welding procedures;

[0047] 1.4 The welding consumables are stored in a special warehouse, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com