A temperature field device for vertical hvpe growth equipment

A vertical, equipment technology, applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of high equipment height, large space occupation, instability, etc., to improve quality and reduce equipment manufacturing costs , the effect of temperature field stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

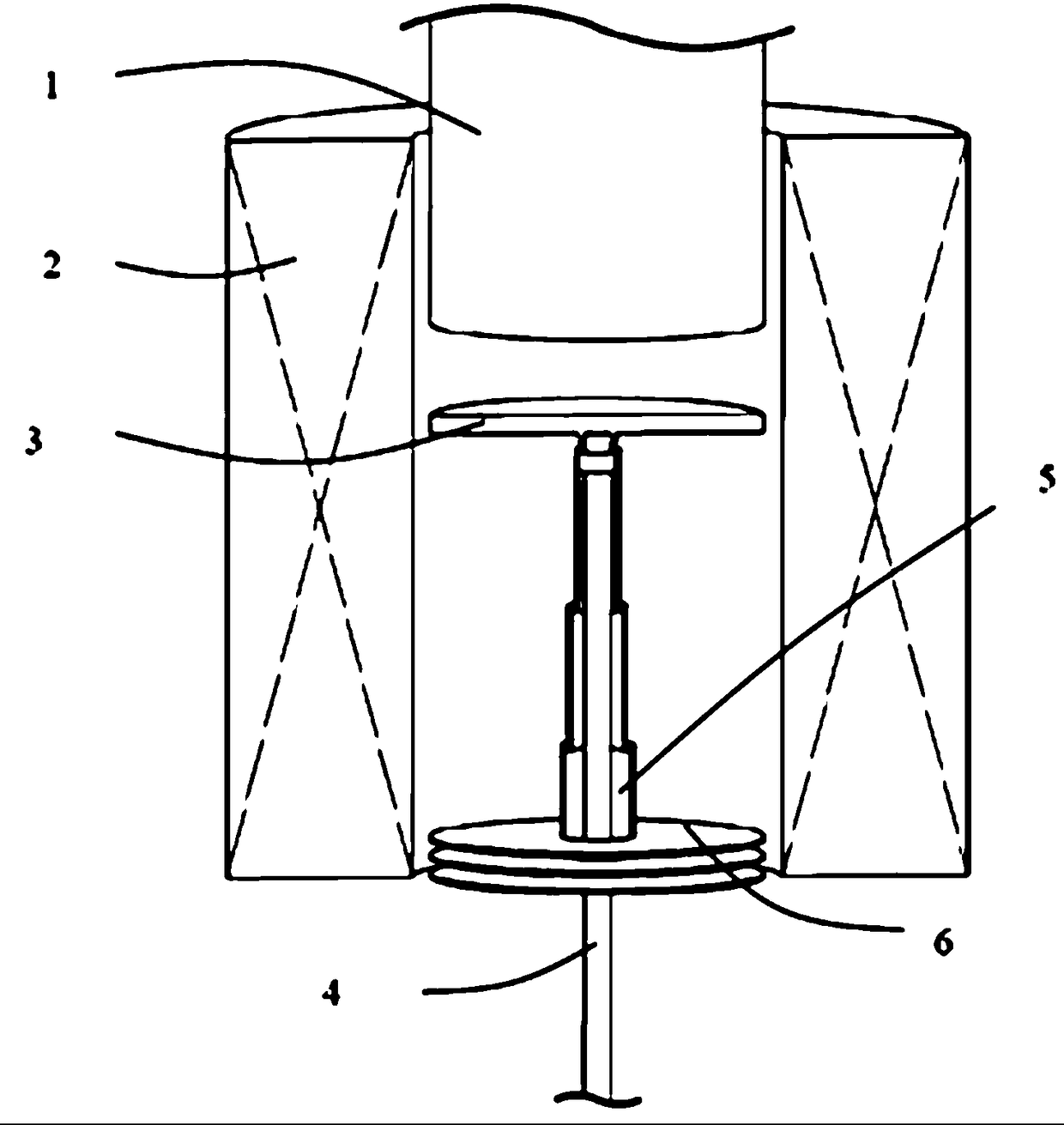

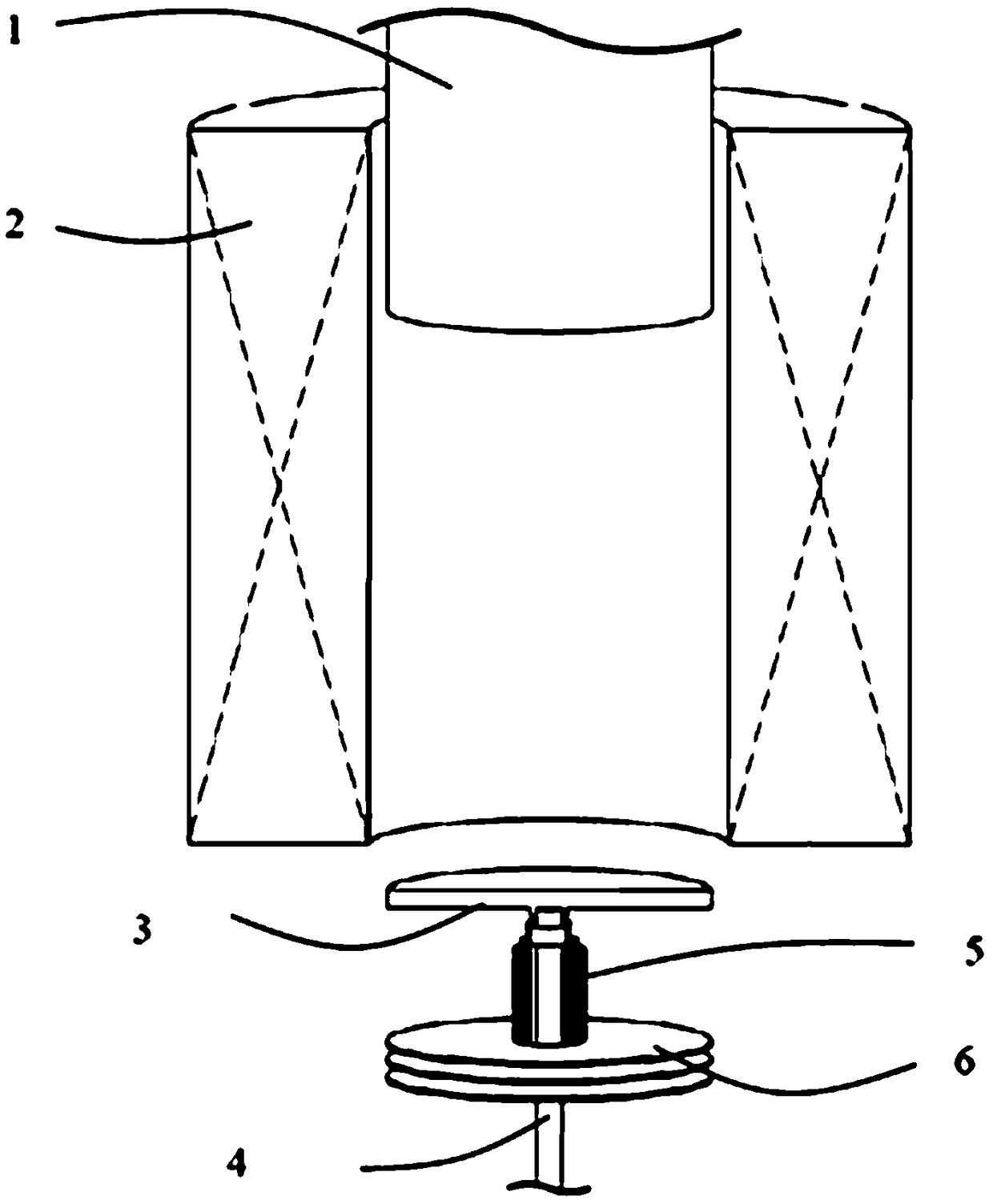

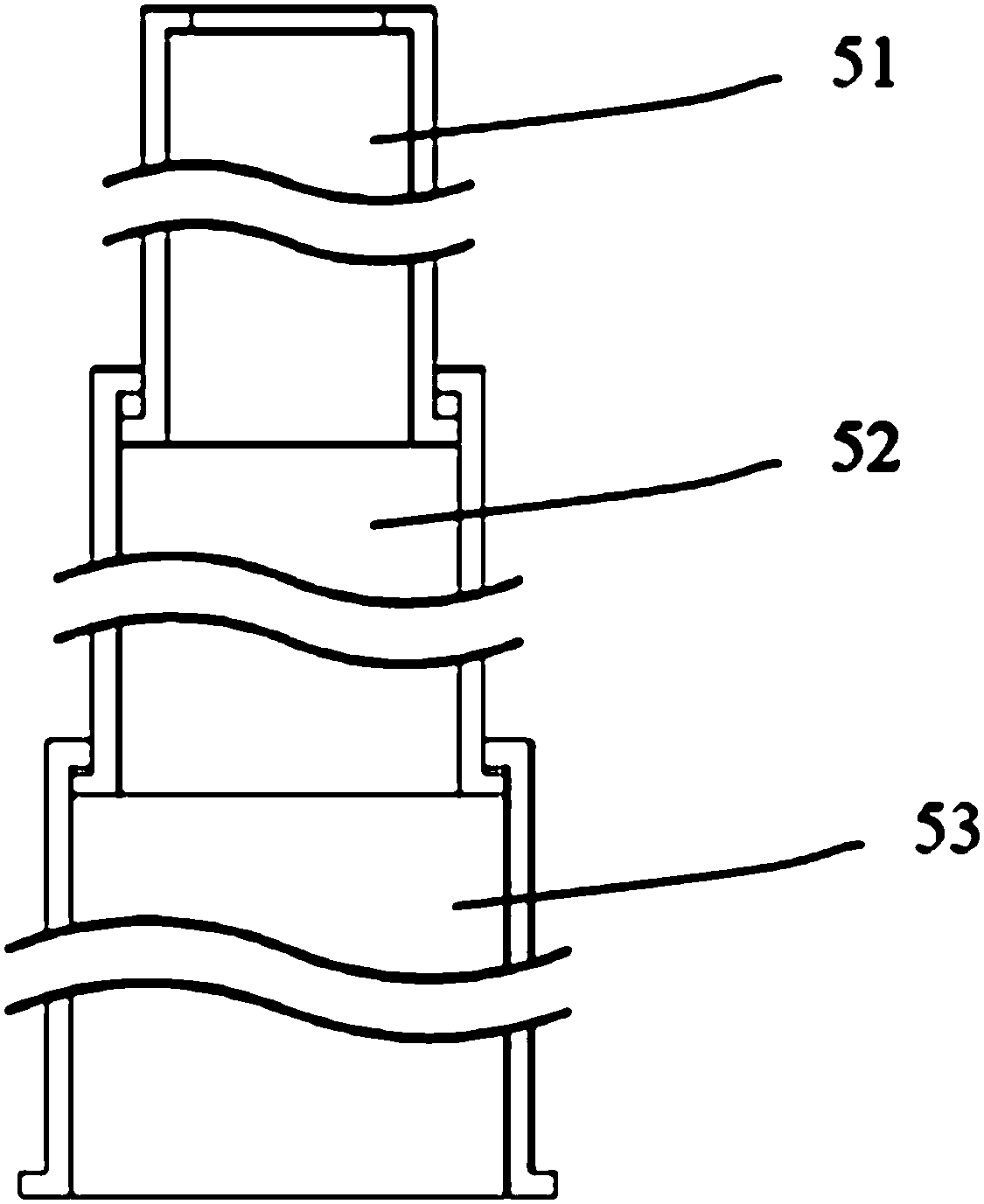

[0025] Embodiment one, as attached Figure 1-3 As shown, the telescopic connector is a sleeve connector 5, which includes a sleeve and a flange, and the sleeve connector 5 is movably connected by at least two sleeves. The uppermost sleeve is connected to the upper part of the lifting rod 4, and the lowermost sleeve is connected to the heat insulation layer. When the lifting rod 4 moves upward, the sleeve of the sleeve connector 5 moves upward, and the sleeves of each layer are pulled apart. After the sleeve connector 5 is fully pulled apart, the distance between the heat insulation layer 6 and the substrate support plate 3 reaches the maximum, and the heat insulation layer moves upward with the lifting rod 4 , and the sleeve connector 5 Descending together with the heat insulation layer 6, when the heat insulation layer descends to contact with the workbench inside the heater, the heat insulation layer is blocked, the lifting rod continues to descend, and the sleeve connector ...

Embodiment 2

[0027] Embodiment two, as attached Figure 3-6 As shown, the telescopic connector is a chain connector, the chain connector includes a chain 7 and a connecting ring 71, the upper end of the chain is connected to the upper part of the elevating rod 4 through the connecting ring 71, and the connecting ring 71 is fixed on the upper part of the elevating rod 4 Below the substrate support plate 3, the lower end of the chain 7 is connected to the heat insulation layer 6, and the lifting rod 4 can not only lift up and down but also rotate. When the lifting rod 4 rotates up, the chain 7 is straightened, and the substrate support plate 3 and the The distance between the heat insulation layers 6 reaches the maximum, and the heat insulation layer 6 moves upwards with the lifting rod. When the lifting rod rotates and descends, when the heat insulation layer 6 contacts the workbench arranged below the inside of the heater 2, the heat insulation layer 6 is blocked by the workbench and no lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com