Detection device of large-scale section-bar three-dimensional bending component and detection method thereof

A technology of detection device and detection method, applied in the direction of measurement device, mechanical counter/curvature measurement, instrument, etc., can solve the problems of high cost, large floor space, large number of inspection tools, etc., to achieve convenient detection, reduce manufacturing cost and The effect of space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

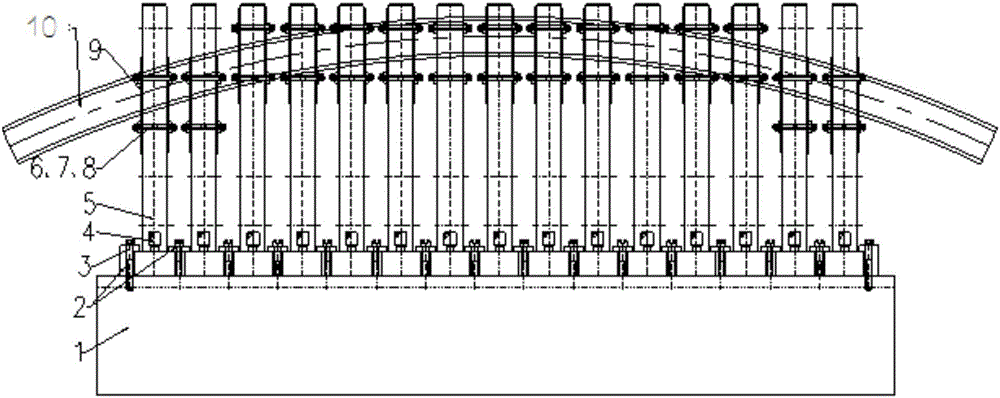

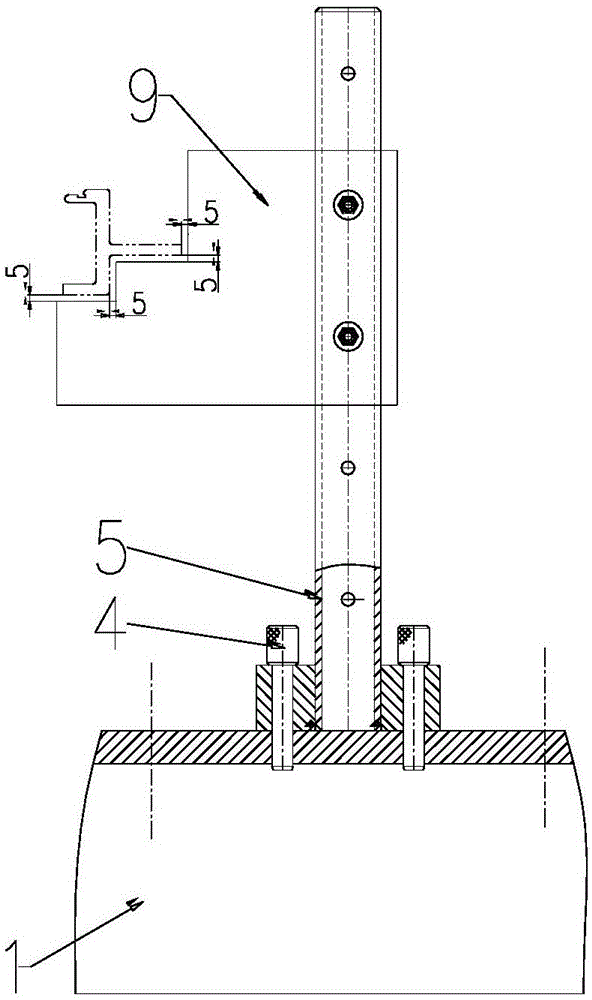

[0054] A detection device for three-dimensional bending parts of large profiles is composed of a detection workbench 1 , 15 height brackets 5 , 27 detection templates 11 and three positioning support templates 9 . The bracket 5 is fixed on the detection workbench 1 , and the detection template 11 and the positioning support template 9 are respectively positioned and installed on the bracket 5 through two equidistant holes on the column. The upper surface of the detection table 1 is a reference plane in the height direction, and the detection table 1 is machined with a hole array of 120 positioning holes with a spacing of 100mm×100mm along the X coordinate direction and the Y coordinate direction.

[0055] The bracket 5 is composed of a base and a column, the column is square, and there are 5 positioning holes equidistantly arranged along the height direction, and the hole spacing is 100mm. The distance between the two positioning holes is 50mm; there are two positioning holes ...

Embodiment 2

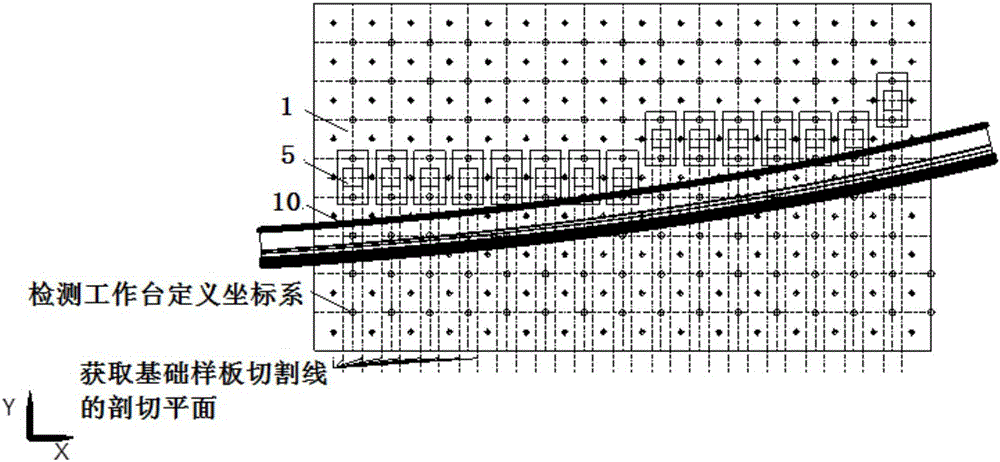

[0057] The detection of the workpiece should first determine the positioning datum of the workpiece 10 to be inspected. The positioning datum should ensure that the workpiece 10 is accurately positioned on the detection device and is easy to measure, and the workpiece 10 should be placed on the detection device stably and reliably. Since the three-dimensional bending part of the profile belongs to the elongated bending part, the workpiece 10 is generally formed by drawing, bending and twisting, and there is generally neither a plane nor a straight line thereon. Therefore, we choose the cross-sectional profile of the three-dimensional mathematical model of the workpiece as the positioning reference of the detection device. Since the workpiece is generally arc-shaped, in order to ensure the stability of the workpiece, at least three cross-sectional profiles should be selected as the positioning reference.

[0058] A three-dimensional mathematical model of a three-dimensional ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com