Real-time automatic monitoring method for wireless torsional force wrench

A torque wrench, automatic monitoring technology, applied in the direction of measuring torque/torsion force, signal transmission system, instrument, etc. during tightening, can solve the problems of scaffolding collapse, bolt fastening force not up to standard, construction workers being lazy, etc., to prevent Bolt tightening force is too large or too small, the effect of strengthening work efficiency management and facilitating understanding and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

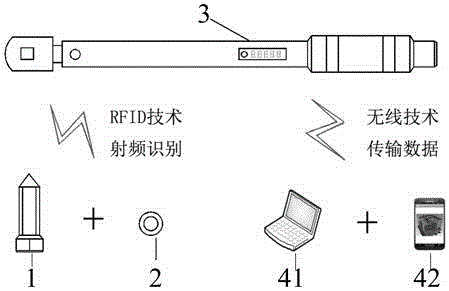

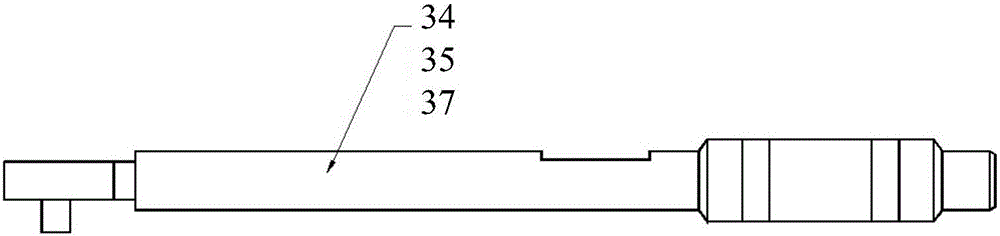

[0026] Such as Figure 1~3 As shown, the present invention provides a real-time automatic monitoring method for a wireless torque wrench, including:

[0027] Step S1, a professional factory mass-produces scaffold node bolts 1 with electronic tags 2, and wireless torque wrench 3 based on RFID technology;

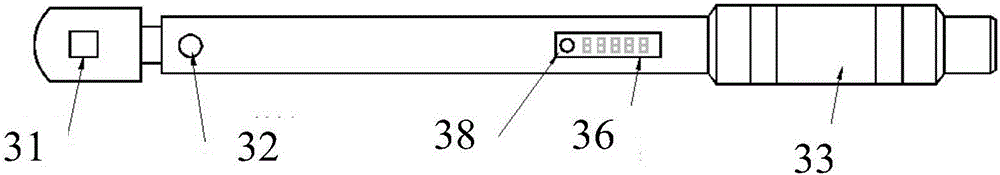

[0028] Step S2, the operator holds the wireless torque wrench 3 to fasten the bolts 1 of each scaffold node in a certain order, one operator corresponds to a numbered wireless torque wrench 3, and the digital display module 36 of the wireless torque wrench 3 displays the currently operated tightening Solid force; here, an operator corresponds to a numbered wireless torque wrench, which is convenient for follow-up tracking and ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com