Intelligent circulating liquid feeding device and intelligent circulating liquid feeding method for lining accelerated corrosion test

An accelerated corrosion test and corrosive liquid technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of low reliability, large error of experimental data, and inability to load Test and other issues to achieve the effect of ensuring the concentration and test results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

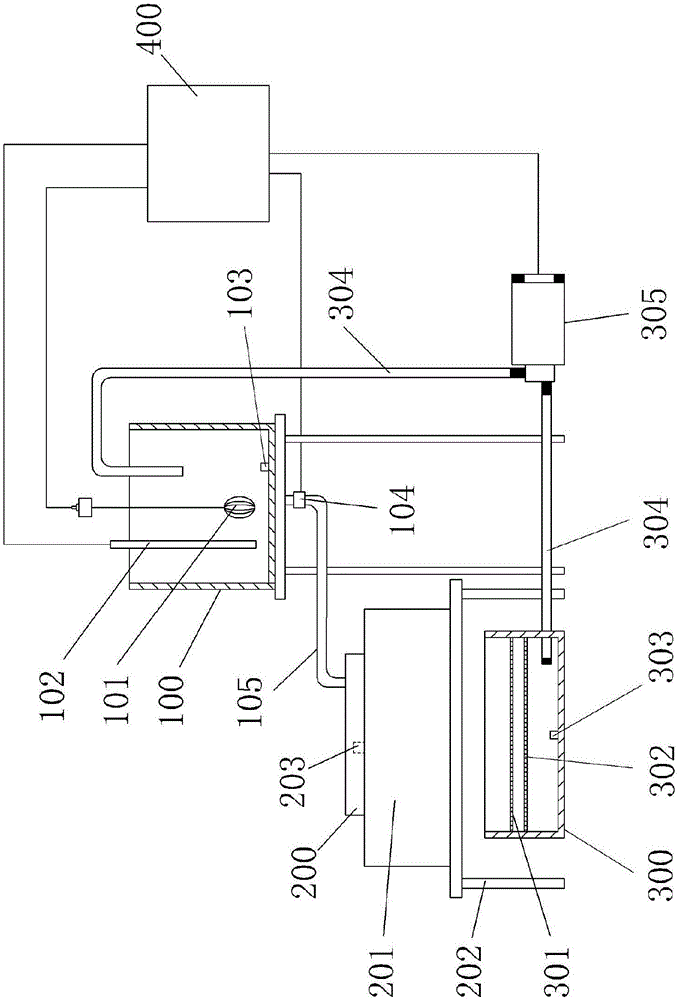

[0037] figure 1 It is shown that a specific embodiment of the present invention is a circulating intelligent liquid supply device for lining accelerated corrosion test, which consists of:

[0038] The lining 201 is placed on the lining support 202, and the top surface of the middle part of the lining 201 is installed with a bottom seepage corrosion solution tank 200, the bottom of the corrosion solution tank 200 is provided with a water pressure sensor 203, and the liquid outlet end of the liquid supply pipe 105 is placed in the corrosion tank 200. In the liquid tank 200;

[0039]A liquid supply tank 100 is arranged above the lining 201, and an electric agitator 101, a solute concentration meter 102, and a water pressure sensor 103 are arranged in the liquid supply tank 100, and the liquid supply port at the bottom of the liquid supply tank 100 and the liquid inlet of the liquid supply pipe 105 end connection, a flow control valve 104 is connected in series on the liquid supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com