Sunglass lens

A technology of sunglasses and lenses, applied in the field of sunglasses lenses, can solve the problems of impolite wearer, discomfort of communicators, light pollution, etc., and achieve the effect of improving light pollution, reducing reflection effect, and avoiding impoliteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

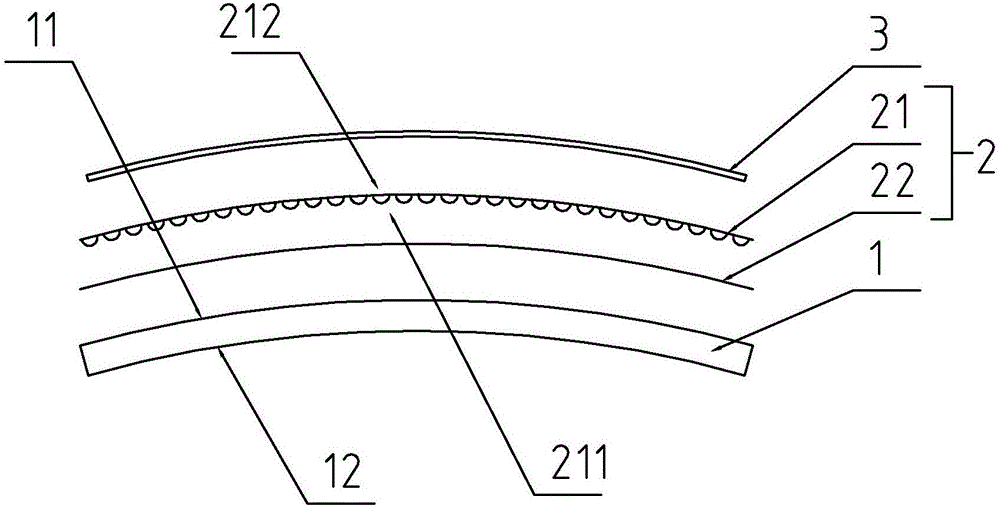

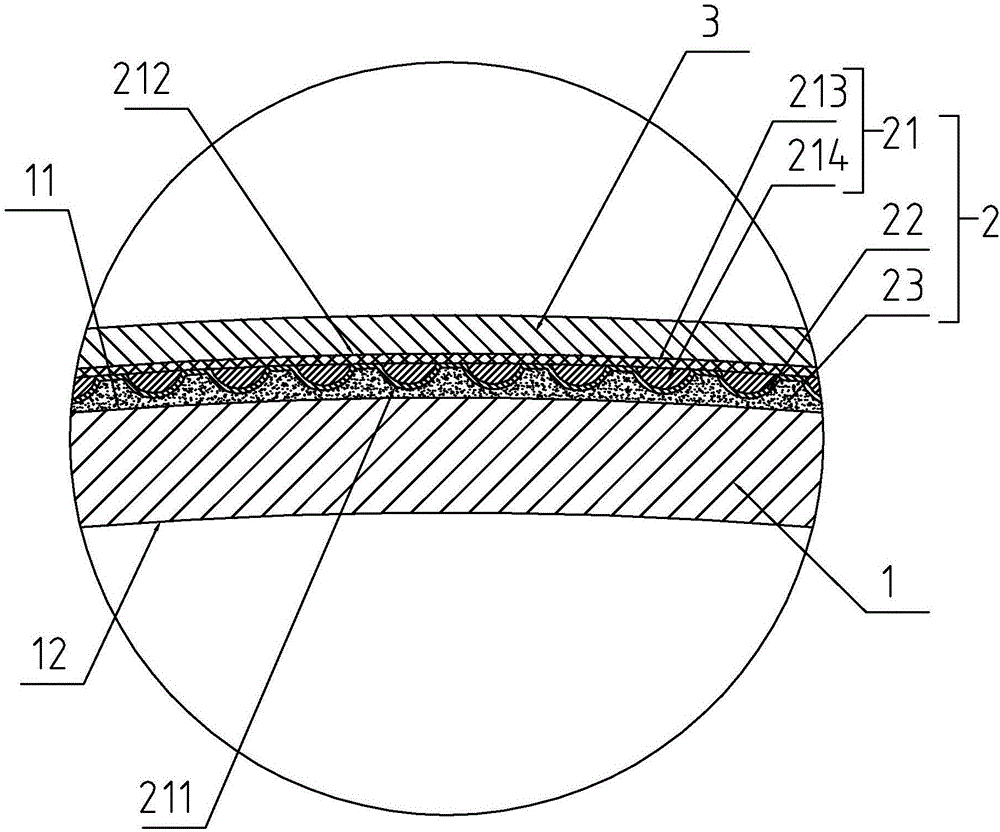

[0026] Embodiment one: refer to figure 1As shown, when the matte layer 2 is attached to the arc-shaped convex surface 11, the smooth surface 212 is bonded with the hard TAC film 3 to form, the color electroplating layer 22 is plated on the hazy matte surface 211, and the matte sheet 21 faces the color electroplating layer One side of 22 is then bonded with the curved convex surface 11 through the glue filling layer 23; when the light is irradiated from the convex side of the lens to the concave side, the light will be directly folded back or diffused through the matte layer 2, and the line of sight is from the lens. The line of sight is transmitted when projecting from the concave side to the convex side. Its principle is: the color electroplating layer 22 is to plate a layer of metal layer with color on the foggy surface 211, and this metal layer belongs to high refraction material; The metal layer particles on the electroplating are about 0.1-0.2um in diameter, and the meta...

Embodiment 2

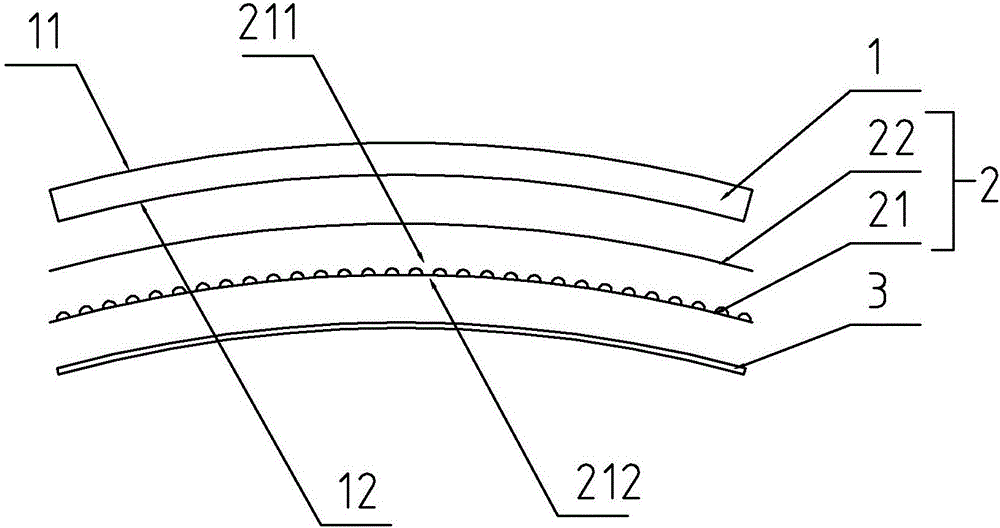

[0027] Embodiment two: refer to figure 2 As shown, when the matte layer 2 is attached to the arc-shaped concave surface 12, the smooth surface 212 and the hard TAC film 3 are bonded to form, the color electroplating layer 22 is plated on the hazy matte surface 211, and the matte sheet 21 faces the color electroplating layer One side of 22 is bonded with the curved concave surface 12 through the glue filling layer 23 to form; when light is irradiated from the convex side of the lens to the concave side, the light will be directly folded back or diffused through the matte layer 2, and the line of sight from the lens The line of sight is transmitted when projecting from the concave side to the convex side. Although the principle is similar to when the matte layer 2 is attached to the curved convex surface 11, it is also because the light is directly irradiated onto the electroplating layer after the curved light filtering of the base layer 1 of the mother sheet, and the light is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com