A system and method for order dispatch scheduling and mixed product sorting

An order and product technology, applied in the field of order dispatch scheduling and mixed product sorting system, can solve the problems of large demand for products in flexible production lines, difficulty in determining the optimal insertion point for new customers, and difficulty in allocating flexible production lines, etc. Real-time collection and transmission, reducing the total setup time, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

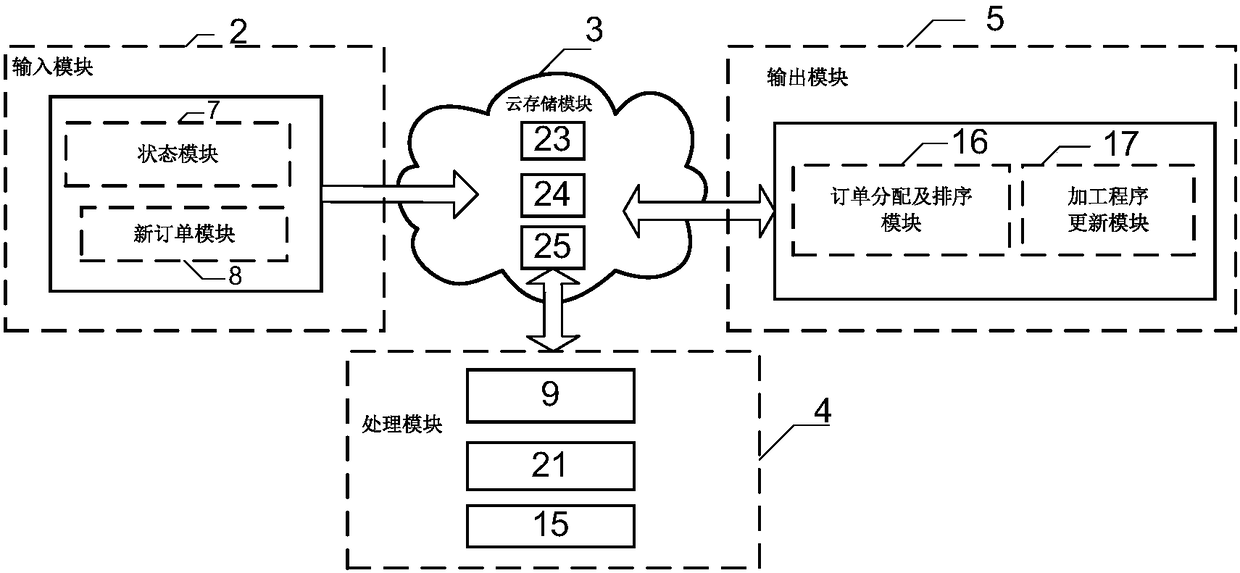

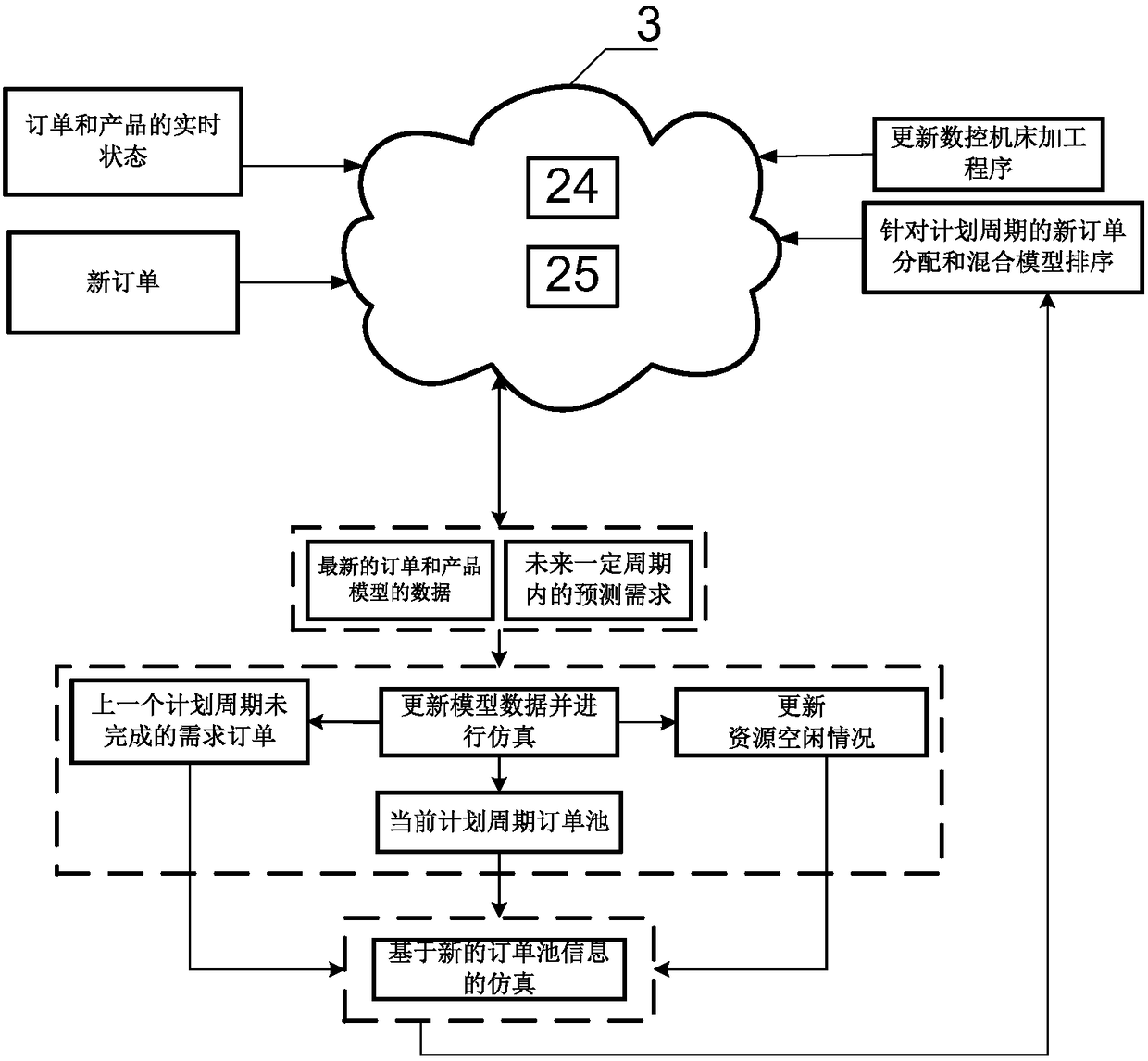

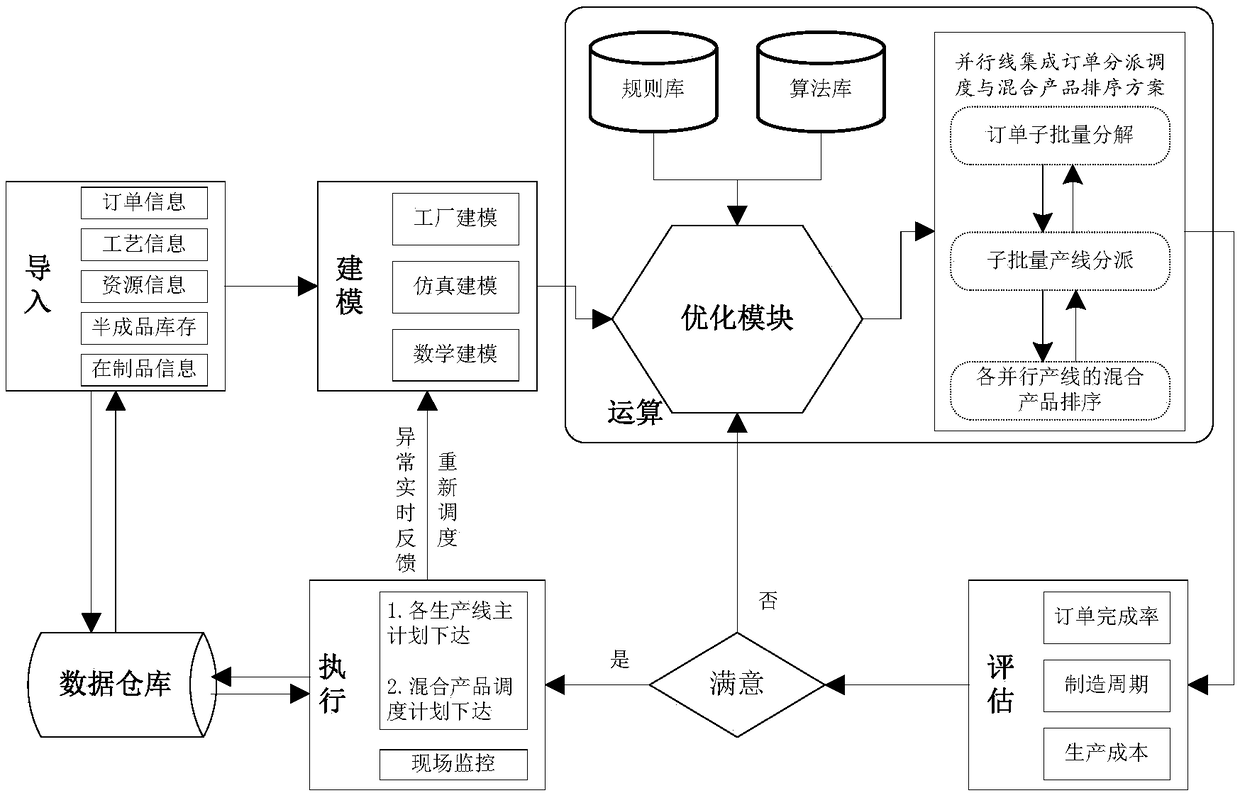

[0047] In the embodiment, taking the automated flexible production line in the automobile manufacturing industry as an example, the order dispatching scheduling and mixed product sorting system provided by the present invention is described in detail; the order dispatching scheduling and mixed product sorting system provided in the embodiment, its system block diagram is as follows figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com