Automatic guide transport vehicle AGV, and motion control method and apparatus thereof

A technology for automatically guiding and transporting vehicles, applied in the field of logistics, can solve the problems of wasting operation time, difficult parking, stable accuracy and precision, and low rhythm, and achieve the effect of reducing time waste, improving work efficiency, and improving parking accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

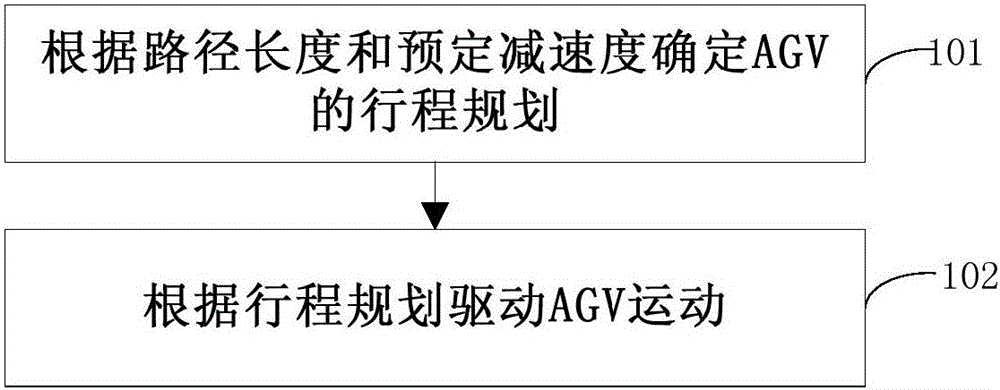

[0039] The flowchart of an embodiment of the AGV motion control method of the present invention is as figure 1 shown.

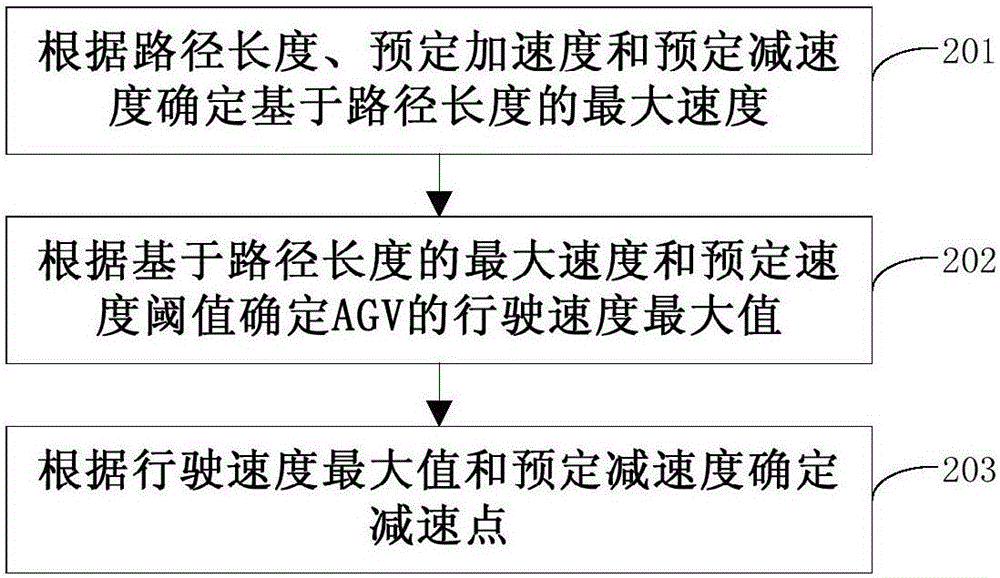

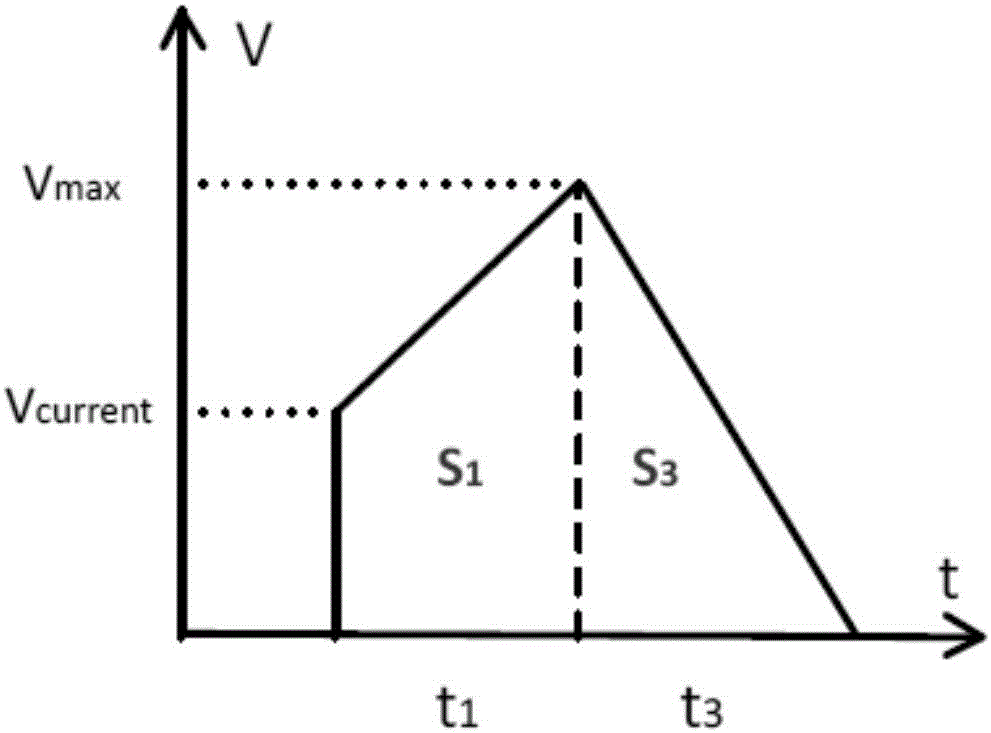

[0040] In step 101, the travel plan of the AGV is determined according to the path length and the predetermined deceleration. In one embodiment, the planning can be carried out according to the path length and the deceleration of the vehicle, and the driving speed and deceleration distance conforming to the travel length can be set to generate a travel plan. In one embodiment, the maximum travel speed and the deceleration point can be included in the travel plan, so as to ensure that the AGV reaches the destination accurately, while shortening the time as much as possible and improving efficiency.

[0041] In step 102, the AGV is driven to move according to the travel plan. In one embodiment, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com