Embedded type double-process supercritical water reactor fuel assembly

A supercritical water reactor and fuel assembly technology, applied in reactor fuel elements, nuclear engineering, reactors, etc., can solve problems such as low average density of coolant, complex design of the superstructure of the core, and influence on the intrinsic safety of the core, etc., to achieve Less difficulty in physical design, improved fuel economy, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

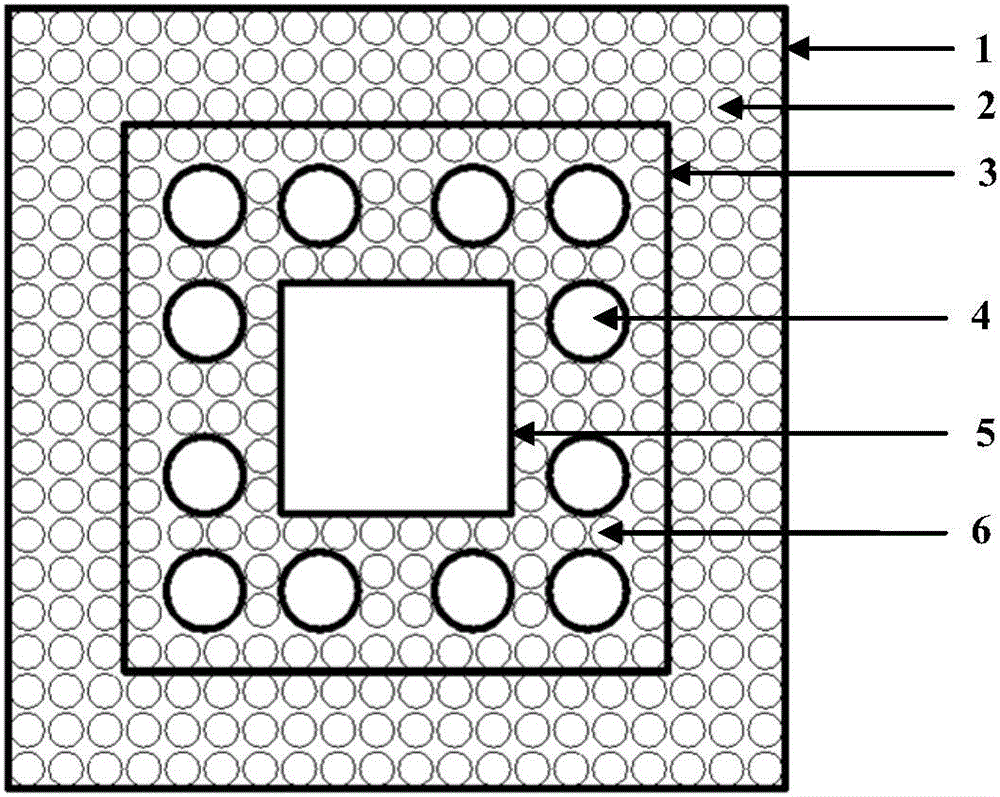

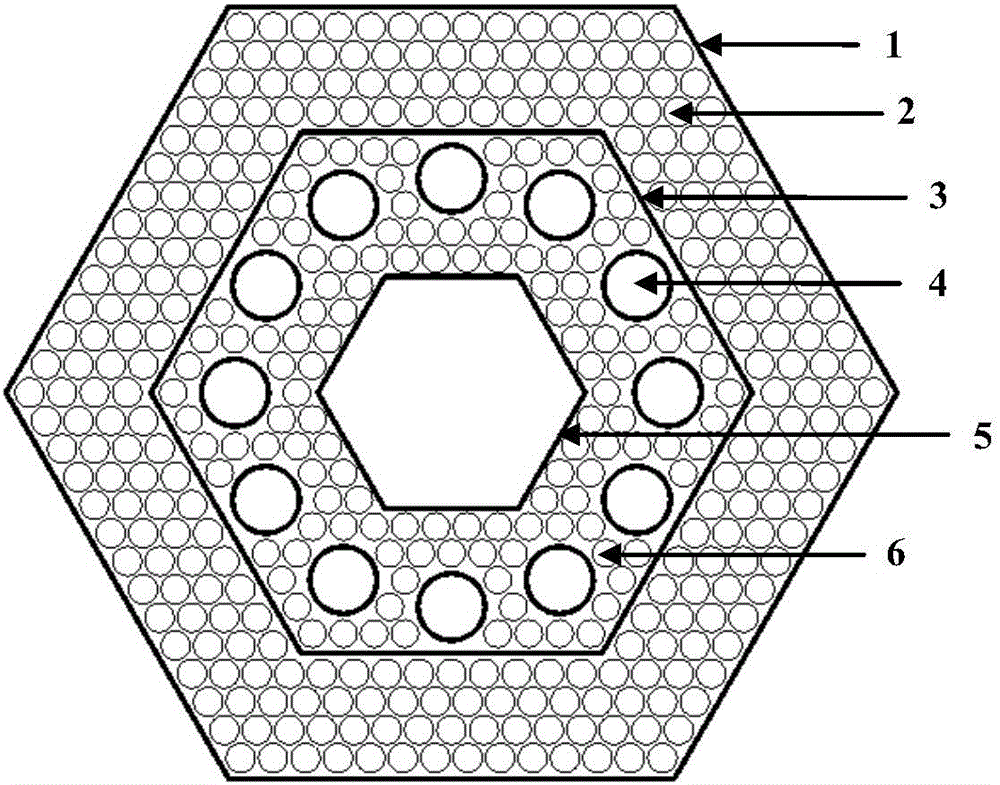

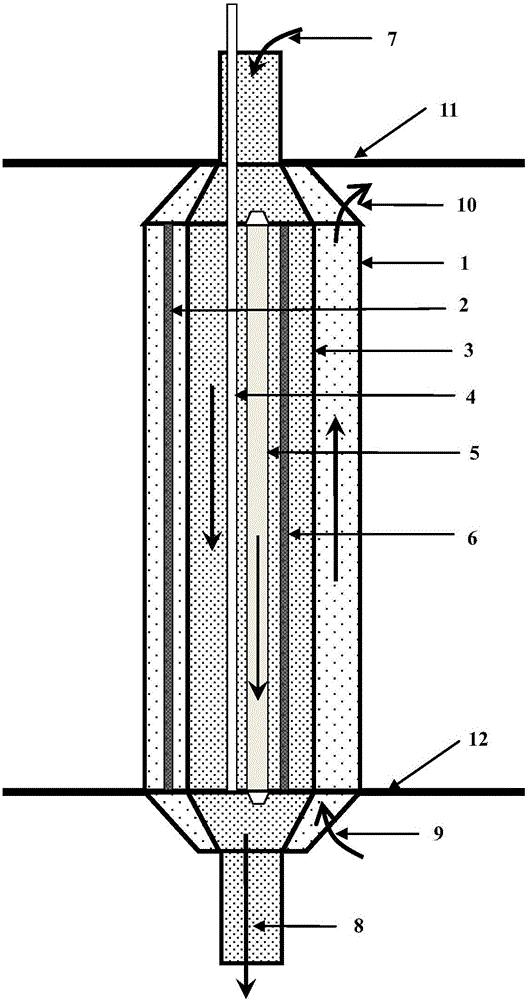

[0033] Such as Figure 1 to Figure 3 As shown, an embedded double-flow supercritical water reactor fuel assembly includes a fuel rod and a guide tube 4, and also includes a component box 1, a water rod box 5 and a heat insulation box 3, and the component box 1 and the heat insulation box 3 All are tubular structures, and the component box 1, heat insulation box 3, guide pipe 4, and fuel rods are in a parallel relationship with each other;

[0034] The component box 1 is sleeved on the outside of the heat insulation box 3, and both ends of the component box 1 are located between the two ends of the heat insulation box 3;

[0035] Fuel rods are arranged in the heat insulation box 3 and in the space between the outer wall of the heat insulation box 3 and the inner wall of the component box 1, and the guide pipe 4 is arranged in the heat insulation box 3;

[0036] The second process coolant outlet 10 and the second process coolant inlet 9 are also arranged on the component box 1,...

Embodiment 2

[0044] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, in order to obtain a larger water rod in the water rod box 5, the flow rate of the coolant in the water rod box 5 is reduced at the same time, so as to realize the condition that the water density reactivity coefficient of the component is positive, that is, to realize the guarantee Under the condition of component neutron moderation ability, increase the flow rate of the coolant in the first process other than the water rod box 5, and strengthen the heat transfer to the fuel rods 6 in the first process area. In the two ends of the water rod box 5, The outer shape of at least one end is tapered, and the small end face of the tapered end of the water stick box 5 is the end face of the water stick box 5 . In this structure, at least one end of the water stick box 5 is set to a big and small head shape, and the small end of the big and small head is positioned at the ...

Embodiment 3

[0052] This embodiment further limits this case on the basis of any one of the technical solutions provided by any one of the above embodiments: since the fuel assembly works in a high-temperature environment, in order to facilitate the shape retention of each component in this fuel assembly, the assembly box 1. The cross-sectional shapes of the heat insulation box 3, the guide pipe 4, and the water rod box 5 are all centrosymmetric figures.

[0053] As a technical solution that facilitates manufacture and installation, and is convenient for controlling the position of the center of gravity, the center line of the water rod box 5 is collinear with the center line of the heat insulation box 3, and the center line of the heat insulation box 3 is in line with the center line of the component box 1. The centerlines are collinear. Further, it is preferred that the arrangement of the fuel rods is also symmetrical to the center, and the axis of symmetry is the center line of the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com