High-stability PTC thermosensitive assembly capable of improving maintenance current

A technology with high stability and maintaining current, applied in the direction of resistance terminals/electrodes, resistors with positive temperature coefficients, etc., to achieve the effect of diversified processing methods, large maintaining current, and low initial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

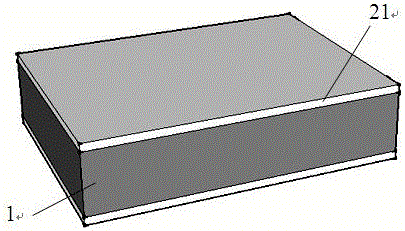

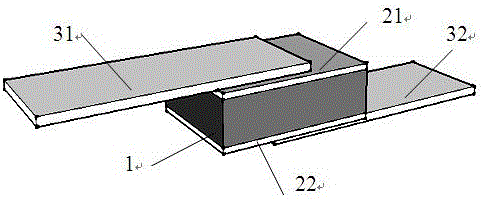

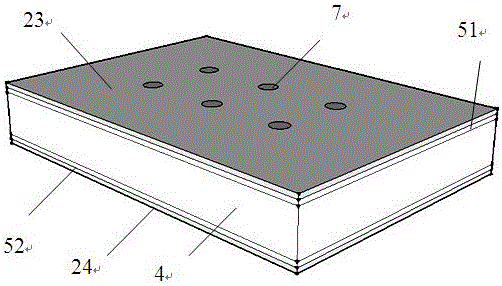

Image

Examples

Embodiment 1

[0048] The steps of preparing the conductive composite material and the PTC thermosensitive element are the same as those of the comparative example, but the conductive filler is replaced by a titanium carbide solid solution with a particle size of less than 10 μm, a volume resistivity of 42 μΩ.cm, and a thermal conductivity of 18W / (m.K ).

Embodiment 2

[0050] The steps of preparing conductive composite materials and PTC thermal elements are the same as in Example 2, but on the basis of Example 1, the pure nickel electrode foil is replaced with pure copper electrode foil, the resistivity is 1.7μΩ.cm, and the thermal conductivity is 380 W / (m.K);

Embodiment 3

[0052] The steps of preparing the conductive composite material and the PTC thermal element are the same as in Example 3, but on the basis of Example 2, the PTC chip size is punched into 2.4*3.6mm single element pieces;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com