Multi-stage circulatory forming and activating process for lead-acid storage battery for storing energy

A lead-acid battery, multi-stage technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery repair/maintenance, etc., can solve the problems of unable to remove unqualified plates, poor battery consistency, and low production efficiency. Achieve the effect of improving hydrogen-oxygen recombination efficiency, short formation time and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The following examples and performance tests further illustrate the content of the present invention and its beneficial effects.

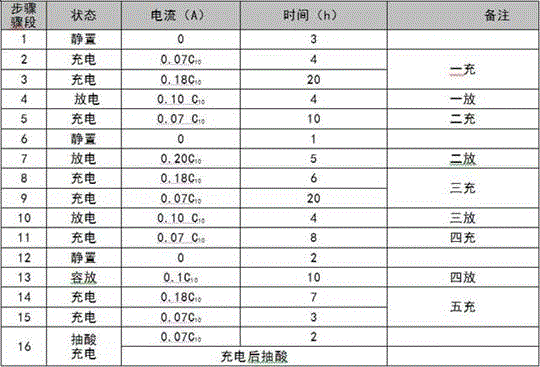

[0008] The specific operations of this embodiment are as follows:

[0009]

[0010] Performance Testing:

[0011] 1. Battery preparation

[0012] Positive plate: Stir and mix the lead powder and polypropylene fiber in a dry state for 5 minutes, add deionized water at a constant speed while stirring within 5 minutes, continue stirring for 8 minutes, then add sulfuric acid, add acid for 12 minutes, and continue stirring for 10 minutes. Make lead paste. During the preparation process, the temperature of the paste is controlled at 60-75°C, and the temperature is controlled at 60-62°C when the paste is produced, and cured at 65°C for 48 hours.

[0013] Negative plate: Lead powder, activated carbon, lignin, humic acid, polypropylene fiber are stirred and mixed for 7 minutes in a dry state, and deionized water is added at a constant speed while stirring wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com