DP3 deepwater drilling ship closed loop high voltage distribution system

A deep-water drilling and high-voltage power distribution technology, which is applied in the direction of electrical components, circuit devices, and AC network circuits, can solve problems such as the lack of closed-loop high-voltage power distribution systems, achieve safe and reliable operation and intelligent management, and reduce host operation. Maintenance time and improvement of power supply reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

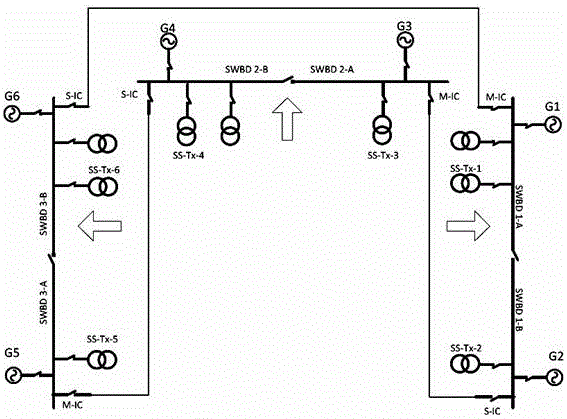

[0035] Embodiment 1: as attached figure 1 As shown, the power distribution system is an 11kV high-voltage power supply and distribution system, including: six 7370kWe / 11kV / 60Hz diesel generators, three 11kV high-voltage distribution boards that can be connected in a ring, six sets of electric propulsion systems, and four drilling frequency conversion transformers , six marine auxiliary transformers, and three drilling auxiliary transformers; in the power distribution system, diesel generators and high-voltage distribution boards are redundantly configured in terms of capacity and number, and are arranged in at least two independent A60 divided watertight compartments ; Diesel generators G1 and G2, diesel generators G3 and G4, diesel generators G5 and G6 are respectively located in different host rooms, and the three host rooms are divided by A60; the three high-voltage distribution boards are located in different Between the high-voltage distribution boards, the three high-volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com