Synchronous rectification control circuit

A synchronous rectification and control circuit technology, applied in control/regulation systems, emergency protection circuit devices, electrical components, etc., can solve the problems of inability to support continuous mode, work in the linear region, large loss, etc., to simplify peripheral application circuits, The effect of reducing the application device and preventing the explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

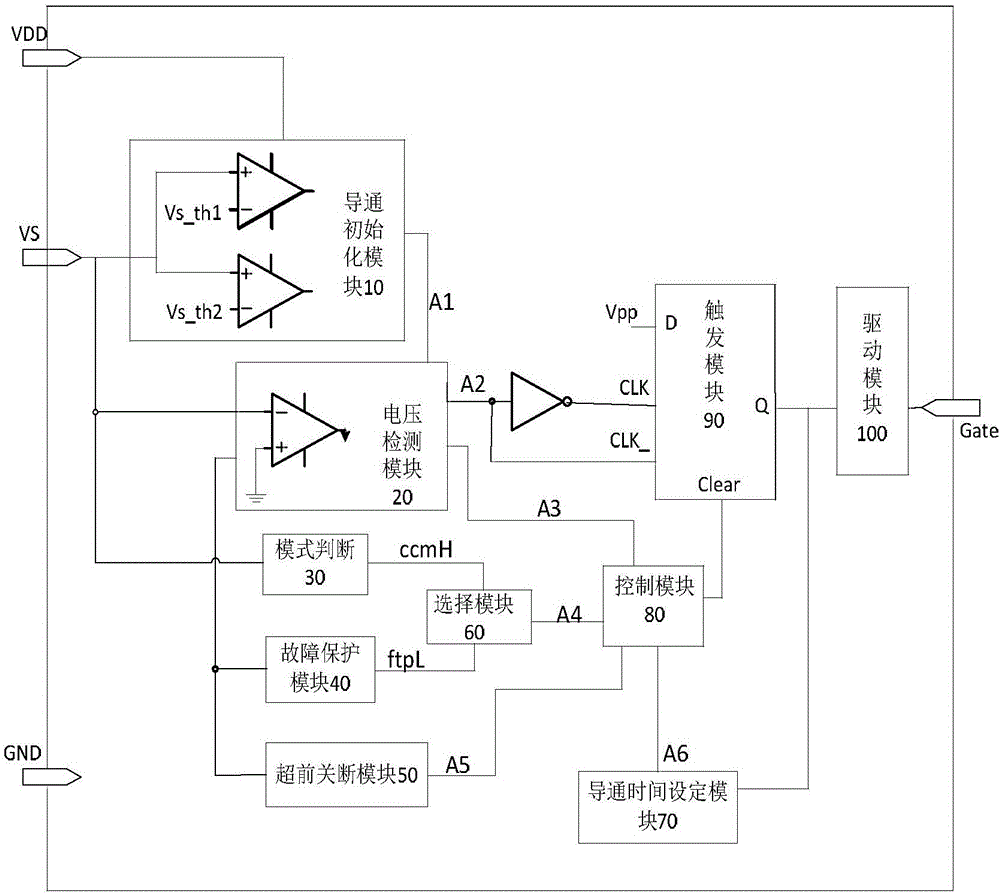

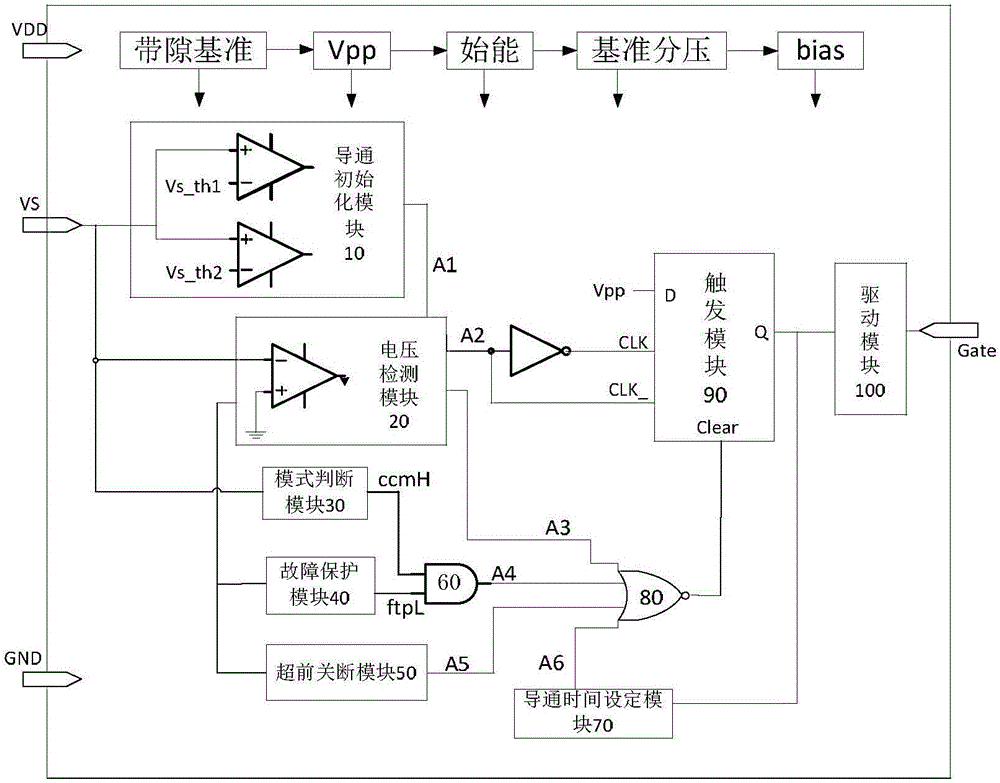

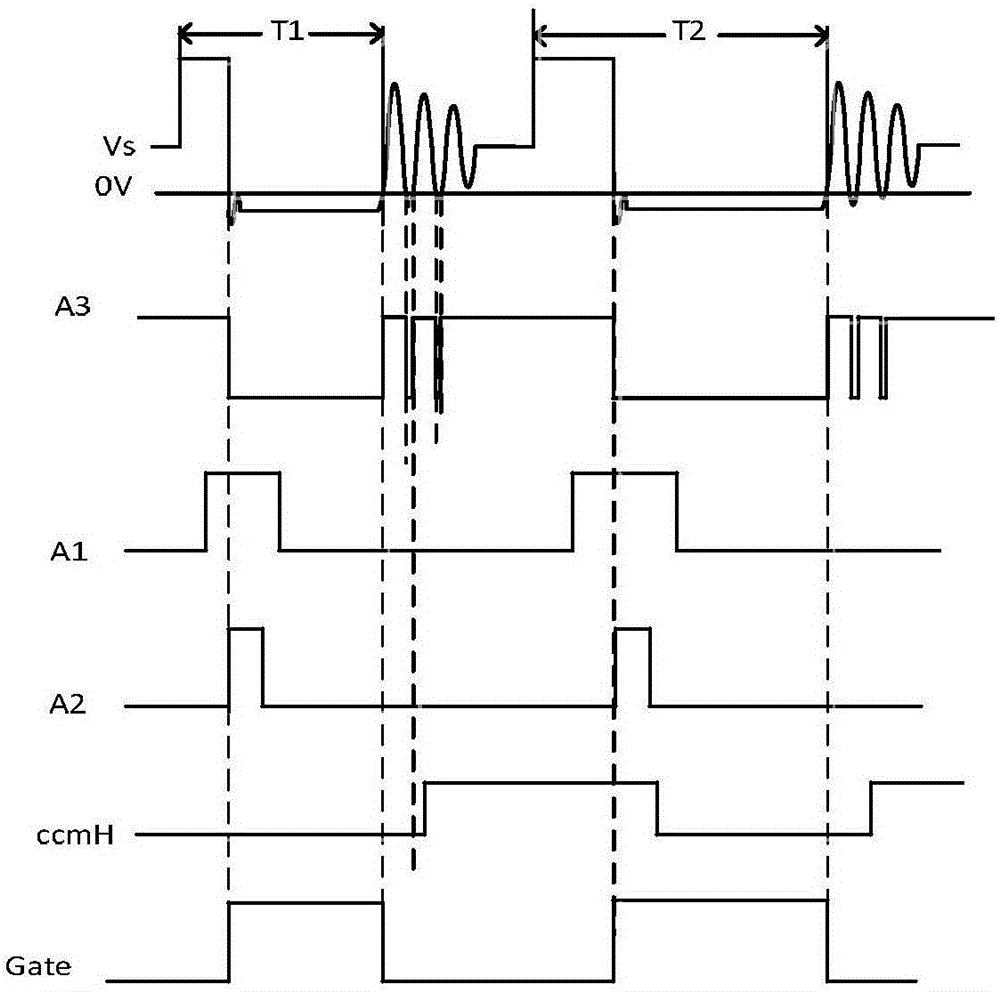

[0033] figure 1 Shown is a schematic structural diagram of the synchronous rectification chip of the present invention, the synchronous rectification chip includes: a conduction initialization module 10, a voltage detection module 20, a mode judgment module 30, a fault protection module 40, an advanced shutdown module 50, a selection module 60, A time setting module 70 , a control module 80 , a trigger module 90 , and a driving module 100 . The conduction initialization module 10, the voltage detection module 20, and the mode judgment module 30 are respectively connected to the voltage input terminal; the conduction initialization module 10 is connected to the voltage detection module 20, and the voltage detection module 20 is respectively connected to the fault The protection module 40, the advance shutdown module 50, the control module 80, and the trigger module 90; the mode judgment module 30 and the fault protection module 40 are connected to the input end of the selection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com