Method and system for decontaminating caps or necks of containers by pulsed electron bombardment

A technology of electron bombardment, decontamination system, applied in the directions of bottle/container cap, container closure with cap, closure, etc., can solve problems such as cross-linking phenomenon, deterioration, odor migration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

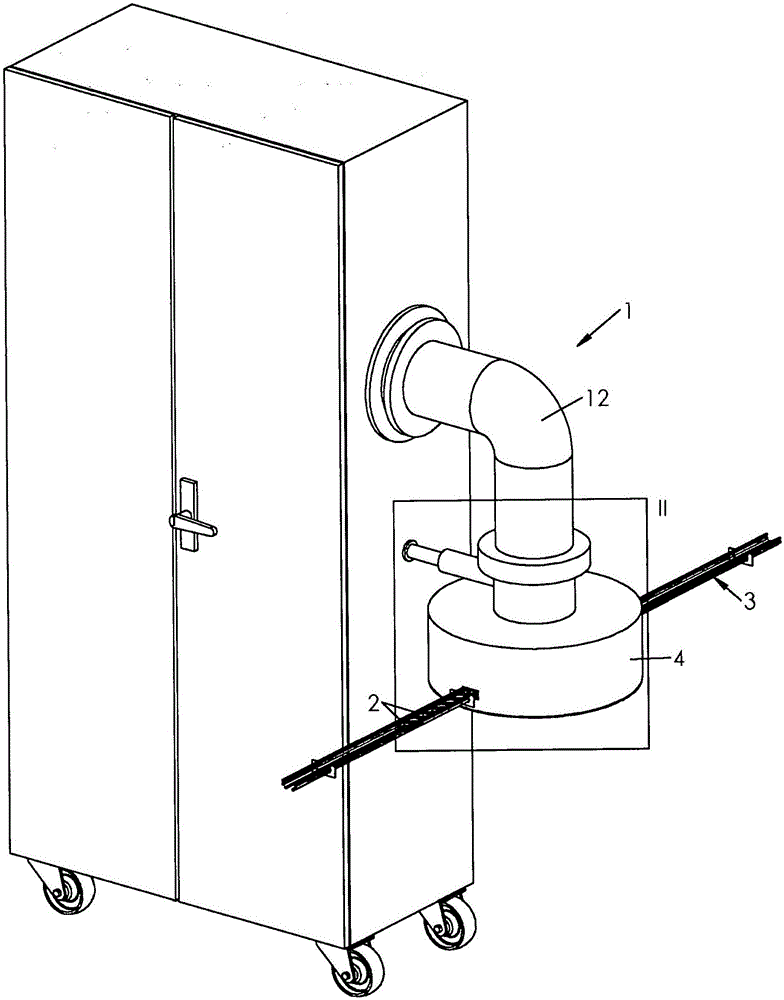

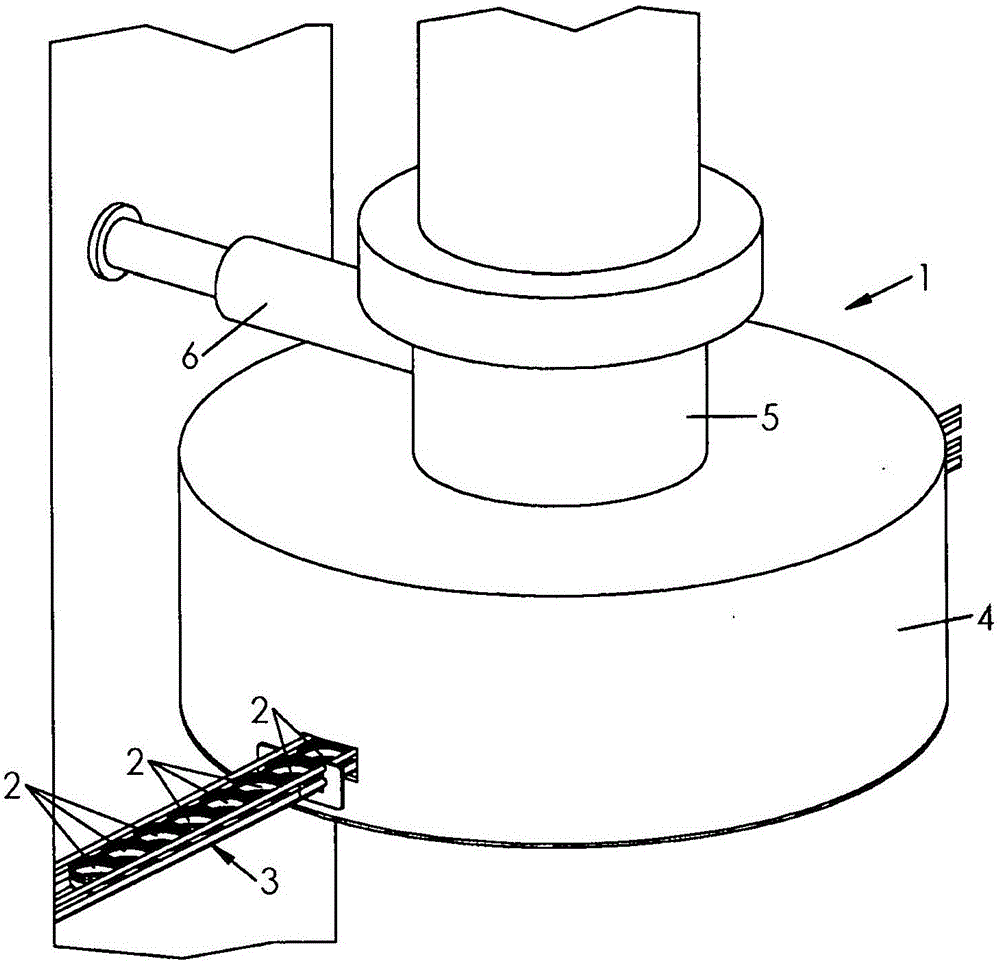

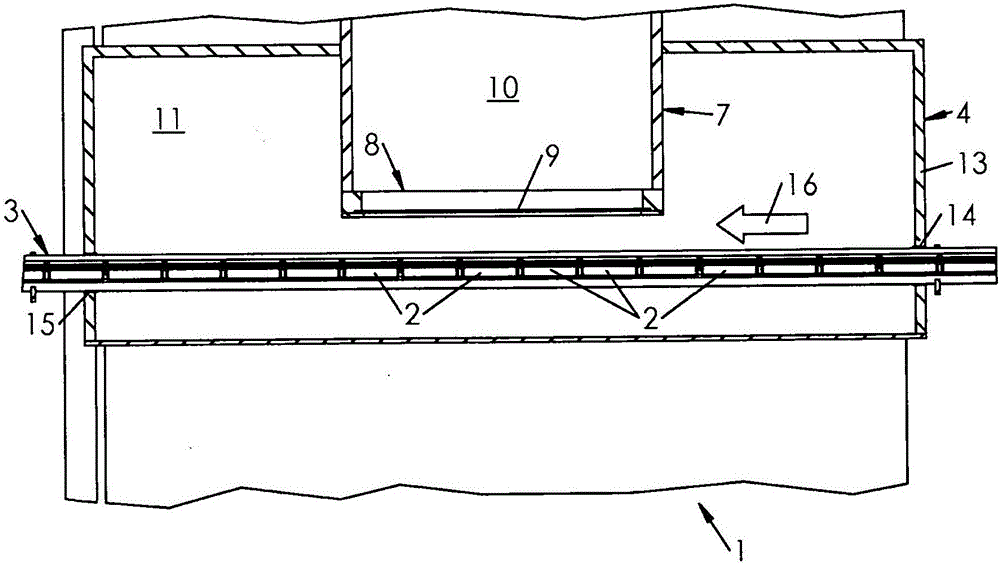

[0034] figure 1 System 1 is shown, which has an electron gun that produces a high intensity stream of electrons. Advantageously, the electron flow generated at the outlet of the electron gun is a pulsed electron flow / beam for bombarding the container cap 2 and / or the neck to decontaminate the container cap and / or the neck. Different embodiments are described here which are suitable for the cap 2 , but it is obvious that these embodiments are also fully suitable for the aforementioned container necks. The covers 2 are advanced by means of a transport device 3 into a sterilization chamber 4 with a pulsed electron gun, ie a closed sterile chamber. Forwarding here refers to continuous delivery in time. According to another embodiment, the cover 2 is positioned in the sterilization chamber 4 sequentially, ie step by step, for example by means of the conveying device 3 . The use of all these elements is detailed below.

[0035] figure 2 yes figure 1 Enlarged detail of region ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com